Общий каталог Mitsubishi 2020 - 2021 - страница 1693

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

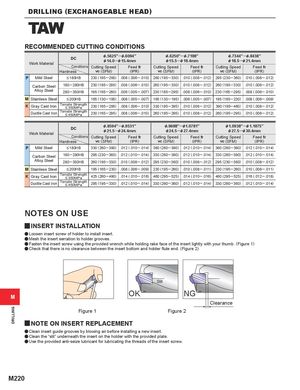

DRILLING (EXCHANGEABLE HEAD) TAW RECOMMENDED CUTTING CONDITIONS DCWork Material &.5625" ─ &.6094"& 14.0─ & 15.4mm &.6250" ─ &.7188"& 15.5 ─ & 18.4mm &.7344" ─ &.8438"& 18.5 ─ & 21.4mm Conditions Cutting Speed Feed fr Cutting Speed Feed fr Cutting Speed Feed fr Hardness vc (SFM) (IPR) vc (SFM) (IPR) vc (SFM) (IPR) P Mild Steel < 180HB 230 (195 ─295) .008 (.006─.010) 260 (195─330) .010 (.008─ .012) 295 (230─ 360) .010 (.008 ─ .012) Carbon Steel 180 ─280HB 230 (195 ─295) .008 (.006─.010) 260 (195─330) .010 (.008─.012) 260 (195─330) .010 (.008 ─ .012) Alloy Steel 280 ─350HB 195 (165 ─260) .006 (.005─ .007) 230 (165─295) .008 (.006─ .010) 230 (165─295) .008 (.006─ .010) M Stainless Steel < 200HB 165 (130 ─195) .006 (.005─.007) 165 (130─195) .006 (.005─ .007) 195 (165─ 230) .008 (.006 ─ .009) K Gray Cast Iron Tensile Strength< 350MPa230 (165 ─295).008 (.006─.010)330 (195─395) .010 (.008─ .012) 390 (195─ 460) .010 (.008 ─ .012) Ductile Cast Iron Tensile Strength< 450MPa230 (165 ─295).008 (.006─.010)260 (195─295) .010 (.008─ .012) 260 (195 ─295) .010 (.008 ─.012) DCWork Material &.8594" ─ &.9531"& 21.5─ & 24.4mm &.9688" ─ &1.0781" & 1.0938" ─ & 1.1875"& 24.5 ─ & 27.4mm& 27.5 ─ & 30.4mm Conditions Cutting Speed Feed fr Cutting Speed Feed fr Cutting Speed Feed fr Hardness vc (SFM) (IPR) vc (SFM) (IPR) vc (SFM) (IPR) P Mild Steel < 180HB 330 (260 ─390) .012 (.010─.014) 360 (260─390) .012 (.010─ .014) 360 (260─ 390) .012 (.010 ─ .014) Carbon Steel 180 ─280HB 295 (230 ─360) .012 (.010─.014) 330 (260─390) .012 (.010─.014) 330 (260─390) .012 (.010 ─ .014) Alloy Steel 280 ─350HB 260 (195 ─330) .010 (.008─ .012) 295 (230─360) .010 (.008─ .012) 295 (230─360) .010 (.008─ .012) M Stainless Steel < 200HB 195 (165 ─230) .008 (.006─.009) 230 (195─260) .010 (.008─ .011) 230 (195─ 260) .010 (.008 ─ .011) K Gray Cast Iron Tensile Strength< 350MPa425 (260 ─490).014 (.010─.016)460 (295─525) .014 (.010─ .016) 460 (295 ─525) .016 (.012 ─.018) Ductile Cast Iron Tensile Strength< 450MPa295 (195 ─330).012 (.010─.014)330 (260─360) .012 (.010─ .014) 330 (260 ─360) .012 (.010 ─.014) NOTES ON USE y INSERT INSTALLATION a Loosen insert screw of holder to install insert. a Mesh the insert serration to holder grooves. a Fasten the insert screw using the provided wrench while holding rake face of the insert lightly with your thumb. (Figure 1) a Check that there is no clearance between the insert bottom and holder flute end. (Figure 2) Slit M OK NG Clearance Figure 1 Figure 2 y NOTE ON INSERT REPLACEMENT a Clean insert guide grooves by blowing air before installing a new insert. a Clean the “slit” underneath the insert on the holder with the provided plate. a Use the provided anti-seize lubricant for lubricating the threads of the insert screw. M220 DRILLING