Общий каталог Mitsubishi 2020 - 2021 - страница 1601

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

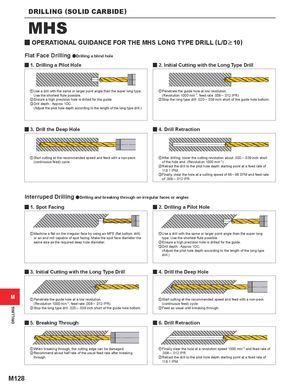

DRILLING (SOLID CARBIDE) MHS y OPERATIONAL GUIDANCE FOR THE MHS LONG TYPE DRILL (L/D > 10) Flat Face Drilling aDrilling a blind hole y 1. Drilling a Pilot Hole y 2. Initial Cutting with the Long Type Drill zUse a drill with the same or larger point angle than the super long type. zPenetrate the guide hole at low revolution. Use the shortest flute possible. (Revolution 1000 min-1, feed rate .008 ─ .012 IPR) xEnsure a high precision hole is drilled for the guide. xStop the long type drill .020 ─ .039 inch short of the guide hole bottom. cDrill depth : Approx 1DC. (Adjust the pilot hole depth according to the length of the long type drill.) y 3. Drill the Deep Hole y 4. Drill Retraction zStart cutting at the recommended speed and feed with a non-peck zAfter drilling, lower the cutting revolution about .020 ─ .039 inch short (continuous feed) cycle. of the hole end. (Revolution 1000 min-1) xRetract the drill to the pilot hole depth starting point at a feed rate of 118.1 IPM. cFinally, clear the hole at a cutting speed of 66 ─ 98 SFM and feed rate of .008 ─ .012 IPR. Interruped Drilling aDrilling and breaking through on irregular faces or angles y 1. Spot Facing y 2. Drilling a Pilot Hole zMachine a flat on the irregular face by using an MFE (flat bottom drill) zUse a drill with the same or larger point angle than the super long or an end mill capable of spot facing. Make the spot face diameter the type. Use the shortest flute possible. same size as the required deep hole diameter. xEnsure a high precision hole is drilled for the guide. cDrill depth : Approx 1DC. (Adjust the pilot hole depth according to the length of the long type drill.) y 3. Initial Cutting with the Long Type Drill y 4. Drill the Deep Hole M zPenetrate the guide hole at a low revolution. zStart cutting at the recommended speed and feed with a non-peck (Revolution 1000 min-1, feed rate .008 ─ .012 IPR) (continuous feed) cycle. xStop the long type drill .020 ─ .039 inch short of the guide hole bottom. xFeed as usual until breaking through. y 5. Breaking Through y 6. Drill Retraction zWhen breaking through, the cutting edge can be damaged. zFinally clear the hole at a revolution speed 1000 min-1 and feed rate of xRecommend about half rate of the usual feed rate after breaking .008 ─ .012 IPR. through. xRetract the drill to the pilot hole depth starting point at a feed rate of 118.1 IPM. M128 DRILLING