Общий каталог Mitsubishi 2020 - 2021 - страница 1610

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

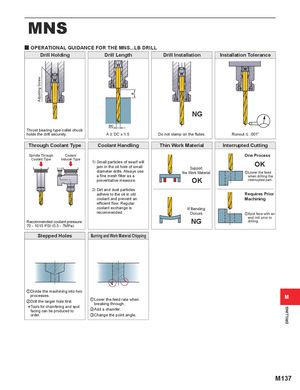

Adjusting Screw A DRILLING MNS y OPERATIONAL GUIDANCE FOR THE MNS...LB DRILL Drill Holding Drill Length Drill Installation Installation Tolerance NG DC Thrust bearing type collet chuck holds the drill securely. A > DC x 1.5 Do not clamp on the flutes. Runout < .001″ Through Coolant Type Coolant Handling Thin Work Material Interrupted Cutting Spindle Through Coolant One Process Coolant Type Inducer Type 1) Small particles of swarf willjam in the oil hole of smalldiameter drills. Always useOKSupportthe Work MaterialzLower the feed a fine mesh filter as a when drilling the preventative measure. OK interrupted part. 2) Dirt and dust particles adhere to the oil in old Requires Prior coolant and prevent an Machining efficient flow. Regular coolant exchange is If Bending recommended. Occurs zSpot face with an Recommended coolant pressure: NG end mill prior todrilling. 70 - 1015 PSI (0.5 - 7MPa). Stepped Holes Burring and Work Material Chipping zDivide the machining into two processes.xDrill the larger hole first.*Tools for chamfering and spotfacing can be produced tozLower the feed rate whenbreaking through.xAdd a chamfer. M order. cChange the point angle. M137