Каталог SGS микро инструмент 2021 - страница 125

Навигация

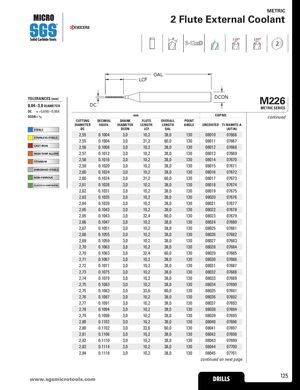

METRIC 2 Flute External Coolant 118° 130° 2 OAL LCF TOLERANCES (mm)0,04–3,0 DIAMETER DC DCON M226 METRIC SERIES DC = +0,000/–0,008 DCON = h6 mm EDP NO. continued CUTTING DECIMAL SHANK FLUTE OVERALL POINT DIAMETER EQUIV. DIAMETER LENGTH LENGTH ANGLE UNCOATED TI-NAMITE-A STEELS DC DCON LCF OAL (AlTiN) 2,55 0.1004 3,0 10,2 38,0 130 08010 07666 STAINLESS STEELS 2,55 0.1004 3,0 31,2 60,0 130 08011 07667 CAST IRON 2,56 0.1008 3,0 10,2 38,0 130 08012 07668 HIGH TEMP ALLOYS 2,57 0.1012 3,0 10,2 38,0 130 08013 07669 TITANIUM 2,58 0.1016 3,0 10,2 38,0 130 08014 07670 2,59 0.1020 3,0 10,2 38,0 130 08015 07671 HARDENED STEELS 2,60 0.1024 3,0 10,2 38,0 130 08016 07672 NON-FERROUS 2,60 0.1024 3,0 31,2 60,0 130 08017 07673 PLASTICS/COMPOSITES 2,61 0.1028 3,0 10,2 38,0 130 08018 07674 2,62 0.1031 3,0 10,2 38,0 130 08019 07675 2,63 0.1035 3,0 10,2 38,0 130 08020 07676 2,64 0.1039 3,0 10,2 38,0 130 08021 07677 2,65 0.1043 3,0 10,2 38,0 130 08022 07678 2,65 0.1043 3,0 32,4 60,0 130 08023 07679 2,66 0.1047 3,0 10,2 38,0 130 08024 07680 2,67 0.1051 3,0 10,2 38,0 130 08025 07681 2,68 0.1055 3,0 10,2 38,0 130 08026 07682 2,69 0.1059 3,0 10,2 38,0 130 08027 07683 2,70 0.1063 3,0 10,2 38,0 130 08028 07684 2,70 0.1063 3,0 32,4 60,0 130 08029 07685 2,71 0.1067 3,0 10,2 38,0 130 08030 07686 2,72 0.1071 3,0 10,2 38,0 130 08031 07687 2,73 0.1075 3,0 10,2 38,0 130 08032 07688 2,74 0.1079 3,0 10,2 38,0 130 08033 07689 2,75 0.1083 3,0 10,2 38,0 130 08034 07690 2,75 0.1083 3,0 33,6 60,0 130 08035 07691 2,76 0.1087 3,0 10,2 38,0 130 08036 07692 2,77 0.1091 3,0 10,2 38,0 130 08037 07693 2,78 0.1094 3,0 10,2 38,0 130 08038 07694 2,79 0.1098 3,0 10,2 38,0 130 08039 07695 2,80 0.1102 3,0 10,2 38,0 130 08040 07696 2,80 0.1102 3,0 33,6 60,0 130 08041 07697 2,81 0.1106 3,0 10,2 38,0 130 08042 07698 2,82 0.1110 3,0 10,2 38,0 130 08043 07699 2,83 0.1114 3,0 10,2 38,0 130 08044 07700 2,84 0.1118 3,0 10,2 38,0 130 08045 07701 continued on next page www.sgsmicrDoRtoILoLlSs.com DRILLS 125

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2018

Общий каталог SGS 2018 Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33