Общий каталог Mitsubishi 2020 - 2021 - страница 1642

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

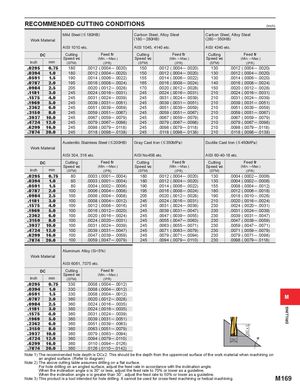

RECOMMENDED CUTTING CONDITIONS (inch) Mild Steel ( < 180HB) Carbon Steel, Alloy Steel Carbon Steel, Alloy Steel Work Material (180 ─ 280HB) (280 ─ 350HB) AISI 1010 etc. AISI 1045, 4140 etc. AISI 4340 etc. DC Cutting Feed fr Cutting Feed fr Cutting Feed fr Speed vc (Min. ─ Max.) Speed vc (Min. ─ Max.) Speed vc (Min. ─ Max.) inch mm (SFM) (IPR) (SFM) (IPR) (SFM) (IPR) .0295 0.75 180 .0012 (.0004 ─ .0020) 150 .0012 (.0004 ─ .0020) 130 .0012 (.0004 ─ .0020) .0394 1.0 180 .0012 (.0004 ─ .0020) 150 .0012 (.0004 ─ .0020) 130 .0012 (.0004 ─ .0020) .0591 1.5 190 .0014 (.0006 ─ .0022) 155 .0014 (.0006 ─ .0022) 130 .0014 (.0006 ─ .0020) .0787 2.0 195 .0016 (.0008 ─ .0024) 165 .0016 (.0008 ─ .0024) 140 .0016 (.0008 ─ .0024) .0984 2.5 205 .0020 (.0012 ─ .0028) 170 .0020 (.0012 ─ .0028) 150 .0020 (.0012 ─ .0028) .1181 3.0 245 .0024 (.0016 ─ .0031) 245 .0024 (.0016 ─ .0031) 210 .0024 (.0016 ─ .0031) .1575 4.0 245 .0031 (.0024 ─ .0039) 245 .0031 (.0024 ─ .0039) 210 .0031 (.0024 ─ .0039) .1969 5.0 245 .0039 (.0031 ─ .0051) 245 .0039 (.0031 ─ .0051) 210 .0039 (.0031 ─ .0051) .2362 6.0 245 .0051 (.0039 ─ .0059) 245 .0051 (.0039 ─ .0059) 210 .0051 (.0039 ─ .0059) .3150 8.0 245 .0059 (.0051 ─ .0067) 245 .0059 (.0051 ─ .0067) 210 .0059 (.0051 ─ .0067) .3937 10.0 245 .0067 (.0059 ─ .0079) 245 .0067 (.0059 ─ .0079) 210 .0067 (.0059 ─ .0079) .4724 12.0 245 .0079 (.0067 ─ .0098) 245 .0079 (.0067 ─ .0098) 210 .0079 (.0067 ─ .0098) .6299 16.0 245 .0098 (.0079 ─ .0118) 245 .0098 (.0079 ─ .0118) 210 .0098 (.0079 ─ .0118) .7874 20.0 245 .0118 (.0098 ─ .0138) 245 .0118 (.0098 ─ .0138) 210 .0118 (.0098 ─ .0138) Austenitic Stainless Steel ( < 200HB) Gray Cast Iron ( < 350MPa) Ductile Cast Iron ( < 450MPa) Work Material AISI 304, 316 etc. AISI No45B etc. AISI 60-40-18 etc. DC Cutting Feed fr Cutting Feed fr Cutting Feed fr Speed vc (Min. ─ Max.) Speed vc (Min. ─ Max.) Speed vc (Min. ─ Max.) inch mm (SFM) (IPR) (SFM) (IPR) (SFM) (IPR) .0295 0.75 80 .0003 (.0001 ─ .0004) 180 .0012 (.0004 ─ .0020) 130 .0004 (.0002 ─ .0006) .0394 1.0 80 .0003 (.0001 ─ .0004) 180 .0012 (.0004 ─ .0020) 130 .0004 (.0002 ─ .0006) .0591 1.5 80 .0004 (.0002 ─ .0006) 190 .0014 (.0006 ─ .0022) 155 .0008 (.0004 ─ .0012) .0787 2.0 100 .0006 (.0004 ─ .0008) 195 .0016 (.0008 ─ .0024) 180 .0012 (.0006 ─ .0018) .0984 2.5 100 .0006 (.0004 ─ .0008) 205 .0020 (.0012 ─ .0028) 190 .0018 (.0010 ─ .0026) .1181 3.0 100 .0008 (.0004 ─ .0012) 245 .0024 (.0016 ─ .0031) 210 .0020 (.0016 ─ .0024) .1575 4.0 100 .0012 (.0008 ─ .0016) 245 .0031 (.0024 ─ .0039) 230 .0024 (.0020 ─ .0031) .1969 5.0 100 .0016 (.0012 ─ .0020) 245 .0039 (.0031 ─ .0047) 230 .0031 (.0024 ─ .0039) .2362 6.0 100 .0020 (.0016 ─ .0024) 245 .0047 (.0039 ─ .0055) 230 .0039 (.0031 ─ .0047) .3150 8.0 100 .0024 (.0020 ─ .0031) 245 .0055 (.0047 ─ .0063) 230 .0047 (.0039 ─ .0059) .3937 10.0 100 .0031 (.0024 ─ .0039) 245 .0063 (.0055 ─ .0071) 230 .0059 (.0047 ─ .0071) .4724 12.0 100 .0039 (.0031 ─ .0047) 245 .0071 (.0063 ─ .0079) 230 .0071 (.0059 ─ .0079) .6299 16.0 100 .0047 (.0039 ─ .0059) 245 .0079 (.0071 ─ .0094) 230 .0079 (.0071 ─ .0098) .7874 20.0 100 .0059 (.0047 ─ .0079) 245 .0094 (.0079 ─ .0110) 230 .0098 (.0079 ─ .0118) Aluminum Alloy (Si<5%) Work Material AISI 6061, 7075 etc. DC Cutting Feed fr Speed vc (Min. ─ Max.) inch mm (SFM) (IPR) .0295 0.75 330 .0008 (.0004 ─ .0012) .0394 1.0 330 .0008 (.0004 ─ .0012) .0591 1.5 330 .0008 (.0004 ─ .0012).07872.0360.0020 (.0012 ─ .0028) M .0984 2.5 360 .0024 (.0016 ─ .0035) .1181 3.0 360 .0024 (.0016 ─ .0035) .1575 4.0 360 .0031 (.0024 ─ .0039) .1969 5.0 360 .0039 (.0031 ─ .0051) .2362 6.0 360 .0051 (.0039 ─ .0063) .3150 8.0 360 .0063 (.0051 ─ .0079) .3937 10.0 360 .0079 (.0063 ─ .0094) .4724 12.0 360 .0094 (.0079 ─ .0110) DC α .6299 16.0 360 .0110 (.0094 ─ .0126) .7874 20.0 360 .0126 (.0110 ─ .0142) Note 1) The recommended hole depth is DCx2. This should be the depth from the uppermost surface of the work material when machining on an angled surface. (Refer to diagram) Note 2) The above cutting table assumes drilling on a flat surface. For hole drilling on an angled surface, adjust the feed rate in accordance with the inclination angle. When the inclination angle α is 30° or less, adjust the feed rate to 70% or lower as a guideline. When the inclination angle α is greater than 30°, adjust the feed rate to 50% or lower as a guideline. Note 3) This product is a tool intended for hole drilling. It cannot be used for cross-feed machining or helical machining. M169 DC x 2 DRILLING