Общий каталог Mitsubishi 2020 - 2021 - страница 1600

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

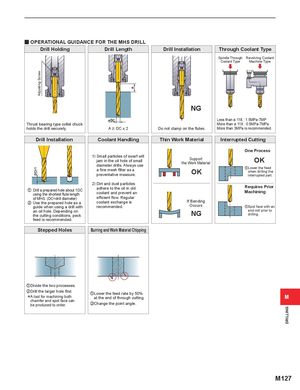

D1CD1x1 Adjusting Screw A DRILLING y OPERATIONAL GUIDANCE FOR THE MHS DRILL Drill Holding Drill Length Drill Installation Through Coolant Type Spindle Through Revolving Coolant Coolant Type Machine Type NG øDC1 Less than ø.118 : 1.5MPa-7MP Thrust bearing type collet chuck More than ø.118 : 0.5MPa-7MPa holds the drill securely. A > DC x 2 Do not clamp on the flutes. More than 3MPa is recommended. Drill Installation Coolant Handling Thin Work Material Interrupted Cutting One Process 1) Small particles of swarf willjam in the oil hole of smalldiameter drills. Always usea fine mesh filter as apreventative measure.Supportthe Work MaterialOKzLower the feedOKwhen drilling theinterrupted part. 2) Dirt and dust particles z Drill a prepared hole about 1DCusing the shortest flute lengthadhere to the oil in oldcoolant and prevent an Requires PriorMachining of MHS. (DC=drill diameter) efficient flow. Regularx Use the prepared hole as acoolant exchange isguide when using a drill withrecommended.If BendingOccurszSpot face with an an oil hole. Depending onthe cutting conditions, peck NG end mill prior todrilling. feed is recommended. Stepped Holes Burring and Work Material Chipping zDivide the two processes. xDrill the larger hole first.*A tool for machining bothchamfer and spot face canbe produced to order.zLower the feed rate by 50%at the end of through cutting.xChange the point angle.M M127