Каталог Sumitomo микроинструмент - страница 11

Навигация

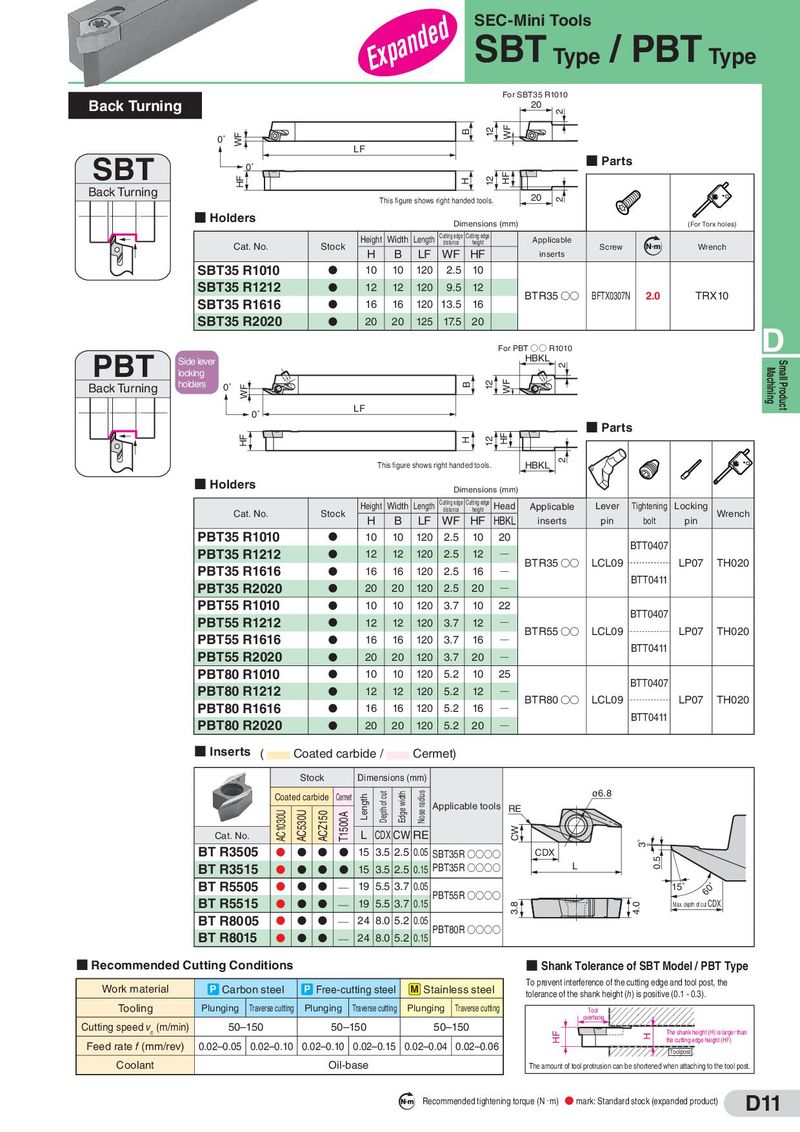

Expanded SEC-Mini Tools SBT Type / PBT Type For SBT35 R1010 Back Turning 20 2 WF B 12 WF 0˚ LF SBT 0˚ ■ Parts HF H 12 HF Back Turning This figure shows right handed tools. 20 2 ■ Holders Dimensions (mm) (For Torx holes) Height Width Length Cutting edge Cutting edge Applicable Cat. No. Stock distance height Screw Nm Wrench H B LF WF HF inserts SBT35 R1010 D 10 10 120 2.5 10 SBT35 R1212 D 12 12 120 9.5 12 BTR35 ○○ BFTX0307N 2.0 TRX10 SBT35 R1616 D 16 16 120 13.5 16 SBT35 R2020 D 20 20 125 17.5 20 For PBT ○○ R1010 D PBT Side lever HBKL 2 Small Product locking Machining Back Turning holders 0˚ WF B 12 WF 0˚ LF HF ■ Parts HF H 12 This figure shows right handed tools. HBKL 2 ■ Holders Dimensions (mm) Height Width Length Cutting edge Cutting edge Head Applicable Lever Tightening Locking Cat. No. Stock distance height Wrench H B LF WF HF HBKL inserts pin bolt pin PBT35 R1010 D 10 10 120 2.5 10 20 BTT0407 PBT35 R1212 D 12 12 120 2.5 12 Q BTR35 ○○ LCL09 LP07 TH020 PBT35 R1616 D 16 16 120 2.5 16 Q BTT0411 PBT35 R2020 D 20 20 120 2.5 20 Q PBT55 R1010 D 10 10 120 3.7 10 22 BTT0407 PBT55 R1212 D 12 12 120 3.7 12 Q BTR55 ○○ LCL09 LP07 TH020 PBT55 R1616 D 16 16 120 3.7 16 Q BTT0411 PBT55 R2020 D 20 20 120 3.7 20 Q PBT80 R1010 D 10 10 120 5.2 10 25 BTT0407 PBT80 R1212 D 12 12 120 5.2 12 Q BTR80 ○○ LCL09 LP07 TH020 PBT80 R1616 D 16 16 120 5.2 16 Q BTT0411 PBT80 R2020 D 20 20 120 5.2 20 Q ■ Inserts ( Coated carbide / Cermet) Stock Dimensions (mm) Coated carbide Cermet Length Depth of cut Edge width Nose radius ø6.8 AC1030U AC530U ACZ150 Applicable tools RE Cat. No. T1500A L CDX CW RE CW 3° BT R3505 D D D D 15 3.5 2.5 0.05 SBT35R ○○○○ CDX 0.5 BT R3515 D D D D 15 3.5 2.5 0.15 PBT35R ○○○○ L BT R5505 D D D ̶ 19 5.5 3.7 0.05 PBT55R ○○○○ 15° 60° BT R5515 D D D ̶ 19 5.5 3.7 0.15 3.8 4.0 Max. depth of cut CDX BT R8005 D D D ̶ 24 8.0 5.2 0.05 PBT80R ○○○○ BT R8015 D D D ̶ 24 8.0 5.2 0.15 ■ Recommended Cutting Conditions ■ Shank Tolerance of SBT Model / PBT Type Work material P Carbon steel P Free-cutting steel M Stainless steel To prevent interference of the cutting edge and tool post, the tolerance of the shank height (h) is positive (0.1 - 0.3). Tooling Plunging Traverse cutting Plunging Traverse cutting Plunging Traverse cutting Tool overhang Cutting speed vc (m/min) 50–150 50–150 50–150 The shank height (H) is larger than HF H the cutting edge height (HF) Feed rate f (mm/rev) 0.02–0.05 0.02–0.10 0.02–0.10 0.02–0.15 0.02–0.04 0.02–0.06 Toolpost Coolant Oil-base The amount of tool protrusion can be shortened when attaching to the tool post. Recommended tightening torque (N・m) ● mark: Standard stock (expanded product) D11

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки