Общий каталог Mitsubishi 2020 - 2021 - страница 1553

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

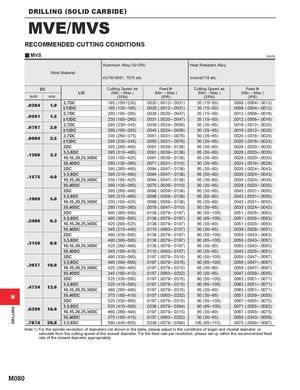

DRILLING (SOLID CARBIDE) MVE/MVS RECOMMENDED CUTTING CONDITIONS y MVS (inch) Aluminum Alloy (Si<5%) Heat Resistant Alloy Work Material ASTM 6061, 7075 etc. Inconel718 etc. DC Cutting Speed vc Feed fr Cutting Speed vc Feed fr L/D (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) (Min. ─ Max.) inch mm (SFM) (IPR) (SFM) (IPR) .0394 1.0 2,7DC≥12DC 195 (150─230) .0020 (.0012─.0031) 35 (15─50) .0008 (.0004─.0012)165 (130─195).0020 (.0012─.0031)35 (15─50).0008 (.0004─.0012) .0591 1.5 2,7DC≥12DC 260 (195─295) .0028 (.0020─.0047) 35 (15─50) .0012 (.0008─.0016)230 (180─260).0031 (.0020─.0047)35 (15─50).0012 (.0008─.0016) .0787 2.0 2,7DC≥12DC 295 (230─345) .0039 (.0024─.0059) 50 (35─65) .0016 (.0012─.0020)260 (195─295).0043 (.0024─.0059)50 (35─65).0016 (.0012─.0020) .0984 2.5 2,7DC≥12DC 330 (260─375) .0051 (.0031─.0079) 50 (35─65) .0020 (.0016─.0024)295 (230─345).0055 (.0031─.0079)50 (35─65).0020 (.0016─.0024) 2DC 395 (260─490) .0091 (.0039─.0138) 65 (30─80) .0028 (.0020─.0035) .1260 3.2 3,5,8DC10,15,20,25,30DC395 (310─460)330 (195─425).0091 (.0039─.0138).0091 (.0039─.0138)65 (50─80)65 (30─80).0028 (.0020─.0035).0028 (.0020─.0035) 35,40DC 260 (130─360) .0071 (.0031─.0110) 50 (30─65) .0024 (.0016─.0028) 2DC 395 (260─490) .0094 (.0047─.0138) 65 (30─80) .0035 (.0024─.0043) .1575 4.0 3,5,8DC10,15,20,25,30DC395 (310─460)330 (195─425).0094 (.0047─.0138).0094 (.0047─.0138)65 (50─80)65 (30─80).0035 (.0024─.0043).0035 (.0024─.0043) 35,40DC 260 (130─360) .0075 (.0039─.0110) 50 (30─65) .0028 (.0020─.0035) 2DC 395 (260─490) .0098 (.0059─.0138) 65 (30─80) .0043 (.0031─.0055) .1969 5.0 3,5,8DC10,15,20,25,30DC395 (310─460)330 (195─425).0098 (.0059─.0138).0098 (.0059─.0138)65 (50─80)65 (30─80).0043 (.0031─.0055).0043 (.0031─.0055) 35,40DC 260 (130─360) .0079 (.0047─.0110) 50 (30─65) .0035 (.0024─.0043) 2DC 490 (360─590) .0138 (.0079─.0197) 80 (50─100) .0051 (.0035─.0063) .2480 6.3 3,5,8DC10,15,20,25,30DC490 (395─560)425 (295─525).0138 (.0079─.0197).0138 (.0079─.0197)80 (65─100)65 (30─80).0051 (.0035─.0063).0051 (.0035─.0063) 35,40DC 345 (210─440) .0110 (.0063─.0157) 50 (30─65) .0039 (.0028─.0051) 2DC 490 (330─560) .0138 (.0079─.0197) 80 (50─100) .0055 (.0043─.0063) .3150 8.0 3,5,8DC10,15,20,25,30DC490 (395─560)425 (260─490).0138 (.0079─.0197).0138 (.0079─.0197)80 (65─100)65 (30─80).0055 (.0043─.0067).0055 (.0043─.0063) 35,40DC 345 (180─410) .0110 (.0063─.0157) 50 (30─65) .0043 (.0035─.0051) 2DC 490 (330─560) .0197 (.0079─.0315) 80 (50─100) .0059 (.0047─.0067) .3937 10.0 3,5,8DC10,15,20,25,30DC490 (395─560)425 (260─490).0197 (.0079─.0315).0197 (.0079─.0315)80 (65─100)65 (30─80).0059 (.0047─.0067).0059 (.0047─.0067) 35,40DC 345 (180─410) .0157 (.0063─.0252) 50 (30─65) .0047 (.0039─.0055) 2DC 525 (330─560) .0197 (.0079─.0315) 80 (50─100) .0063 (.0051─.0071) .4724 12.0 3,5,8DC10,15,20,25,30DC525 (410─590)460 (260─490).0197 (.0079─.0315).0197 (.0079─.0315)80 (65─100)65 (30─80).0063 (.0051─.0071).0063 (.0051─.0071) M 35,40DC 375 (180─410) .0157 (.0063─.0252) 50 (30─65) .0051 (.0039─.0055) 2DC 525 (330─560) .0197 (.0079─.0315) 80 (50─100) .0067 (.0055─.0075) .6299 16.0 3,5,8DC10,15,20,25,30DC525 (410─590)460 (260─490).0236 (.0079─.0394).0197 (.0079─.0315)80 (65─100)65 (30─80).0071 (.0055─.0083).0067 (.0055─.0075) 35,40DC 375 (180─410) .0157 (.0063─.0252) 50 (30─65) .0055 (.0043─.0059) .7874 20.0 3,5,8DC 560 (445─655) .0236 (.0079─.0394) 100 (65─115) .0075 (.0059─.0087) Note 1) For the spindle revolution of diameters not shown in the table, please adjust to the conditions of larger and closest diameter, or calculate from the cutting speed of the closest diameter. For the feed rate per revolution, please set up within the recommended feed rate of the closest diameter appropriately. M080 DRILLING