Каталог Sumitomo микроинструмент - страница 10

Навигация

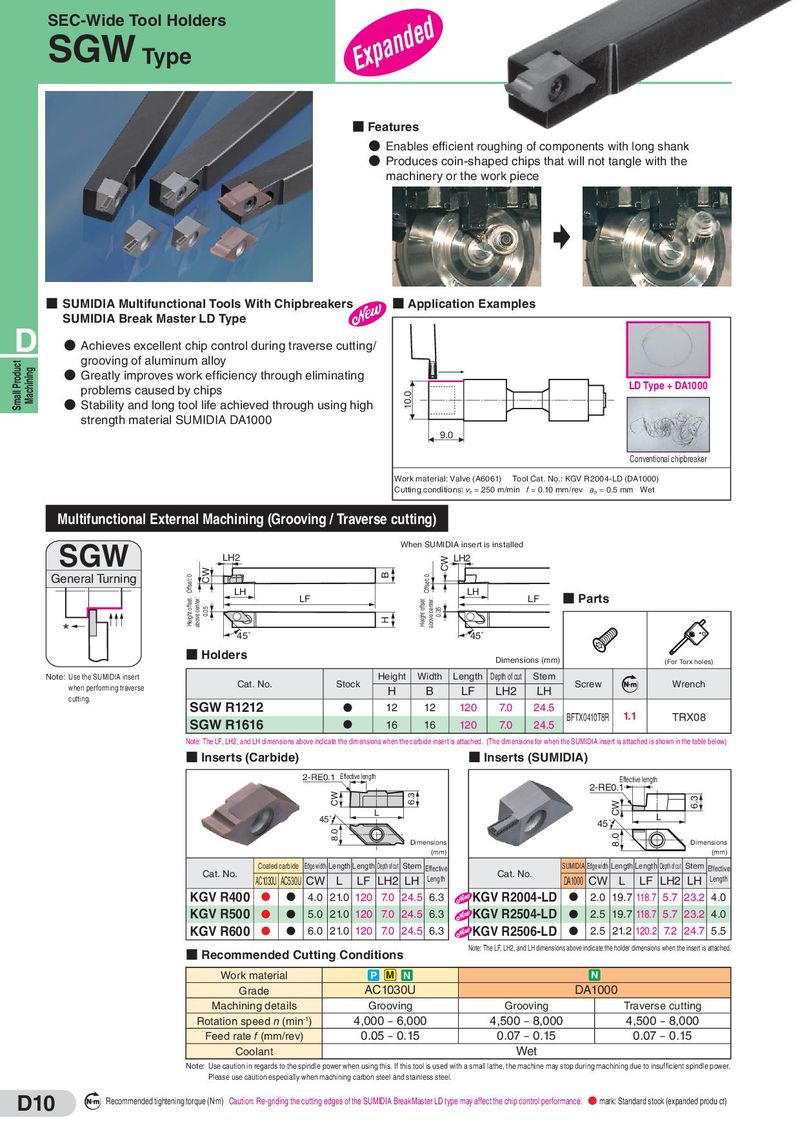

SEC-Wide Tool Holders Expanded SGW Type ■ Features ● Enables efficient roughing of components with long shank ● Produces coin-shaped chips that will not tangle with the machinery or the work piece ■ SUMIDIA Multifunctional Tools With Chipbreakers ■ Application Examples SUMIDIA Break Master LD Type D ● Achieves excellent chip control during traverse cutting/ Small Product grooving of aluminum alloy Machining ● Greatly improves work efficiency through eliminating LD Type + DA1000 problems caused by chips 10.0 ● Stability and long tool life achieved through using high strength material SUMIDIA DA1000 9.0 Conventional chipbreaker Work material: Valve (A6061) Tool Cat. No.: KGV R2004-LD (DA1000) Cutting conditions: vc = 250 m/min f = 0.10 mm/rev ap = 0.5 mm Wet Multifunctional External Machining (Grooving / Traverse cutting) SGW When SUMIDIA insert is installed LH2 CW LH2 General Turning Offset: 0 CW B Offset: 0 LH LF LH LF ■ Parts Height offset above center: 0.05 Height offset above center: 0.35 * H 45˚ 45˚ ■ Holders Dimensions (mm) (For Torx holes) Note: Use the SUMIDIA insert Cat. No. Stock Height Width Length Depth of cut Stem Screw Wrench when performing traverse H B LF LH2 LH cutting. SGW R1212 D 12 12 120 7.0 24.5 1.1 SGW R1616 D 16 16 120 7.0 24.5 BFTX0410T8R TRX08 Note: The LF, LH2, and LH dimensions above indicate the dimensions when the carbide insert is attached. (The dimensions for when the SUMIDIA insert is attached is shown in the table below) ■ Inserts (Carbide) ■ Inserts (SUMIDIA) 2-RE0.1 Effective length Effective length CW 2-RE0.1 6.3 CW 6.3 45˚ L L 45˚ 8.0 Dimensions 8.0 Dimensions (mm) (mm) Cat. No. Coated carbide Edge width Length Length Depth of cut Stem Effective Cat. No. SUMIDIA Edge width Length Length Depth of cut Stem Effective AC1030U AC530U CW L LF LH2 LH Length DA1000 CW L LF LH2 LH Length KGV R400 D D 4.0 21.0 120 7.0 24.5 6.3 KGV R2004-LD D 2.0 19.7 118.7 5.7 23.2 4.0 KGV R500 D D 5.0 21.0 120 7.0 24.5 6.3 KGV R2504-LD D 2.5 19.7 118.7 5.7 23.2 4.0 KGV R600 D D 6.0 21.0 120 7.0 24.5 6.3 KGV R2506-LD D 2.5 21.2 120.2 7.2 24.7 5.5 ■ Recommended Cutting Conditions Note: The LF, LH2, and LH dimensions above indicate the holder dimensions when the insert is attached. Work material P M N N Grade AC1030U DA1000 Machining details Grooving Grooving Traverse cutting Rotation speed n (min-1) 4,000 ‒ 6,000 4,500 ‒ 8,000 4,500 ‒ 8,000 Feed rate f (mm/rev) 0.05 ‒ 0.15 0.07 ‒ 0.15 0.07 ‒ 0.15 Coolant Wet Note: Use caution in regards to the spindle power when using this. If this tool is used with a small lathe, the machine may stop during machining due to insufficient spindle power. Please use caution especially when machining carbon steel and stainless steel. D10 Recommended tightening torque (N・m) Caution: Re-griding the cutting edges of the SUMIDIA BreakMaster LD type may affect the chip control performance. ● mark: Standard stock (expanded produ ct)

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки