Общий каталог Mitsubishi 2020 - 2021 - страница 1580

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

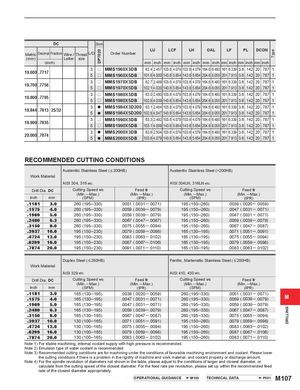

DP7020 Type DRILLING DC Stock LU LCF LH OAL LF PL DCON Metric Decimal Fraction Wire / Thread L/D Order Number (mm) Letter size (inch) mm inch mm inch mm inch mm inch mm inch mm inch mm inch 19.600 .7717 3 r MMS1960X3DB 62.4 2.457 103.6 4.079 103.6 4.079 164.6 6.480 161 6.339 3.6 .142 20 .787 15rMMS1960X5DB101.6 4.000 143.6 5.654 143.6 5.654 204.6 8.055 201 7.9133.6 .14220.7871 19.700 .7756 3 r MMS1970X3DB 62.7 2.469 103.6 4.079 103.6 4.079 164.6 6.480 161 6.339 3.6 .142 20 .787 15rMMS1970X5DB102.1 4.020 143.6 5.654 143.6 5.654 204.6 8.055 201 7.9133.6 .14220.7871 19.800 .7795 3 r MMS1980X3DB 63.0 2.480 103.6 4.079 103.6 4.079 164.6 6.480 161 6.339 3.6 .142 20 .787 15rMMS1980X5DB102.6 4.039 143.6 5.654 143.6 5.654 204.6 8.055 201 7.9133.6 .14220.7871 19.844 .7813 25/32 3 a MMS1984X3D200 63.1 2.484 103.6 4.079 103.6 4.079 164.6 6.480 161 6.339 3.6 .142 20 .787 15aMMS1984X5D200102.8 4.047 143.6 5.654143.6 5.654204.6 8.055201 7.9133.6.14220.7871 19.900 .7835 3 r MMS1990X3DB 63.3 2.492 103.6 4.079 103.6 4.079 164.6 6.480 161 6.339 3.6 .142 20 .787 15rMMS1990X5DB103.1 4.059 143.6 5.654 143.6 5.654 204.6 8.055 201 7.9133.6 .14220.7871 20.000 .7874 3 a MMS2000X3DB 63.6 2.504 103.6 4.079 103.6 4.079 164.6 6.480 161 6.339 3.6 .142 20 .787 15aMMS2000X5DB103.6 4.079 143.6 5.654 143.6 5.654 204.6 8.055 201 7.9133.6 .14220.7871 RECOMMENDED CUTTING CONDITIONS Austenitic Stainless Steel ( < 200HB) Austenitic Stainless Steel (>200HB) Work Material AISI 304, 316 etc. AISI 304LN, 316LN etc. Drill Dia. DC Cutting Speed vc Feed fr Cutting Speed vc Feed fr (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) inch mm (SFM) (IPR) (SFM) (IPR) .1181 3.0 260 (195─330) .0051 (.0031 ─ .0071) 195 (150─260) .0039 (.0020 ─ .0059) .1575 4.0 260 (195─330) .0059 (.0039 ─ .0079) 195 (150─260) .0047 (.0031 ─ .0071) .1969 5.0 260 (195─330) .0059 (.0039 ─ .0079) 195 (150─260) .0047 (.0031 ─ .0071) .2480 6.3 260 (195─330) .0067 (.0047 ─ .0087) 195 (150─260) .0059 (.0039 ─ .0079) .3150 8.0 260 (195─330) .0075 (.0055 ─ .0094) 195 (150─260) .0067 (.0047 ─ .0087) .3937 10.0 195 (150─230) .0079 (.0059 ─ .0098) 165 (130─195) .0071 (.0051 ─ .0091) .4724 12.0 195 (150─230) .0083 (.0063 ─ .0102) 165 (130─195) .0075 (.0055 ─ .0094) .6299 16.0 195 (150─230) .0087 (.0067 ─ .0106) 165 (130─195) .0079 (.0059 ─ .0098) .7874 20.0 195 (150─230) .0091 (.0071 ─ .0110) 165 (130─195) .0083 (.0063 ─ .0102) Duplex Steel ( < 280HB) Ferritic, Martensitic Stainless Steel ( < 200HB) Work Material AISI 329 etc. AISI 410, 430 etc. Drill Dia. DC Cutting Speed vc Feed fr Cutting Speed vc Feed fr (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) inch mm (SFM) (IPR) (SFM) (IPR) .1181 3.0 165 (130─195) .0039 (.0020 ─ .0059).15754.0165 (130─195).0047 (.0031 ─ .0071)260 (195─330)260 (195─330).0051 (.0031 ─ .0071).0059 (.0039 ─ .0079)M .1969 5.0 165 (130─195) .0047 (.0031 ─ .0071) 260 (195─330) .0059 (.0039 ─ .0079) .2480 6.3 165 (130─195) .0059 (.0039 ─ .0079) 260 (195─330) .0067 (.0047 ─ .0087) .3150 8.0 165 (130─195) .0067 (.0047 ─ .0087) 260 (195─330) .0075 (.0055 ─ .0094) .3937 10.0 130 (100─165) .0071 (.0051 ─ .0091) 195 (150─260) .0079 (.0059 ─ .0098) .4724 12.0 130 (100─165) .0075 (.0055 ─ .0094) 195 (150─260) .0083 (.0063 ─ .0102) .6299 16.0 130 (100─165) .0079 (.0059 ─ .0098) 195 (150─260) .0087 (.0067 ─ .0106) .7874 20.0 130 (100─165) .0083 (.0063 ─ .0102) 195 (150─260) .0083 (.0071 ─ .0110) Note 1) For stable machining, internal coolant supply with high pressure is recommended. Note 2) Emulsion type of water coolant is recommended. Note 3) Recommended cutting conditions are for machining under the conditions of favorable machining environment and coolant. Please lower the cutting conditions if there is a problem in the rigidity of machine and work material, and coolant property or discharge amount. Note 4) For the spindle revolution of diameters not shown in the table, please adjust to the conditions of larger and closest diameter, or calculate from the cutting speed of the closest diameter. For the feed rate per revolution, please set up within the recommended feed rate of the closest diameter appropriately. OPERATIONAL GUIDANCE M109 TECHNICAL DATA P001 M107