Общий каталог Mitsubishi 2020 - 2021 - страница 1628

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

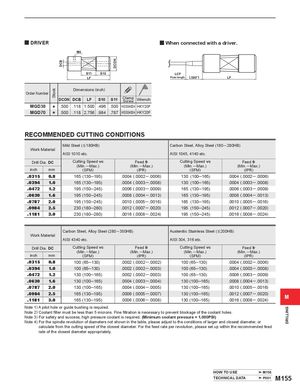

Stock DCB DCON DRILLING y DRIVER y When connected with a driver. M4 S11 S10 LCF LF Flute length (.590") LF Dimensions (inch) Order Number DCON DCB LF S10 S11 ClampScrewWrench MGD38 s .500 .118 1.500 .496 .500 HSS04004 HKY20F MGD70 s .500 .118 2.756 .984 .787 HSS04004 HKY20F RECOMMENDED CUTTING CONDITIONS Mild Steel ( < 180HB) Carbon Steel, Alloy Steel (180 ─ 280HB) Work Material AISI 1010 etc. AISI 1045, 4140 etc. Drill Dia. DC Cutting Speed vc Feed fr Cutting Speed vc Feed fr (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) inch mm (SFM) (IPR) (SFM) (IPR) .0315 0.8 165 (130─195) .0004 (.0002 ─ .0006) 130 (100─165) .0004 (.0002 ─ .0006) .0394 1.0 165 (130─195) .0004 (.0003 ─ .0008) 130 (100─165) .0004 (.0003 ─ .0008) .0472 1.2 195 (150─245) .0006 (.0003 ─ .0009) 165 (130─195) .0006 (.0003 ─ .0009) .0630 1.6 195 (150─245) .0008 (.0004 ─ .0013) 165 (130─195) .0008 (.0004 ─ .0013) .0787 2.0 195 (150─245) .0010 (.0005 ─ .0016) 165 (130─195) .0010 (.0005 ─ .0016) .0984 2.5 230 (180─280) .0012 (.0007 ─ .0020) 195 (150─245) .0012 (.0007 ─ .0020) .1181 3.0 230 (180─280) .0016 (.0008 ─ .0024) 195 (150─245) .0016 (.0008 ─ .0024) Carbon Steel, Alloy Steel (280 ─ 350HB) Austenitic Stainless Steel ( < 200HB) Work Material AISI 4340 etc. AISI 304, 316 etc. Drill Dia. DC Cutting Speed vc Feed fr Cutting Speed vc Feed fr (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) inch mm (SFM) (IPR) (SFM) (IPR) .0315 0.8 100 (65─130) .0002 (.0002 ─ .0002) 100 (65─130) .0004 (.0002 ─ .0006) .0394 1.0 100 (65─130) .0002 (.0002 ─ .0003) 100 (65─130) .0004 (.0003 ─ .0008) .0472 1.2 130 (100─165) .0002 (.0002 ─ .0003) 100 (65─130) .0006 (.0003 ─ .0009) .0630 1.6 130 (100─165) .0004 (.0003 ─ .0004) 130 (100─165) .0008 (.0004 ─ .0013) .0787 2.0 130 (100─165) .0004 (.0004 ─ .0005) 130 (100─165) .0010 (.0005 ─ .0016) .0984 2.5 165 (130─195) .0006 (.0005 ─ .0007).11813.0165 (130─195).0006 (.0006 ─ .0008)130 (100─165)130 (100─165).0012 (.0007 ─ .0020).0016 (.0008 ─ .0024)M Note 1) A pilot hole or guide bushing is required. Note 2) Coolant filter must be less than 5 microns. Fine filtration is necessary to prevent blockage of the coolant holes. Note 3) For safety and success, high pressure coolant is required. (Minimum coolant pressure = 1,000PSI) Note 4) For the spindle revolution of diameters not shown in the table, please adjust to the conditions of larger and closest diameter, or calculate from the cutting speed of the closest diameter. For the feed rate per revolution, please set up within the recommended feed rate of the closest diameter appropriately. HOW TO USE M156 TECHNICAL DATA P001 M155