Общий каталог Mitsubishi 2020 - 2021 - страница 1623

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

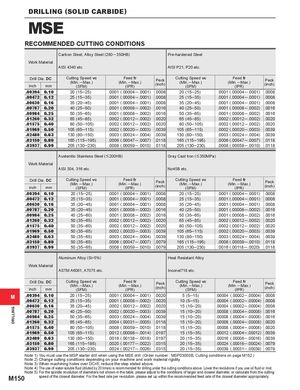

DRILLING (SOLID CARBIDE) MSE RECOMMENDED CUTTING CONDITIONS Carbon Steel, Alloy Steel (280 ─ 350HB) Pre-hardened Steel Work Material AISI 4340 etc. AISI P21, P20 etc. Drill Dia. DC Cutting Speed vc(Min. ─ Max.)inchmm(SFM)Feed fr(Min. ─ Max.)(IPR)Peck(inch)Cutting Speed vc(Min. ─ Max.)(SFM)Feed fr(Min. ─ Max.)(IPR)Peck(inch) .00394 0.10 20 (15─25) .0001 (.00004 ─ .0001) .0008 20 (15─25) .0001 (.00004 ─ .0001) .0008 .00472 0.12 25 (15─35) .0001 (.00004 ─ .0001) .0008 25 (15─35) .0001 (.00004 ─ .0001) .0008 .00630 0.16 35 (20─45) .0001 (.00004 ─ .0001) .0008 35 (20─45) .0001 (.00004 ─ .0001) .0008 .00787 0.20 40 (25─50) .0001 (.00008 ─ .0002) .0016 40 (25─50) .0001 (.00008 ─ .0002) .0016 .00984 0.25 50 (35─65) .0001 (.00008 ─ .0002) .0016 50 (35─65) .0001 (.00008 ─ .0002) .0016 .01260 0.32 65 (45─85) .0002 (.00012 ─ .0002) .0020 65 (45─85) .0002 (.00012 ─ .0002) .0020 .01575 0.40 80 (50─105) .0002 (.00012 ─ .0002) .0020 80 (50─105) .0002 (.00012 ─ .0002) .0020 .01969 0.50 105 (65─115) .0002 (.00020 ─ .0003) .0039 105 (65─115) .0002 (.00020 ─ .0003) .0039 .02480 0.63 130 (80─150) .0003 (.00024 ─ .0004) .0039 130 (80─150) .0003 (.00024 ─ .0004) .0039 .03150 0.80 165 (115─195) .0006 (.00047 ─ .0007) .0118 165 (115─195) .0006 (.00047 ─ .0007) .0118 .03937 0.99 205 (130─230) .0008 (.00059 ─ .0010) .0118 205 (130─230) .0008 (.00059 ─ .0010) .0118 Austenitic Stainless Steel ( < 200HB) Gray Cast Iron ( < 350MPa) Work Material AISI 304, 316 etc. No45B etc. Drill Dia. DC Cutting Speed vc(Min. ─ Max.)inchmm(SFM)Feed fr(Min. ─ Max.)(IPR)Peck(inch)Cutting Speed vc(Min. ─ Max.)(SFM)Feed fr(Min. ─ Max.)(IPR)Peck(inch) .00394 0.10 20 (15─25) .0001 (.00004 ─ .0001) .0008 20 (15─25) .0001 (.00004 ─ .0001) .0008 .00472 0.12 25 (15─35) .0001 (.00004 ─ .0001) .0008 25 (15─35) .0001 (.00004 ─ .0001) .0008 .00630 0.16 35 (20─45) .0001 (.00004 ─ .0001) .0008 35 (20─45) .0001 (.00004 ─ .0001) .0008 .00787 0.20 35 (20─45) .0001 (.00008 ─ .0002) .0016 40 (25─50) .0001 (.00008 ─ .0002) .0016 .00984 0.25 45 (25─60) .0001 (.00008 ─ .0002) .0016 50 (35─65) .0001 (.00008 ─ .0002) .0016 .01260 0.32 50 (35─65) .0002 (.00012 ─ .0002) .0020 65 (45─85) .0002 (.00012 ─ .0002) .0020 .01575 0.40 50 (35─60) .0002 (.00012 ─ .0002) .0020 80 (50─105) .0002 (.00012 ─ .0002) .0020 .01969 0.50 50 (35─65) .0002 (.00020 ─ .0003) .0039 105 (65─115) .0002 (.00020 ─ .0003) .0039 .02480 0.63 50 (35─65) .0003 (.00024 ─ .0004) .0039 130 (80─150) .0003 (.00024 ─ .0004) .0039 .03150 0.80 50 (35─65) .0006 (.00047 ─ .0007) .0079 165 (115─195) .0008 (.00059 ─ .0010) .0118 .03937 0.99 50 (35─65) .0008 (.00059 ─ .0010) .0079 205 (130─230) .0016 (.00118 ─ .0020) .0118 Aluminum Alloy (Si<5%) Heat Resistant Alloy Work Material ASTM A6061, A7075 etc. Inconel718 etc. Drill Dia. DC Cutting Speed vc(Min. ─ Max.)inchmm(SFM)Feed fr(Min. ─ Max.)(IPR)Peck(inch)Cutting Speed vc(Min. ─ Max.)(SFM)Feed fr(Min. ─ Max.)(IPR)Peck(inch) M .00394 0.10.004720.1220 (15─25)25 (15─35) .0001 (.00004 ─ .0001) .0020 5 (5─15).0001 (.00008 ─ .0002).002010 (5─15).00004(.00002 ─ .00004).0008.00004(.00002 ─ .00004).0008 .00630 0.16 35 (20─45) .0002 (.00012 ─ .0002) .0020 15 (10─20) .00004 (.00002 ─ .00004) .0008 .00787 0.20 40 (25─50) .0002 (.00020 ─ .0003) .0039 15 (10─20) .00008 (.00004 ─ .00008) .0016 .00984 0.25 50 (35─65) .0003 (.00024 ─ .0004) .0039 15 (10─20) .00008 (.00004 ─ .00008) .0016 .01260 0.32 65 (45─85) .0004 (.00031 ─ .0005) .0118 15 (10─20) .00008 (.00004 ─ .00008) .0020 .01575 0.40 80 (50─105) .0008 (.00059 ─ .0010) .0118 15 (15─20) .00008 (.00004 ─ .00008) .0020 .01969 0.50 105 (65─115) .0012 (.00098 ─ .0014) .0197 15 (15─35) .00012 (.00004 ─ .00012) .0039 .02480 0.63 130 (80─150) .0016 (.00138 ─ .0018) .0197 20 (15─35) .00016 (.00008 ─ .00016) .0039 .03150 0.80 165 (115─195) .0020 (.00177 ─ .0022) .0315 20 (15─35) .00024 (.00016 ─ .00024) .0079 .03937 0.99 205 (130─230) .0024 (.00217 ─ .0026) .0315 20 (15─35) .00039 (.00031 ─ .00039) .0079 Note 1) You must use the MSP starter drill when using the MSE drill. (Order number : MSP0300SB, Cutting conditions on page M152.) Note 2) Change cutting conditions depending on your machine and work material rigidity. Note 3) When machining holes over DCx5, reduce the step stated above. Note 4) The use of water-soluble fluid (diluted by 20 times) is recommended for drilling under the cutting conditions above. Lower the revolutions if you use oil fluid or mist. Note 5) For the spindle revolution of diameters not shown in the table, please adjust to the conditions of larger and closest diameter, or calculate from the cutting M150 speed of the closest diameter. For the feed rate per revolution, please set up within the recommended feed rate of the closest diameter appropriately. DRILLING