Общий каталог Mitsubishi 2020 - 2021 - страница 1044

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

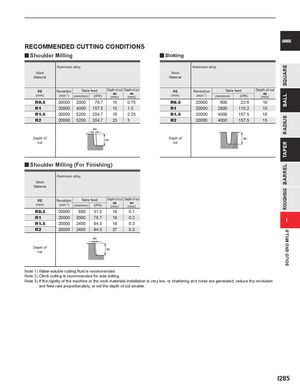

SQUAREBALLRADIUSTAPERBARRELROUGHINGSOLID END MILLS CARBIDE RECOMMENDED CUTTING CONDITIONS y Shoulder Milling y Slotting Aluminum alloy Aluminum alloy Work Work Material Material RE(mm) Revolution Table feed(min-1)(mm/min)(IPR)Depth of cutDepth of cutapae(mm)(mm)RE(mm) Revolution Table feed(min-1)(mm/min)(IPR)Depth of cutap(mm) R0.5 20000 2000 78.7 15 0.75 R0.5 20000 600 23.6 10 R1 20000 4000 157.5 15 1.5 R1 20000 2800 110.2 10 R1.5 20000 5200 204.7 15 2.25 R1.5 20000 4000 157.5 10 R2 20000 5200 204.7 23 3 R2 20000 4000 157.5 15 ae Depth of ap Depth of ap cut cut y Shoulder Milling (For Finishing) Aluminum alloy Work Material RE(mm) Revolution Table feed(min-1)(mm/min)(IPR)Depth of cutDepth of cutapae(mm)(mm) R0.5 20000 800 31.5 18 0.1 R1 20000 2000 78.7 18 0.2R1.520000240094.5180.3 I R2 20000 2400 94.5 27 0.3 ae Depth of ap cut Note 1) Water-soluble cutting fluid is recommended. Note 2) Climb cutting is recommended for side milling. Note 3) If the rigidity of the machine or the work materials installation is very low, or chattering and noise are generated, reduce the revolution and feed rate proportionately, or set the depth of cut smaller. I285