Основной каталог Kennametal невращающиеся инструменты - страница 973

Навигация

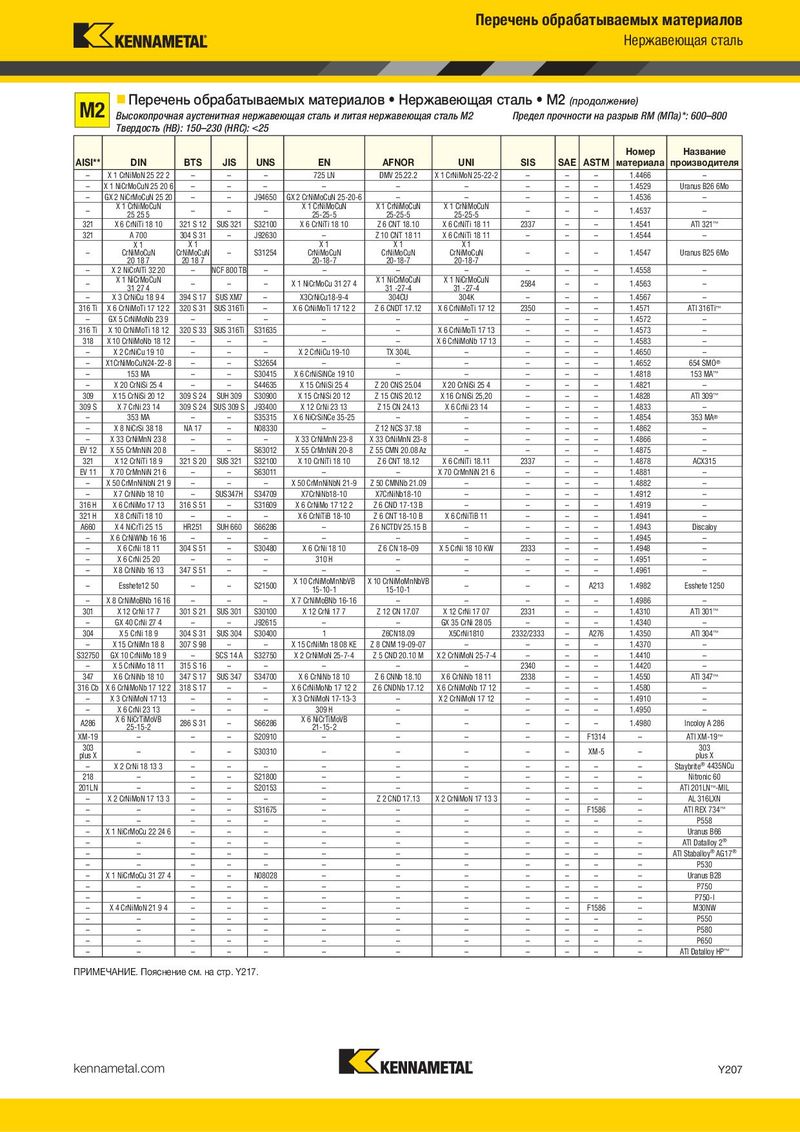

Перечень обрабатываемых материалов Нержавеющая сталь M2 Перечень обрабатываемых материалов • Нержавеющая сталь • M2 (продолжение) Высокопрочная аустенитная нержавеющая сталь и литая нержавеющая сталь M2 Предел прочности на разрыв RM (МПа)*: 600–800 Твердость (HB): 150–230 (HRC): <25 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя – X 1 CrNiMoN 25 22 2 – – – 725 LN DMV 25.22.2 X 1 CrNiMoN 25-22-2 – – – 1.4466 – – X 1 NiCrMoCuN 25 20 6 – – – – – – – – – 1.4529 Uranus B26 6Mo – GX 2 NiCrMoCuN 25 20 – – J94650 GX 2 CrNiMoCuN 25-20-6 – – – – – 1.4536 – – X 1 CrNiMoCuN – – – X 1 CrNiMoCuN X 1 CrNiMoCuN X 1 CrNiMoCuN – – – 1.4537 – 25 25 5 25-25-5 25-25-5 25-25-5 321 X 6 CrNiTi 18 10 321 S 12 SUS 321 S32100 X 6 CrNiTi 18 10 Z 6 CNT 18.10 X 6 CrNiTi 18 11 2337 – – 1.4541 ATI 321™ 321 A 700 304 S 31 – J92630 – Z 10 CNT 18 11 X 6 CrNiTi 18 11 – – – 1.4544 – X1 X1 X1 X1 X1 – CrNiMoCuN CrNiMoCuN – S31254 CrNiMoCuN CrNiMoCuN CrNiMoCuN – – – 1.4547 Uranus B25 6Mo 20 18 7 20 18 7 20-18-7 20-18-7 20-18-7 – X 2 NiCrAlTi 32 20 – NCF 800 TB – – – – – – – 1.4558 – – X 1 NiCrMoCuN – – – X 1 NiCrMoCu 31 27 4 X 1 NiCrMoCuN X 1 NiCrMoCuN 2584 – – 1.4563 – 31 27 4 31 -27-4 31 -27-4 – X 3 CrNiCu 18 9 4 394 S 17 SUS XM7 – X3CrNiCu18-9-4 304CU 304K – – – 1.4567 – 316 Ti X 6 CrNiMoTi 17 12 2 320 S 31 SUS 316Ti – X 6 CrNiMoTi 17 12 2 Z 6 CNDT 17.12 X 6 CrNiMoTi 17 12 2350 – – 1.4571 ATI 316Ti™ – GX 5 CrNiMoNb 23 9 – – – – – – – – – 1.4572 – 316 Ti X 10 CrNiMoTi 18 12 320 S 33 SUS 316Ti S31635 – – X 6 CrNiMoTi 17 13 – – – 1.4573 – 318 X 10 CrNiMoNb 18 12 – – – – – X 6 CrNiMoNb 17 13 – – – 1.4583 – – X 2 CrNiCu 19 10 – – – X 2 CrNiCu 19-10 TX 304L – – – – 1.4650 – – X1CrNiMoCuN24-22-8 – – S32654 – – – – – – 1.4652 654 SMO® – 153 MA – – S30415 X 6 CrNiSiNCe 19 10 – – – – – 1.4818 153 MA™ – X 20 CrNiSi 25 4 – – S44635 X 15 CrNiSi 25 4 Z 20 CNS 25.04 X 20 CrNiSi 25 4 – – – 1.4821 – 309 X 15 CrNiSi 20 12 309 S 24 SUH 309 S30900 X 15 CrNiSi 20 12 Z 15 CNS 20.12 X 16 CrNiSi 25,20 – – – 1.4828 ATI 309™ 309 S X 7 CrNi 23 14 309 S 24 SUS 309 S J93400 X 12 CrNi 23 13 Z 15 CN 24.13 X 6 CrNi 23 14 – – – 1.4833 – – 353 MA – – S35315 X 6 NiCrSiNCe 35-25 – – – – – 1.4854 353 MA® – X 8 NiCrSi 38 18 NA 17 – N08330 – Z 12 NCS 37.18 – – – – 1.4862 – – X 33 CrNiMnN 23 8 – – – X 33 CrNiMnN 23-8 X 33 CrNiMnN 23-8 – – – – 1.4866 – EV 12 X 55 CrMnNiN 20 8 – – S63012 X 55 CrMnNiN 20-8 Z 55 CMN 20.08 Az – – – – 1.4875 – 321 X 12 CrNiTi 18 9 321 S 20 SUS 321 S32100 X 10 CrNiTi 18 10 Z 6 CNT 18.12 X 6 CrNiTi 18.11 2337 – – 1.4878 ACX315 EV 11 X 70 CrMnNiN 21 6 – – S63011 – – X 70 CrMnNiN 21 6 – – – 1.4881 – – X 50 CrMnNiNbN 21 9 – – – X 50 CrMnNiNbN 21-9 Z 50 CMNNb 21.09 – – – – 1.4882 – – X 7 CrNiNb 18 10 – SUS347H S34709 X7CrNiNb18-10 X7CrNiNb18-10 – – – – 1.4912 – 316 H X 6 CrNiMo 17 13 316 S 51 – S31609 X 6 CrNiMo 17 12 2 Z 6 CND 17-13 B – – – – 1.4919 – 321 H X 8 CrNiTi 18 10 – – – X 6 CrNiTiB 18-10 Z 6 CNT 18-10 B X 6 CrNiTiB 11 – – – 1.4941 – A660 X 4 NiCrTi 25 15 HR251 SUH 660 S66286 – Z 6 NCTDV 25.15 B – – – – 1.4943 Discaloy – X 6 CrNiWNb 16 16 – – – – – – – – – 1.4945 – – X 6 CrNi 18 11 304 S 51 – S30480 X 6 CrNi 18 10 Z 6 CN 18–09 X 5 CrNi 18 10 KW 2333 – – 1.4948 – – X 6 CrNi 25 20 – – – 310 H – – – – – 1.4951 – – X 8 CrNiNb 16 13 347 S 51 – – – – – – – – 1.4961 – – Esshete12 50 – – S21500 X 10 CrNiMoMnNbVB X 10 CrNiMoMnNbVB – – – A213 1.4982 Esshete 1250 15-10-1 15-10-1 – X 8 CrNiMoBNb 16 16 – – – X 7 CrNiMoBNb 16-16 – – – – – 1.4986 – 301 X 12 CrNi 17 7 301 S 21 SUS 301 S30100 X 12 CrNi 17 7 Z 12 CN 17.07 X 12 CrNi 17 07 2331 – – 1.4310 ATI 301™ – GX 40 CrNi 27 4 – – J92615 – – GX 35 CrNi 28 05 – – – 1.4340 – 304 X 5 CrNi 18 9 304 S 31 SUS 304 S30400 1 Z6CN18.09 X5CrNi1810 2332/2333 – A276 1.4350 ATI 304™ – X 15 CrNiMn 18 8 307 S 98 – – X 15 CrNiMn 18 08 KE Z 8 CNM 19-09-07 – – – – 1.4370 – S32750 GX 10 CrNiMo 18 9 – SCS 14 A S32750 X 2 CrNiMoN 25-7-4 Z 5 CND 20.10 M X 2 CrNiMoN 25-7-4 – – – 1.4410 – – X 5 CrNiMo 18 11 315 S 16 – – – – – 2340 – – 1.4420 – 347 X 6 CrNiNb 18 10 347 S 17 SUS 347 S34700 X 6 CrNiNb 18 10 Z 6 CNNb 18.10 X 6 CrNiNb 18 11 2338 – – 1.4550 ATI 347™ 316 Cb X 6 CrNiMoNb 17 12 2 318 S 17 – – X 6 CrNiMoNb 17 12 2 Z 6 CNDNb 17.12 X 6 CrNiMoNb 17 12 – – – 1.4580 – – X 3 CrNiMoN 17 13 – – – X 3 CrNiMoN 17-13-3 – X 2 CrNiMoN 17 12 – – – 1.4910 – – X 6 CrNi 23 13 – – – 309 H – – – – – 1.4950 – A286 X 6 NiCrTiMoVB 286 S 31 – S66286 X 6 NiCrTiMoVB – – – – – 1.4980 Incoloy A 286 25-15-2 21-15-2 XM-19 – – – S20910 – – – – – F1314 – ATI XM-19™ 303 – – – S30310 – – – – – XM-5 – 303 plus X plus X – X 2 CrNi 18 13 3 – – – – – – – – – – Staybrite® 4435NCu 218 – – – S21800 – – – – – – – Nitronic 60 201LN – – – S20153 – – – – – – – ATI 201LN™-MIL – X 2 CrNiMoN 17 13 3 – – – – Z 2 CND 17.13 X 2 CrNiMoN 17 13 3 – – – – AL 316LXN – – – – S31675 – – – – – F1586 – ATI REX 734™ – – – – – – – – – – – – P558 – X 1 NiCrMoCu 22 24 6 – – – – – – – – – – Uranus B66 – – – – – – – – – – – – ATI Datalloy 2® – – – – – – – – – – – – ATI Staballoy® AG17® – – – – – – – – – – – – P530 – X 1 NiCrMoCu 31 27 4 – – N08028 – – – – – – – Uranus B28 – – – – – – – – – – – – P750 – – – – – – – – – – – – P750-I – X 4 CrNiMoN 21 9 4 – – – – – – – – F1586 – M30NW – – – – – – – – – – – – P550 – – – – – – – – – – – – P580 – – – – – – – – – – – – P650 – – – – – – – – – – – – ATI Datalloy HP™ ПРИМЕЧАНИЕ. Пояснение см. на стр. Y217. kennametal.com Y207

Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1 Каталог Kennametal инновации 2020.2

Каталог Kennametal инновации 2020.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Основной каталог Kennametal вращающиеся инструменты 2018

Основной каталог Kennametal вращающиеся инструменты 2018 Каталог Kennametal инновации 2020.1

Каталог Kennametal инновации 2020.1 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2