Общий каталог Mitsubishi 2020 - 2021 - страница 1581

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

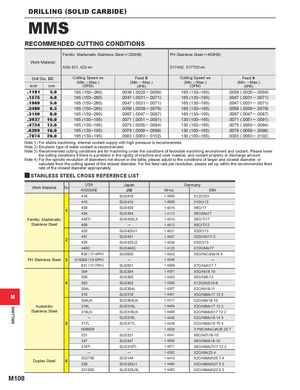

DRILLING (SOLID CARBIDE) MMS RECOMMENDED CUTTING CONDITIONS Ferritic, Martensitic Stainless Steel (>200HB) PH Stainless Steel (<450HB) Work Material AISI 431, 420 etc. S17400, S17700 etc. Drill Dia. DC Cutting Speed vc Feed fr Cutting Speed vc Feed fr (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) inch mm (SFM) (IPR) (SFM) (IPR) .1181 3.0 195 (150─260) .0039 (.0020 ─ .0059) 165 (130─195) .0039 (.0020 ─ .0059) .1575 4.0 195 (150─260) .0047 (.0031 ─ .0071) 165 (130─195) .0047 (.0031 ─ .0071) .1969 5.0 195 (150─260) .0047 (.0031 ─ .0071) 165 (130─195) .0047 (.0031 ─ .0071) .2480 6.3 195 (150─260) .0059 (.0039 ─ .0079) 165 (130─195) .0059 (.0039 ─ .0079) .3150 8.0 195 (150─260) .0067 (.0047 ─ .0087) 165 (130─195) .0067 (.0047 ─ .0087) .3937 10.0 165 (130─195) .0071 (.0051 ─ .0091) 130 (100─165) .0071 (.0051 ─ .0091) .4724 12.0 165 (130─195) .0075 (.0055 ─ .0094) 130 (100─165) .0075 (.0055 ─ .0094) .6299 16.0 165 (130─195) .0079 (.0059 ─ .0098) 130 (100─165) .0079 (.0059 ─ .0098) .7874 20.0 165 (130─195) .0083 (.0063 ─ .0102) 130 (100─165) .0083 (.0063 ─ .0102) Note 1) For stable machining, internal coolant supply with high pressure is recommended. Note 2) Emulsion type of water coolant is recommended. Note 3) Recommended cutting conditions are for machining under the conditions of favorable machining environment and coolant. Please lower the cutting conditions if there is a problem in the rigidity of machine and work material, and coolant property or discharge amount. Note 4) For the spindle revolution of diameters not shown in the table, please adjust to the conditions of larger and closest diameter, or calculate from the cutting speed of the closest diameter. For the feed rate per revolution, please set up within the recommended feed rate of the closest diameter appropriately. y STAINLESS STEEL CROSS REFERENCE LIST USAWork MaterialNoAISI/SAEJapanJIS GermanyW-no. DIN 416 SUS416 1.4005 X12CrS3 410 SUS410 1.4006 X10Cr13 430 SUS430 1.4016 X6Cr17 1 434 SUS434 1.4113 X6CrMo17 Ferritic, Martensitic 430Ti SUS430LX 1.4510 X6CrTi17 Stainless Steel 409 ─ 1.4512 X6CrTi12 420 SUS420J1 1.4021 X20Cr13 2 431420 SUS431 1.4057 X20CrNi17-2SUS420J21.4028X30Cr13 440C SUS440C 1.4125 X10CrMo17 630 (17-4PH) SUS630 1.4542 X5CrNiCuNb16 4 PH Stainless Steel 3 S15500 (15-5PH) ─ 1.4545 ─ 631 (17-7PH) SUS631 1.4568 X7CrNiAl17 7 304 SUS304 1.4301 X5CrNi18 10 305 SUS305 1.4303 X5CrNi8-12 4 303 SUS303 1.4305 X12CrNiS18-9 304L SUS304L 1.4307 X2CrNi19-11 M 316 SUS316 1.4401 X5CrNiMo17 12 2 304LN SUS304LN 1.4311 X2CrNiN18 10 Austenitic 316L SUS316L 1.4404 X2CrNiMo17 12 2 Stainless Steel 316LN SUS316LN 1.4406 X2CrNiMoN17 12 2 ─ SUS316L 1.4435 X2CrNiMo18 14 3 5 317L SUS317L 1.4438 X2CrNiMo18 15 4 N08926 ─ 1.4529 X1NiCrMoCuN25 20 7 321 SUS321 1.4541 X6CrNiTi18-10 347 SUS347 1.4550 X6CrNiNb18-10 316Ti SUS316Ti 1.4571 X6CrNiMoTi17 12 2 ─ ─ 1.4362 X2CrNiN23 4 Duplex Steel 6 S32750329 SCS14ASUS329J1 1.4410 X2CrNiMoN25 7 41.4460X3CrNiMoN27 5 2 S31803 SUS329J3L 1.4462 X2CrNiMoN22 5 3 M108 DRILLING