Общий каталог Mitsubishi 2020 - 2021 - страница 976

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

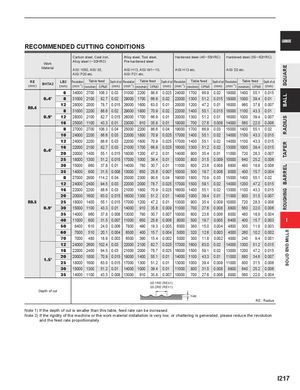

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS CARBIDE RECOMMENDED CUTTING CONDITIONS Carbon steel, Cast iron, Alloy steel, Tool steel, Hardened steel (45 ─55HRC) Hardened steel (55 ─62HRC) Work Alloy steel (─ 30HRC) Pre-hardened steel Material AISI 1050, AISI 35, AISI H13, AISI W1─10, AISI H13 etc. AISI D2 etc. AISI P20 etc. AISI P21 etc. RE(mm) BHTA2 LB2 Revolution Table feed Depth of cut Revolution Table feed Depth of cut Revolution Table feed Depth of cut Revolution Table feed Depth of cut(mm)(min-1)(mm/min)(IPM)(mm)(min-1)(mm/min)(IPM)(mm)(min-1)(mm/min)(IPM)(mm)(min-1)(mm/min)(IPM)(mm) 6 34000 2700 106.3 0.03 31000 2200 86.6 0.025 24000 1700 66.9 0.02 19000 1400 55.1 0.015 0.4° 8 31000 2100 82.7 0.02 29000 1700 66.9 0.02 22000 1300 51.2 0.015 18000 1000 39.4 0.01 R0.4 12 28000 2000 78.7 0.015 26000 1600 63.0 0.01 20000 1200 47.2 0.01 16000 960 37.8 0.007831000220086.60.0229000180070.90.0222000140055.10.01518000110043.30.01 0.9° 12 28000 2100 82.7 0.015 26000 1700 66.9 0.01 20000 1300 51.2 0.01 16000 1000 39.4 0.007 16 25000 1100 43.3 0.01 23000 910 35.8 0.01 18000 700 27.6 0.008 14000 560 22.0 0.006 8 27000 2700 106.3 0.04 25000 2200 86.6 0.04 19000 1700 66.9 0.03 15000 1400 55.1 0.02 10 24000 2200 86.6 0.03 22000 1800 70.9 0.025 17000 1400 55.1 0.02 14000 1100 43.3 0.015 12 24000 2200 86.6 0.03 22000 1800 70.9 0.025 17000 1400 55.1 0.02 14000 1100 43.3 0.015 0.4° 16 22000 2100 82.7 0.03 21000 1700 66.9 0.025 16000 1300 51.2 0.02 13000 1000 39.4 0.0152020000140055.10.01518000120047.20.011400090035.40.011100072028.30.007 25 18000 1300 51.2 0.015 17000 1000 39.4 0.01 13000 800 31.5 0.009 10000 640 25.2 0.006 30 15000 960 37.8 0.01 14000 780 30.7 0.01 11000 600 23.6 0.008 8800 480 18.9 0.006 35 14000 800 31.5 0.008 13000 650 25.6 0.007 10000 500 19.7 0.006 8000 400 15.7 0.004 8 27000 2900 114.2 0.04 25000 2300 90.6 0.04 19000 1800 70.9 0.03 15000 1400 55.1 0.02 12 24000 2400 94.5 0.03 22000 2000 78.7 0.025 17000 1500 59.1 0.02 14000 1200 47.2 0.015 16 22000 2200 86.6 0.03 21000 1800 70.9 0.025 16000 1400 55.1 0.02 13000 1100 43.3 0.015 20 20000 1600 63.0 0.015 18000 1300 51.2 0.01 14000 1000 39.4 0.01 11000 800 31.5 0.007 R0.5 25 18000 1400 55.1 0.015 17000 1200 47.2 0.01 13000 900 35.4 0.009 10000 720 28.3 0.006 0.9° 30 15000 1100 43.3 0.01 14000 910 35.8 0.009 11000 700 27.6 0.008 8800 560 22.0 0.006 35 14000 960 37.8 0.008 13000 780 30.7 0.007 10000 600 23.6 0.006 8000 480 18.9 0.004 40 11000 800 31.5 0.007 11000 650 25.6 0.006 8000 500 19.7 0.005 6400 400 15.7 0.003 I 50 8400 610 24.0 0.006 7800 490 19.3 0.005 6000 380 15.0 0.004 4800 300 11.8 0.003 60 7000 510 20.1 0.004 6500 400 15.7 0.004 5000 320 12.6 0.003 4000 260 10.2 0.002 70 7000 480 18.9 0.003 6500 390 15.4 0.002 5000 300 11.8 0.002 4000 240 9.4 0.001 12 24000 2600 102.4 0.03 22000 2100 82.7 0.025 17000 1600 63.0 0.02 14000 1300 51.2 0.015 16 22000 2400 94.5 0.03 21000 2000 78.7 0.025 16000 1500 59.1 0.02 13000 1200 47.2 0.015 1.5° 20 20000 1800 70.9 0.015 18000 1400 55.1 0.01 14000 1100 43.3 0.01 11000 880 34.6 0.0072518000160063.00.01517000130051.20.0113000100039.40.0091100080031.50.006 30 15000 1300 51.2 0.01 14000 1000 39.4 0.01 11000 800 31.5 0.008 8800 640 25.2 0.006 35 14000 1100 43.3 0.008 13000 910 35.8 0.007 10000 700 27.6 0.006 8000 560 22.0 0.004 <0.1RE (RE<1) <0.2RE (RE>1) Depth of cut < ap RE : Radius Note 1) If the depth of cut is smaller than this table, feed rate can be increased. Note 2) If the rigidity of the machine or the work material installation is very low, or chattering is generated, please reduce the revolution and the feed rate proportionately. I217