Общий каталог Mitsubishi 2020 - 2021 - страница 1599

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

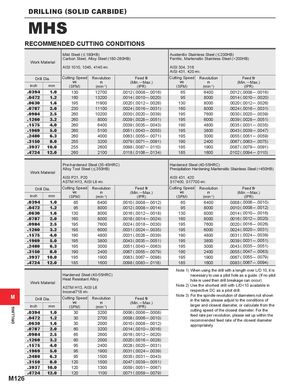

DRILLING (SOLID CARBIDE) MHS RECOMMENDED CUTTING CONDITIONS Mild Steel ( < 180HB) Austenitic Stainless Steel ( < 200HB) Carbon Steel, Alloy Steel (180-280HB) Ferritic, Martensitic Stainless Steel (>200HB) Work Material AISI 1010, 1045, 4140 etc. AISI 304, 316 AISI 431, 420 etc. Drill Dia. Cutting Speed Revolution Feed fr Cutting Speed Revolution Feed fr vc n (Min. ─ Max.) vc n (Min. ─ Max.) inch mm (SFM) (min-1) (IPR) (SFM) (min-1) (IPR) .0394 1.0 130 12700 .0012 (.0008 ─ .0016) 65 6400 .0012 (.0008 ─ .0016) .0472 1.2 160 13200 .0014 (.0010 ─ .0020) 95 8000 .0014 (.0010 ─ .0020) .0630 1.6 195 11900 .0020 (.0012 ─ .0026) 130 8000 .0020 (.0012 ─ .0026) .0787 2.0 230 11100 .0024 (.0016 ─ .0031) 160 8000 .0024 (.0016 ─ .0031) .0984 2.5 260 10200 .0030 (.0020 ─ .0039) 195 7600 .0030 (.0020 ─ .0039) .1260 3.2 260 8000 .0039 (.0028 ─ .0051) 195 6000 .0039 (.0028 ─ .0051) .1575 4.0 260 6400 .0039 (.0035 ─ .0043) 190 4800 .0035 (.0031 ─ .0035) .1969 5.0 260 5100 .0051 (.0043 ─ .0055) 195 3800 .0043 (.0039 ─ .0047) .2480 6.3 260 4000 .0063 (.0055 ─ .0071) 195 3000 .0055 (.0051 ─ .0059) .3150 8.0 255 3200 .0079 (.0071 ─ .0091) 190 2400 .0067 (.0063 ─ .0075) .3937 10.0 255 2600 .0098 (.0087 ─ .0110) 195 1900 .0087 (.0079 ─ .0091) .4724 12.0 260 2100 .0118 (.0106 ─ .0134) 185 1600 .0102 (.0094 ─ .0110) Pre-hardened Steel (35-45HRC) Hardened Steel (40-55HRC) Alloy Tool Steel ( < 350HB) Precipitation Hardening Martensitic Stainless Steel (<450HB) Work Material AISI P21, P20 AISI 431, 420 ASTM H13, AISI L6 etc. S17400, S17700 etc. Drill Dia. Cutting Speed Revolution Feed fr Cutting Speed Revolution Feed fr vc n (Min. ─ Max.) vc n (Min. ─ Max.) inch mm (SFM) (min-1) (IPR) (SFM) (min-1) (IPR) .0394 1.0 65 6400 .0010 (.0008 ─ .0012) 65 6400 .0008 (.0006 ─ .0010) .0472 1.2 95 8000 .0012 (.0008 ─ .0014) 95 8000 .0010 (.0008 ─ .0012) .0630 1.6 130 8000 .0016 (.0012 ─ .0018) 130 8000 .0014 (.0010 ─ .0016) .0787 2.0 160 8000 .0018 (.0014 ─ .0024) 160 8000 .0016 (.0012 ─ .0020) .0984 2.5 195 7600 .0024 (.0018 ─ .0030) 195 7600 .0020 (.0016 ─ .0026) .1260 3.2 195 6000 .0031 (.0024 ─ .0035) 195 6000 .0024 (.0020 ─ .0031) .1575 4.0 190 4800 .0031 (.0028 ─ .0039) 190 4800 .0031 (.0024 ─ .0039) .1969 5.0 195 3800 .0043 (.0035 ─ .0051) 195 3800 .0039 (.0031 ─ .0051) .2480 6.3 195 3000 .0051 (.0043 ─ .0063) 195 3000 .0043 (.0035 ─ .0051) .3150 8.0 190 2400 .0067 (.0055 ─ .0079) 190 2400 .0055 (.0047 ─ .0063) .3937 10.0 195 1900 .0083 (.0067 ─ .0098) 195 1900 .0067 (.0055 ─ .0079) .4724 12.0 185 1600 .0098 (.0083 ─ .0118) 185 1600 .0083 (.0067 ─ .0094) Note 1) When using the drill with a length over L/D 10, it is Hardened Steel (40-55HRC) necessary to use a pilot hole as a guide. (If no pilot Heat Resistant AlloyWork MaterialASTM H13, AISI L6Inconel718 etc. hole is used then drill breakage can occur)Note 2) Use the shortest drill with L/D<10 available inrespective DC as a pilot drill. M Drill Dia. Cutting Speed Revolution Feed frvcn(Min. ─ Max.)inchmm(SFM)(min-1)(IPR)Note 3) For the spindle revolution of diameters not shownin the table, please adjust to the conditions oflarger and closest diameter, or calculate from the .0394 1.0 30 3200 .0006 (.0006 ─ .0008).04721.2302700.0008 (.0006 ─ .0010).06301.6302000.0010 (.0008 ─ .0012)cutting speed of the closest diameter. For thefeed rate per revolution, please set up within therecommended feed rate of the closest diameterappropriately. .0787 2.0 60 3200 .0014 (.0010 ─ .0016) .0984 2.5 65 2600 .0016 (.0012 ─ .0020) .1260 3.2 60 2000 .0020 (.0016 ─ .0028) .1575 4.0 95 2400 .0028 (.0020 ─ .0031) .1969 5.0 95 1900 .0031 (.0024 ─ .0039) .2480 6.3 95 1500 .0035 (.0031 ─ .0043) .3150 8.0 120 1500 .0047 (.0039 ─ .0051) .3937 10.0 120 1300 .0059 (.0051 ─ .0067) .4724 12.0 120 1100 .0071 (.0059 ─ .0079) M126 DRILLING