Основной каталог Kennametal невращающиеся инструменты - страница 972

Навигация

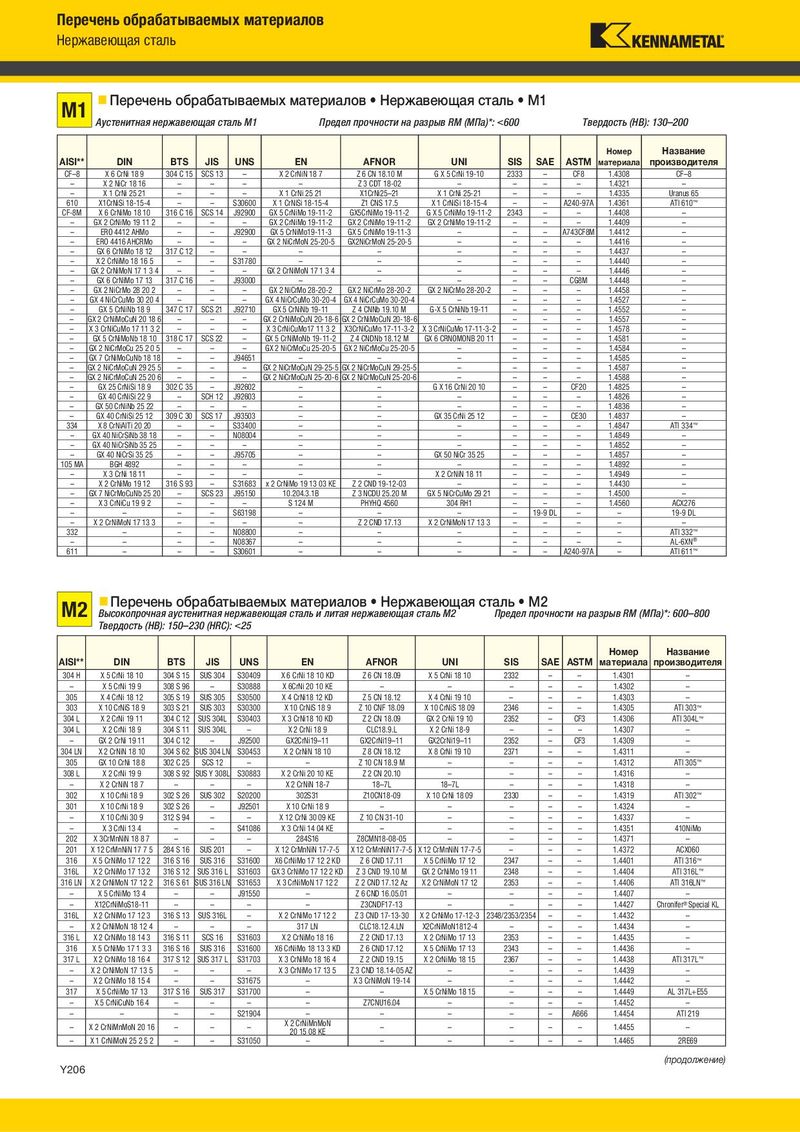

Перечень обрабатываемых материалов Нержавеющая сталь M1 Перечень обрабатываемых материалов • Нержавеющая сталь • M1 Аустенитная нержавеющая сталь M1 Предел прочности на разрыв RM (МПа)*: <600 Твердость (HB): 130–200 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя CF–8 X 6 CrNi 18 9 304 C 15 SCS 13 – X 2 CrNiN 18 7 Z 6 CN 18.10 M G X 5 CrNi 19-10 2333 – CF8 1.4308 CF–8 – X 2 NiCr 18 16 – – – – Z 3 CDT 18-02 – – – – 1.4321 – – X 1 CrNi 25 21 – – – X 1 CrNi 25 21 X1CrNi25–21 X 1 CrNi 25-21 – – – 1.4335 Uranus 65 610 X1CrNiSi 18-15-4 – – S30600 X 1 CrNiSi 18-15-4 Z1 CNS 17.5 X 1 CrNiSi 18-15-4 – – A240-97A 1.4361 ATI 610™ CF-8M X 6 CrNiMo 18 10 316 C 16 SCS 14 J92900 GX 5 CrNiMo 19-11-2 GX5CrNiMo 19-11-2 G X 5 CrNiMo 19-11-2 2343 – – 1.4408 – – GX 2 CrNiMo 19 11 2 – – – GX 2 CrNiMo 19-11-2 GX 2 CrNiMo 19-11-2 GX 2 CrNiMo 19-11-2 – – – 1.4409 – – ERO 4412 AHMo – – J92900 GX 5 CrNiMo19-11-3 GX 5 CrNiMo 19-11-3 – – – A743CF8M 1.4412 – – ERO 4416 AHCRMo – – – GX 2 NiCrMoN 25-20-5 GX2NiCrMoN 25-20-5 – – – – 1.4416 – – GX 6 CrNiMo 18 12 317 C 12 – – – – – – – – 1.4437 – – X 2 CrNiMo 18 16 5 – – S31780 – – – – – – 1.4440 – – GX 2 CrNiMoN 17 1 3 4 – – – GX 2 CrNiMoN 17 1 3 4 – – – – – 1.4446 – – GX 6 CrNiMo 17 13 317 C 16 – J93000 – – – – – CG8M 1.4448 – – GX 2 NiCrMo 28 20 2 – – – GX 2 NiCrMo 28-20-2 GX 2 NiCrMo 28-20-2 GX 2 NiCrMo 28-20-2 – – – 1.4458 – – GX 4 NiCrCuMo 30 20 4 – – – GX 4 NiCrCuMo 30-20-4 GX 4 NiCrCuMo 30-20-4 – – – – 1.4527 – – GX 5 CrNiNb 18 9 347 C 17 SCS 21 J92710 GX 5 CrNiNb 19-11 Z 4 CNNb 19.10 M G-X 5 CrNiNb 19-11 – – – 1.4552 – – GX 2 CrNiMoCuN 20 18 6 – – – GX 2 CrNiMoCuN 20-18-6 GX 2 CrNiMoCuN 20-18-6 – – – – 1.4557 – – X 3 CrNiCuMo 17 11 3 2 – – – X 3 CrNiCuMo17 11 3 2 X3CrNiCuMo 17-11-3-2 X 3 CrNiCuMo 17-11-3-2 – – – 1.4578 – – GX 5 CrNiMoNb 18 10 318 C 17 SCS 22 – GX 5 CrNiMoNb 19-11-2 Z 4 CNDNb 18.12 M GX 6 CRNOMONB 20 11 – – – 1.4581 – – GX 2 NiCrMoCu 25 2 0 5 – – – GX 2 NiCrMoCu 25-20-5 GX 2 NiCrMoCu 25-20-5 – – – – 1.4584 – – GX 7 CrNiMoCuNb 18 18 – – J94651 – – – – – – 1.4585 – – GX 2 NiCrMoCuN 29 25 5 – – – GX 2 NiCrMoCuN 29-25-5 GX 2 NiCrMoCuN 29-25-5 – – – – 1.4587 – – GX 2 NiCrMoCuN 25 20 6 – – – GX 2 NiCrMoCuN 25-20-6 GX 2 NiCrMoCuN 25-20-6 – – – – 1.4588 – – GX 25 CrNiSi 18 9 302 C 35 – J92602 – – G X 16 CrNi 20 10 – – CF20 1.4825 – – GX 40 CrNiSi 22 9 – SCH 12 J92603 – – – – – – 1.4826 – – GX 50 CrNiNb 25 22 – – – – – – – – – 1.4836 – – GX 40 CrNiSi 25 12 309 C 30 SCS 17 J93503 – – GX 35 CrNi 25 12 – – CE30 1.4837 – 334 X 8 CrNiAlTi 20 20 – – S33400 – – – – – – 1.4847 ATI 334™ – GX 40 NiCrSiNb 38 18 – – N08004 – – – – – – 1.4849 – – GX 40 NiCrSiNb 35 25 – – – – – – – – – 1.4852 – – GX 40 NiCrSi 35 25 – – J95705 – – GX 50 NiCr 35 25 – – – 1.4857 – 105 MA BGH 4892 – – – – – – – – – 1.4892 – – X 3 CrNi 18 11 – – – – – X 2 CrNiN 18 11 – – – 1.4949 – – X 2 CrNiMo 19 12 316 S 93 – S31683 x 2 CrNiMo 19 13 03 KE Z 2 CND 19-12-03 – – – – 1.4430 – – GX 7 NiCrMoCuNb 25 20 – SCS 23 J95150 10.204.3.1B Z 3 NCDU 25.20 M GX 5 NiCrCuMo 29 21 – – – 1.4500 – – X 3 CrNiCu 19 9 2 – – – S 124 M PHYHQ 4560 304 RH1 – – – 1.4560 ACX276 – – – – S63198 – – – – 19-9 DL – – 19-9 DL – X 2 CrNiMoN 17 13 3 – – – – Z 2 CND 17.13 X 2 CrNiMoN 17 13 3 – – – – – 332 – – – N08800 – – – – – – – ATI 332™ – – – – N08367 – – – – – – – AL-6XN® 611 – – – S30601 – – – – – A240-97A – ATI 611™ M2 Перечень обрабатываемых материалов • Нержавеющая сталь • M2 Высокопрочная аустенитная нержавеющая сталь и литая нержавеющая сталь M2 Предел прочности на разрыв RM (МПа)*: 600–800 Твердость (HB): 150–230 (HRC): <25 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя 304 H X 5 CrNi 18 10 304 S 15 SUS 304 S30409 X 6 CrNi 18 10 KD Z 6 CN 18.09 X 5 CrNi 18 10 2332 – – 1.4301 – – X 5 CrNi 19 9 308 S 96 – S30888 X 6CrNi 20 10 KE – – – – – 1.4302 – 305 X 4 CrNi 18 12 305 S 19 SUS 305 S30500 X 4 CrNi18 12 KD Z 5 CN 18.12 X 4 CrNi 19 10 – – – 1.4303 – 303 X 10 CrNiS 18 9 303 S 21 SUS 303 S30300 X 10 CrNiS 18 9 Z 10 CNF 18.09 X 10 CrNiS 18 09 2346 – – 1.4305 ATI 303™ 304 L X 2 CrNi 19 11 304 C 12 SUS 304L S30403 X 3 CrNi18 10 KD Z 2 CN 18.09 GX 2 CrNi 19 10 2352 – CF3 1.4306 ATI 304L™ 304 L X 2 CrNi 18 9 304 S 11 SUS 304L – X 2 CrNi 18 9 CLC18.9.L X 2 CrNi 18-9 – – – 1.4307 – – GX 2 CrNi 19 11 304 C 12 – J92500 GX2CrNi19–11 GX2CrNi19–11 GX2CrNi19–11 2352 – CF3 1.4309 – 304 LN X 2 CrNiN 18 10 304 S 62 SUS 304 LN S30453 X 2 CrNiN 18 10 Z 8 CN 18.12 X 8 CrNi 19 10 2371 – – 1.4311 – 305 GX 10 CrNi 18 8 302 C 25 SCS 12 – – Z 10 CN 18.9 M – – – – 1.4312 ATI 305™ 308 L X 2 CrNi 19 9 308 S 92 SUS Y 308L S30883 X 2 CrNi 20 10 KE Z 2 CN 20.10 – – – – 1.4316 – – X 2 CrNiN 18 7 – – – X 2 CrNiN 18-7 18–7L 18–7L – – – 1.4318 – 302 X 10 CrNi 18 9 302 S 26 SUS 302 S20200 302S31 Z10CN18-09 X 10 CrNi 18 09 2330 – – 1.4319 ATI 302™ 301 X 10 CrNi 18 9 302 S 26 – J92501 X 10 CrNi 18 9 – – – – – 1.4324 – – X 10 CrNi 30 9 312 S 94 – – X 12 CrNi 30 09 KE Z 10 CN 31-10 – – – – 1.4337 – – X 3 CrNi 13 4 – – S41086 X 3 CrNi 14 04 KE – – – – – 1.4351 410NiMo 202 X 3CrMnNiN 18 8 7 – – – 284S16 Z8CMN18-08-05 – – – – 1.4371 – 201 X 12 CrMnNiN 17 7 5 284 S 16 SUS 201 – X 12 CrMnNiN 17-7-5 X 12 CrMnNiN17-7-5 X 12 CrMnNiN 17-7-5 – – – 1.4372 ACX060 316 X 5 CrNiMo 17 12 2 316 S 16 SUS 316 S31600 X6 CrNiMo 17 12 2 KD Z 6 CND 17.11 X 5 CrNiMo 17 12 2347 – – 1.4401 ATI 316™ 316L X 2 CrNiMo 17 13 2 316 S 12 SUS 316 L S31603 GX 3 CrNiMo 17 12 2 KD Z 3 CND 19.10 M GX 2 CrNiMo 19 11 2348 – – 1.4404 ATI 316L™ 316 LN X 2 CrNiMoN 17 12 2 316 S 61 SUS 316 LN S31653 X 3 CrNiMoN 17 12 2 Z 2 CND 17.12 Az X 2 CrNiMoN 17 12 2353 – – 1.4406 ATI 316LN™ – X 5 CrNiMo 13 4 – – J91550 – Z 6 CND 16.05.01 – – – – 1.4407 – – X12CrNiMoS18-11 – – – – Z3CNDF17-13 – – – – 1.4427 Chronifer® Special KL 316L X 2 CrNiMo 17 12 3 316 S 13 SUS 316L – X 2 CrNiMo 17 12 2 Z 3 CND 17-13-30 X 2 CrNiMo 17-12-3 2348/2353/2354 – – 1.4432 – – X 2 CrNiMoN 18 12 4 – – – 317 LN CLC18.12.4.LN X2CrNiMoN1812-4 – – – 1.4434 – 316 L X 2 CrNiMo 18 14 3 316 S 11 SCS 16 S31603 X 2 CrNiMo 18 16 Z 2 CND 17.13 X 2 CrNiMo 17 13 2353 – – 1.4435 – 316 X 5 CrNiMo 17 1 3 3 316 S 16 SUS 316 S31600 X6 CrNiMo 18 13 3 KD Z 6 CND 17.12 X 5 CrNiMo 17 13 2343 – – 1.4436 – 317 L X 2 CrNiMo 18 16 4 317 S 12 SUS 317 L S31703 X 3 CrNiMo 18 16 4 Z 2 CND 19.15 X 2 CrNiMo 18 15 2367 – – 1.4438 ATI 317L™ – X 2 CrNiMoN 17 13 5 – – – X 3 CrNiMo 17 13 5 Z 3 CND 18.14-05 AZ – – – – 1.4439 – – X 2 CrNiMo 18 15 4 – – S31675 – X 3 CrNiMoN 19-14 – – – – 1.4442 – 317 X 5 CrNiMo 17 13 317 S 16 SUS 317 S31700 – – X 5 CrNiMo 18 15 – – – 1.4449 AL 317L+E55 – X 5 CrNiCuNb 16 4 – – – – Z7CNU16.04 – – – – 1.4452 – – – – – S21904 – – – – – A666 1.4454 ATI 219 – X 2 CrNiMnMoN 20 16 – – – X 2 CrNiMnMoN – – – – – 1.4455 – 20 15 08 KE – X 1 CrNiMoN 25 2 5 2 – – S31050 – – – – – – 1.4465 2RE69 (продолжение) Y206

Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1 Каталог Kennametal инновации 2020.2

Каталог Kennametal инновации 2020.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Основной каталог Kennametal вращающиеся инструменты 2018

Основной каталог Kennametal вращающиеся инструменты 2018 Каталог Kennametal инновации 2020.1

Каталог Kennametal инновации 2020.1 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2