Каталог SGS микро инструмент 2021 - страница 123

Навигация

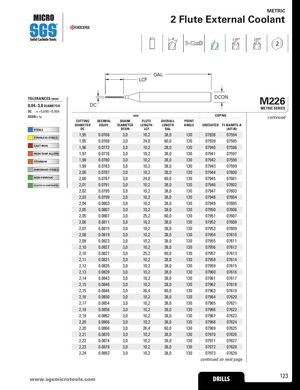

METRIC 2 Flute External Coolant 118° 130° 2 OAL LCF TOLERANCES (mm)0,04–3,0 DIAMETER DC DCON M226 METRIC SERIES DC = +0,000/–0,008 DCON = h6 mm EDP NO. continued CUTTING DECIMAL SHANK FLUTE OVERALL POINT DIAMETER EQUIV. DIAMETER LENGTH LENGTH ANGLE UNCOATED TI-NAMITE-A STEELS DC DCON LCF OAL (AlTiN) 1,95 0.0768 3,0 10,2 38,0 130 07938 07594 STAINLESS STEELS 1,95 0.0768 3,0 24,0 60,0 130 07939 07595 CAST IRON 1,96 0.0772 3,0 10,2 38,0 130 07940 07596 HIGH TEMP ALLOYS 1,97 0.0776 3,0 10,2 38,0 130 07941 07597 TITANIUM 1,98 0.0780 3,0 10,2 38,0 130 07942 07598 1,99 0.0783 3,0 10,2 38,0 130 07943 07599 HARDENED STEELS 2,00 0.0787 3,0 10,2 38,0 130 07944 07600 NON-FERROUS 2,00 0.0787 3,0 24,0 60,0 130 07945 07601 PLASTICS/COMPOSITES 2,01 0.0791 3,0 10,2 38,0 130 07946 07602 2,02 0.0795 3,0 10,2 38,0 130 07947 07603 2,03 0.0799 3,0 10,2 38,0 130 07948 07604 2,04 0.0803 3,0 10,2 38,0 130 07949 07605 2,05 0.0807 3,0 10,2 38,0 130 07950 07606 2,05 0.0807 3,0 25,2 60,0 130 07951 07607 2,06 0.0811 3,0 10,2 38,0 130 07952 07608 2,07 0.0815 3,0 10,2 38,0 130 07953 07609 2,08 0.0819 3,0 10,2 38,0 130 07954 07610 2,09 0.0823 3,0 10,2 38,0 130 07955 07611 2,10 0.0827 3,0 10,2 38,0 130 07956 07612 2,10 0.0827 3,0 25,2 60,0 130 07957 07613 2,11 0.0831 3,0 10,2 38,0 130 07958 07614 2,12 0.0835 3,0 10,2 38,0 130 07959 07615 2,13 0.0839 3,0 10,2 38,0 130 07960 07616 2,14 0.0843 3,0 10,2 38,0 130 07961 07617 2,15 0.0846 3,0 10,2 38,0 130 07962 07618 2,15 0.0846 3,0 26,4 60,0 130 07963 07619 2,16 0.0850 3,0 10,2 38,0 130 07964 07620 2,17 0.0854 3,0 10,2 38,0 130 07965 07621 2,18 0.0858 3,0 10,2 38,0 130 07966 07622 2,19 0.0862 3,0 10,2 38,0 130 07967 07623 2,20 0.0866 3,0 10,2 38,0 130 07968 07624 2,20 0.0866 3,0 26,4 60,0 130 07969 07625 2,21 0.0870 3,0 10,2 38,0 130 07970 07626 2,22 0.0874 3,0 10,2 38,0 130 07971 07627 2,23 0.0878 3,0 10,2 38,0 130 07972 07628 2,24 0.0882 3,0 10,2 38,0 130 07973 07629 continued on next page www.sgsmicrDoRtoILoLlSs.com DRILLS 123

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2018

Общий каталог SGS 2018 Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33