Общий каталог Mitsubishi 2020 - 2021 - страница 1546

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

Adjusting Screw

A

DCx1

DRILLING

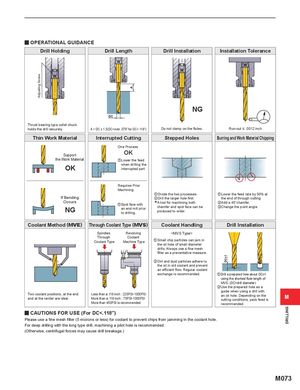

y OPERATIONAL GUIDANCE

Drill Holding Drill Length Drill Installation Installation Tolerance

NG

DC

Thrust bearing type collet chuck

holds the drill securely. A > DC x 1.5(DC×over .079" for DC<.118") Do not clamp on the flutes. Run-out < .0012 inch

Thin Work Material Interrupted Cutting Stepped Holes Burring and Work Material Chipping

One Process

Support OK

the Work Material zLower the feed

OK when drilling theinterrupted part.

Requires Prior

Machining

zDivide the two processes. zLower the feed rate by 50% at

If Bending xDrill the larger hole first. the end of through cutting.

OccursNG zSpot face withan end mill priorto drilling.*A tool for machining both chamfer and spot face can beproduced to order.xAdd a 45°chamfer.cChange the point angle.

Coolant Method (MVE) Through Coolant Type (MVS) Coolant Handling Drill Installation

Spindles Revolving