Общий каталог Mitsubishi 2020 - 2021 - страница 1634

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

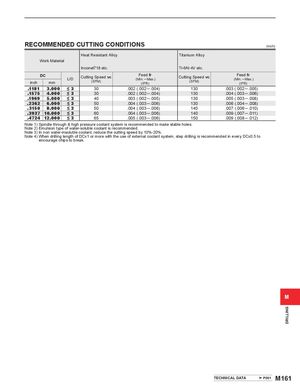

RECOMMENDED CUTTING CONDITIONS (inch) Heat Resistant Alloy Titanium Alloy Work Material Inconel718 etc. Ti-6Al-4V etc. DCinchmm L/D Cutting Speed vc(SFM) Feed fr(Min. ─ Max.)(IPR)Cutting Speed vc(SFM) Feed fr(Min. ─ Max.)(IPR) .1181 3.000 ≤3 30 .002 (.002 ─ .004) 130 .003 (.002 ─ .005) .1575 4.000 ≤3 30 .002 (.002 ─ .004) 130 .004 (.003 ─ .006) .1969 5.000 ≤3 40 .003 (.002 ─ .005) 130 .005 (.003 ─ .008) .2362 6.000 ≤3 50 .004 (.003 ─ .006) 130 .006 (.004 ─ .008) .3150 8.000 ≤3 50 .004 (.003 ─ .006) 140 .007 (.006 ─ .010) .3937 10.000 ≤3 60 .004 (.003 ─ .006) 140 .009 (.007 ─ .011) .4724 12.000 ≤3 65 .005 (.003 ─ .006) 150 .009 (.008 ─ .012) Note 1) Spindle through & high pressure coolant system is recommended to make stable holes. Note 2) Emulsion type of water-soluble coolant is recommended. Note 3) In non water-insoluble coolant, reduce the cutting speed by 10%-20%. Note 4) When drilling length of DCx1 or more with the use of external coolant system, step drilling is recommended in every DCx0.5 to encourage chips to break. M TECHNICAL DATA P001 M161 DRILLING