Каталог SGS микро инструмент 2021 - страница 121

Навигация

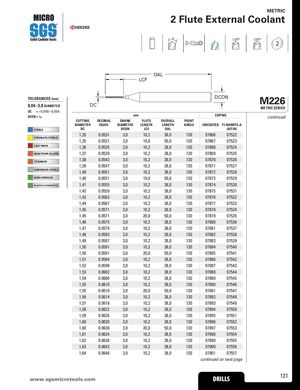

METRIC 2 Flute External Coolant 118° 130° 2 OAL LCF TOLERANCES (mm)0,04–3,0 DIAMETER DC DCON M226 METRIC SERIES DC = +0,000/–0,008 DCON = h6 mm EDP NO. continued CUTTING DECIMAL SHANK FLUTE OVERALL POINT DIAMETER EQUIV. DIAMETER LENGTH LENGTH ANGLE UNCOATED TI-NAMITE-A STEELS DC DCON LCF OAL (AlTiN) 1,35 0.0531 3,0 10,2 38,0 130 07866 07522 STAINLESS STEELS 1,35 0.0531 3,0 19,0 50,0 130 07867 07523 CAST IRON 1,36 0.0535 3,0 10,2 38,0 130 07868 07524 HIGH TEMP ALLOYS 1,37 0.0539 3,0 10,2 38,0 130 07869 07525 TITANIUM 1,38 0.0543 3,0 10,2 38,0 130 07870 07526 1,39 0.0547 3,0 10,2 38,0 130 07871 07527 HARDENED STEELS 1,40 0.0551 3,0 10,2 38,0 130 07872 07528 NON-FERROUS 1,40 0.0551 3,0 19,0 50,0 130 07873 07529 PLASTICS/COMPOSITES 1,41 0.0555 3,0 10,2 38,0 130 07874 07530 1,42 0.0559 3,0 10,2 38,0 130 07875 07531 1,43 0.0563 3,0 10,2 38,0 130 07876 07532 1,44 0.0567 3,0 10,2 38,0 130 07877 07533 1,45 0.0571 3,0 10,2 38,0 130 07878 07534 1,45 0.0571 3,0 20,0 50,0 130 07879 07535 1,46 0.0575 3,0 10,2 38,0 130 07880 07536 1,47 0.0579 3,0 10,2 38,0 130 07881 07537 1,48 0.0583 3,0 10,2 38,0 130 07882 07538 1,49 0.0587 3,0 10,2 38,0 130 07883 07539 1,50 0.0591 3,0 10,2 38,0 130 07884 07540 1,50 0.0591 3,0 20,0 50,0 130 07885 07541 1,51 0.0594 3,0 10,2 38,0 130 07886 07542 1,52 0.0598 3,0 10,2 38,0 130 07887 07543 1,53 0.0602 3,0 10,2 38,0 130 07888 07544 1,54 0.0606 3,0 10,2 38,0 130 07889 07545 1,55 0.0610 3,0 10,2 38,0 130 07890 07546 1,55 0.0610 3,0 20,0 50,0 130 07891 07547 1,56 0.0614 3,0 10,2 38,0 130 07892 07548 1,57 0.0618 3,0 10,2 38,0 130 07893 07549 1,58 0.0622 3,0 10,2 38,0 130 07894 07550 1,59 0.0626 3,0 10,2 38,0 130 07895 07551 1,60 0.0630 3,0 10,2 38,0 130 07896 07552 1,60 0.0630 3,0 20,0 50,0 130 07897 07553 1,61 0.0634 3,0 10,2 38,0 130 07898 07554 1,62 0.0638 3,0 10,2 38,0 130 07899 07555 1,63 0.0642 3,0 10,2 38,0 130 07900 07556 1,64 0.0646 3,0 10,2 38,0 130 07901 07557 continued on next page www.sgsmicrDoRtoILoLlSs.com DRILLS 121

Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS монолитный инструмент из композитных материалов

Каталог SGS монолитный инструмент из композитных материалов Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2018

Общий каталог SGS 2018 Общий каталог SGS 2021

Общий каталог SGS 2021 Каталог SGS фрезы для труднообрабатываемых материалов Series 33

Каталог SGS фрезы для труднообрабатываемых материалов Series 33