Общий каталог Mitsubishi 2020 - 2021 - страница 869

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

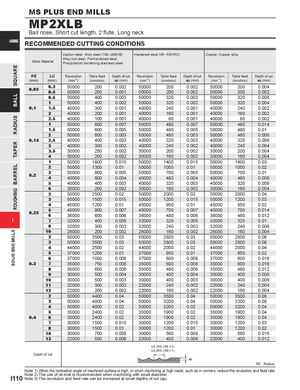

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS MS PLUS END MILLS MP2XLB Ball nose, Short cut length, 2 flute, Long neck CARBIDE RECOMMENDED CUTTING CONDITIONS Carbon steel, Alloy steel (180─280HB) Hardened steel (45─55HRC) Copper, Copper alloy Work Material Alloy tool steel, Pre-hardened steel,Precipitation hardening stainless steel RE LU Revolution Table feed Depth of cut Revolution Table feed Depth of cut Revolution Table feed Depth of cut (mm) (mm) (min-1) (mm/min) ap (mm) (min-1) (mm/min) ap (mm) (min-1) (mm/min) ap (mm) 0.05 0.30.5 5000050000 200 0.002 500002000.00150000200 0.002 500002000.00250000200 0.0042000.002 0.5 50000 400 0.003 50000 320 0.003 50000 320 0.006 1 50000 400 0.002 50000 320 0.002 50000 320 0.004 0.1 1.5 40000 300 0.001 40000 240 0.001 40000 240 0.002 2 40000 200 0.001 40000 160 0.001 40000 160 0.002 2.5 40000 100 0.001 40000 80 0.001 40000 80 0.002 1 50000 600 0.007 50000 480 0.007 50000 480 0.014 1.5 50000 600 0.005 50000 480 0.005 50000 480 0.01 2 50000 600 0.003 50000 480 0.003 50000 480 0.006 0.15 2.5 40000 400 0.003 40000 320 0.003 40000 320 0.006 3 40000 300 0.002 40000 240 0.002 40000 240 0.004 3.5 30000 250 0.002 30000 200 0.002 30000 200 0.004 4 30000 200 0.002 30000 160 0.002 30000 160 0.004 1 50000 1800 0.015 50000 1400 0.015 50000 1400 0.03 2 50000 1300 0.01 50000 1000 0.01 50000 1000 0.02 0.2 34 50000 900 0.005 50000 700 0.005 50000 700 0.01400006000.004400004800.004400004800.008 5 40000 400 0.003 40000 320 0.003 40000 320 0.006 6 30000 200 0.002 30000 160 0.002 30000 160 0.004 2 50000 2500 0.02 50000 2000 0.02 50000 2000 0.04 3 50000 1500 0.015 50000 1200 0.015 50000 1200 0.03 4 45000 1200 0.01 45000 950 0.01 45000 950 0.02 0.25 56 45000 900 0.007 45000 700 0.007 45000 700 0.014360006000.006360004800.006360004800.012 I 7 32000 400 0.005 32000 320 0.005 32000 320 0.01 8 32000 300 0.003 32000 240 0.003 32000 240 0.006 10 26000 200 0.002 26000 160 0.002 26000 160 0.004 2 50000 3500 0.03 50000 2800 0.03 50000 2800 0.06 3 50000 3500 0.03 50000 2800 0.03 50000 2800 0.06 4 44000 2500 0.02 44000 2000 0.02 44000 2000 0.04 5 37000 1200 0.01 37000 950 0.01 37000 950 0.02 6 37000 1000 0.008 37000 800 0.008 37000 800 0.016 0.3 7 35000 750 0.008 35000 600 0.008 35000 600 0.016 8 35000 600 0.006 35000 480 0.006 35000 480 0.012 9 30000 500 0.004 30000 400 0.004 30000 400 0.008 10 30000 500 0.003 30000 400 0.003 30000 400 0.006 11 22000 300 0.002 22000 240 0.002 22000 240 0.004 12 22000 200 0.002 22000 160 0.002 22000 160 0.004 2 50000 4400 0.04 50000 3500 0.04 50000 3500 0.08 3 50000 4000 0.04 50000 3200 0.04 50000 3200 0.08 4 50000 4000 0.02 50000 3200 0.02 50000 3200 0.04 5 35000 2400 0.02 35000 1900 0.02 35000 1900 0.04 0.4 6 35000 2400 0.02 35000 1900 0.02 35000 1900 0.04 7 30000 1500 0.015 30000 1200 0.015 30000 1200 0.03 8 30000 1500 0.01 30000 1200 0.01 30000 1200 0.02 10 30000 700 0.008 30000 560 0.008 30000 560 0.016 12 22000 500 0.006 22000 400 0.006 22000 400 0.012 <0.1RE (RE <1) <0.2RE (RE> 1) Depth of cut ap RE : Radius Note 1) When the inclination angle of machined surface is high, or when machining at high loads; such as in corners, reduce the revolution and feed rate. I110 Note 2) The use of oil mist is recommended when machining with small diameter.Note 3) The revolution and feed rate can be increased at small depths of cut (ap).