Каталог SGS монолитный инструмент из композитных материалов - страница 19

Навигация

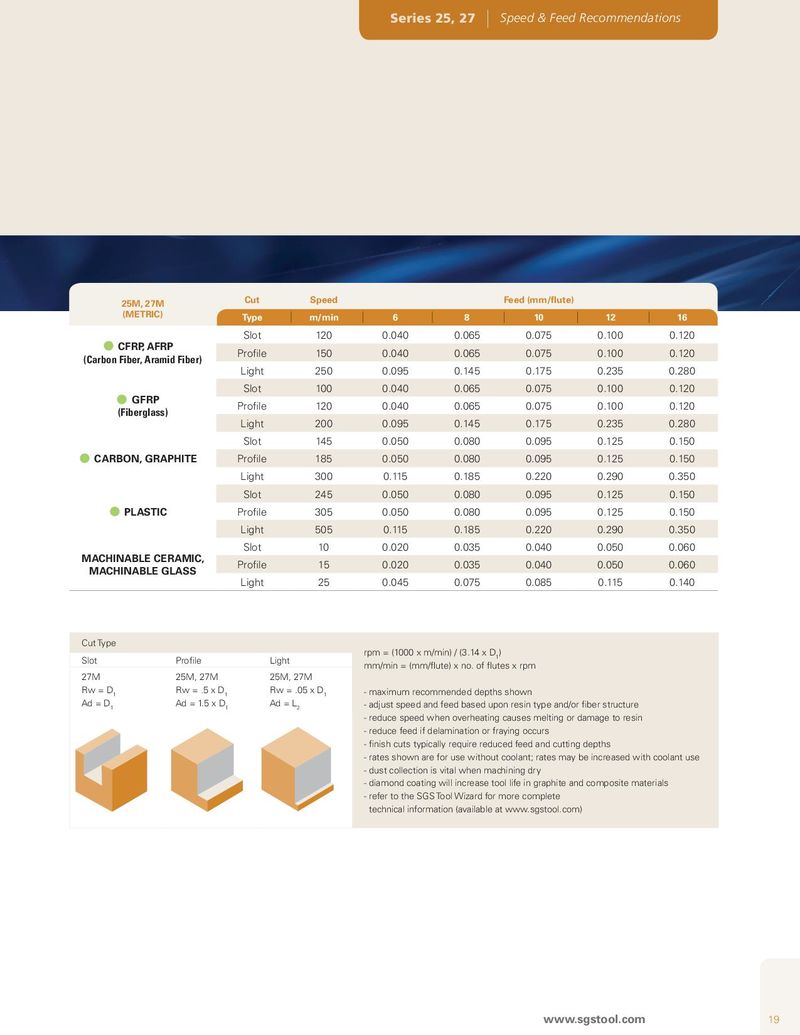

Series 25, 27 Speed & Feed Recommendations 25M, 27M Cut Speed Feed (mm/flute) (METRIC) Type m/min 6 8 10 12 16 Slot 120 0.040 0.065 0.075 0.100 0.120 CFRP, AFRP Profile 150 0.040 0.065 0.075 0.100 0.120 (Carbon Fiber, Aramid Fiber) Light 250 0.095 0.145 0.175 0.235 0.280 Slot 100 0.040 0.065 0.075 0.100 0.120 GFRP Profile 120 0.040 0.065 0.075 0.100 0.120 (Fiberglass) Light 200 0.095 0.145 0.175 0.235 0.280 Slot 145 0.050 0.080 0.095 0.125 0.150 CARBON, GRAPHITE Profile 185 0.050 0.080 0.095 0.125 0.150 Light 300 0.115 0.185 0.220 0.290 0.350 Slot 245 0.050 0.080 0.095 0.125 0.150 PLASTIC Profile 305 0.050 0.080 0.095 0.125 0.150 Light 505 0.115 0.185 0.220 0.290 0.350 Slot 10 0.020 0.035 0.040 0.050 0.060 MACHINABLE CERAMIC, Profile 15 0.020 0.035 0.040 0.050 0.060 MACHINABLE GLASS Light 25 0.045 0.075 0.085 0.115 0.140 Cut Type Slot Profile Light rpm = (1000 x m/min) / (3.14 x D1) mm/min = (mm/flute) x no. of flutes x rpm 27M 25M, 27M 25M, 27M Rw = D1 Rw = .5 x D1 Rw = .05 x D1 - maximum recommended depths shown Ad = D1 Ad = 1.5 x D1 Ad = L2 - adjust speed and feed based upon resin type and/or fiber structure - reduce speed when overheating causes melting or damage to resin - reduce feed if delamination or fraying occurs - finish cuts typically require reduced feed and cutting depths - rates shown are for use without coolant; rates may be increased with coolant use - dust collection is vital when machining dry - diamond coating will increase tool life in graphite and composite materials - refer to the SGS Tool Wizard for more complete technical information (available at www.sgstool.com) www.sgstool.com 19

Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS микроинструмент

Каталог SGS микроинструмент Общий каталог SGS 2021

Общий каталог SGS 2021 Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском Каталог SGS фрезы для обработки пластика PCR series

Каталог SGS фрезы для обработки пластика PCR series