Основной каталог Kennametal невращающиеся инструменты - страница 970

Навигация

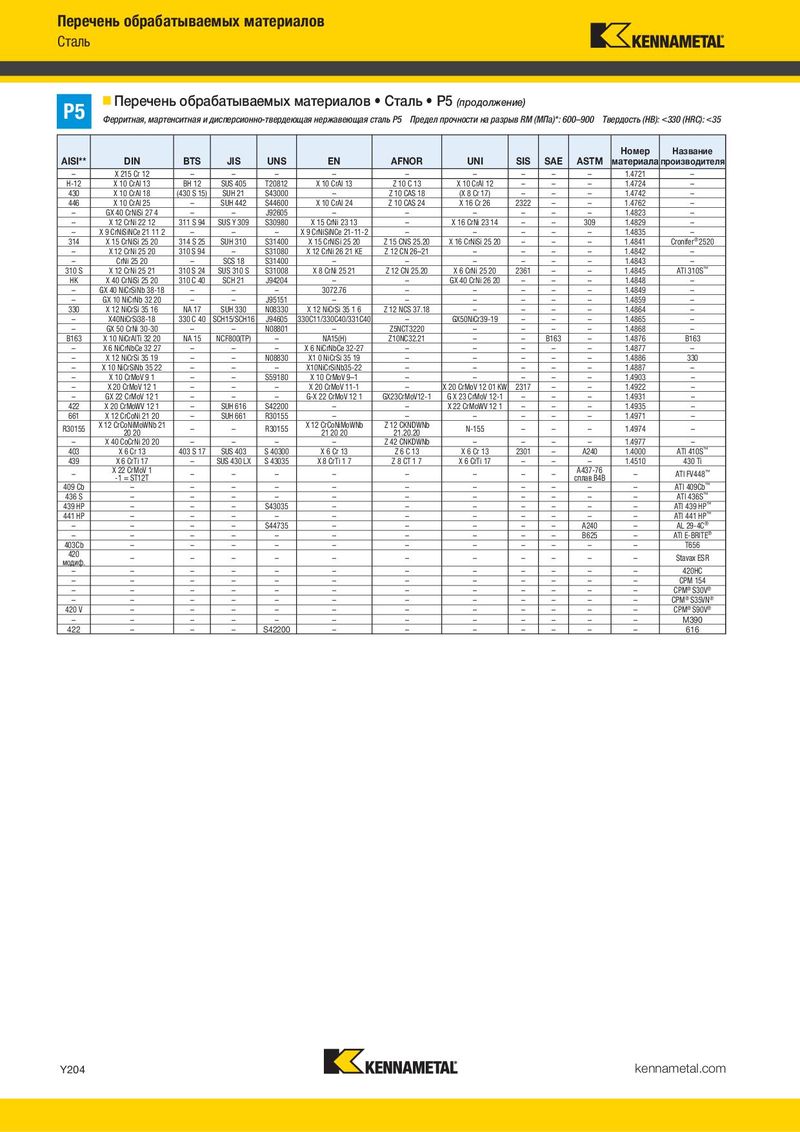

Перечень обрабатываемых материалов Сталь P5 Перечень обрабатываемых материалов • Сталь • P5 (продолжение) Ферритная, мартенситная и дисперсионно-твердеющая нержавеющая сталь P5 Предел прочности на разрыв RM (МПа)*: 600–900 Твердость (HB): <330 (HRC): <35 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя – X 215 Cr 12 – – – – – – – – – 1.4721 – H-12 X 10 CrAl 13 BH 12 SUS 405 T20812 X 10 CrAl 13 Z 10 C 13 X 10 CrAl 12 – – – 1.4724 – 430 X 10 CrAl 18 (430 S 15) SUH 21 S43000 – Z 10 CAS 18 (X 8 Cr 17) – – – 1.4742 – 446 X 10 CrAl 25 – SUH 442 S44600 X 10 CrAl 24 Z 10 CAS 24 X 16 Cr 26 2322 – – 1.4762 – – GX 40 CrNiSi 27 4 – – J92605 – – – – – – 1.4823 – – X 12 CrNi 22 12 311 S 94 SUS Y 309 S30980 X 15 CrNi 23 13 – X 16 CrNi 23 14 – – 309 1.4829 – – X 9 CrNiSiNCe 21 11 2 – – – X 9 CrNiSiNCe 21-11-2 – – – – – 1.4835 – 314 X 15 CrNiSi 25 20 314 S 25 SUH 310 S31400 X 15 CrNiSi 25 20 Z 15 CNS 25.20 X 16 CrNiSi 25 20 – – – 1.4841 Cronifer® 2520 – X 12 CrNi 25 20 310 S 94 – S31080 X 12 CrNi 26 21 KE Z 12 CN 26–21 – – – – 1.4842 – – CrNi 25 20 – SCS 18 S31400 – – – – – – 1.4843 – 310 S X 12 CrNi 25 21 310 S 24 SUS 310 S S31008 X 8 CrNi 25 21 Z 12 CN 25.20 X 6 CrNi 25 20 2361 – – 1.4845 ATI 310S™ HK X 40 CrNiSi 25 20 310 C 40 SCH 21 J94204 – – GX 40 CrNi 26 20 – – – 1.4848 – – GX 40 NiCrSiNb 38-18 – – – 3072.76 – – – – – 1.4849 – – GX 10 NiCrNb 32 20 – – J95151 – – – – – – 1.4859 – 330 X 12 NiCrSi 35 16 NA 17 SUH 330 N08330 X 12 NiCrSi 35 1 6 Z 12 NCS 37.18 – – – – 1.4864 – – X40NiCrSi38-18 330 C 40 SCH15/SCH16 J94605 330C11/330C40/331C40 – GX50NiCr39-19 – – – 1.4865 – – GX 50 CrNi 30-30 – – N08801 – Z5NCT3220 – – – – 1.4868 – B163 X 10 NiCrAlTi 32 20 NA 15 NCF800(TP) – NA15(H) Z10NC32.21 – – B163 – 1.4876 B163 – X 6 NiCrNbCe 32 27 – – – X 6 NiCrNbCe 32-27 – – – – – 1.4877 – – X 12 NiCrSi 35 19 – – N08830 X1 0 NiCrSi 35 19 – – – – – 1.4886 330 – X 10 NiCrSiNb 35 22 – – – X10NiCrSiNb35-22 – – – – – 1.4887 – – X 10 CrMoV 9 1 – – S59180 X 10 CrMoV 9–1 – – – – – 1.4903 – – X 20 CrMoV 12 1 – – – X 20 CrMoV 11-1 – X 20 CrMoV 12 01 KW 2317 – – 1.4922 – – GX 22 CrMoV 12 1 – – – G-X 22 CrMoV 12 1 GX23CrMoV12-1 G X 23 CrMoV 12-1 – – – 1.4931 – 422 X 20 CrMoWV 12 1 – SUH 616 S42200 – – X 22 CrMoWV 12 1 – – – 1.4935 – 661 X 12 CrCoNi 21 20 – SUH 661 R30155 – – – – – – 1.4971 – R30155 X 12 CrCoNiMoWNb 21 – – R30155 X 12 CrCoNiMoWNb Z 12 CKNDWNb N-155 – – – 1.4974 – 20 20 21 20 20 21.20.20 – X 40 CoCrNi 20 20 – – – – Z 42 CNKDWNb – – – – 1.4977 – 403 X 6 Cr 13 403 S 17 SUS 403 S 40300 X 6 Cr 13 Z 6 C 13 X 6 Cr 13 2301 – A240 1.4000 ATI 410S™ 439 X 6 CrTi 17 – SUS 430 LX S 43035 X 8 CrTi 1 7 Z 8 CT 1 7 X 6 CrTi 17 – – – 1.4510 430 Ti – X 22 CrMoV 1 – – – – – – – – A437-76 – ATI FV448™ -1 = ST12T сплав B4B 409 Cb – – – – – – – – – – – ATI 409Cb™ 436 S – – – – – – – – – – – ATI 436S™ 439 HP – – – S43035 – – – – – – – ATI 439 HP™ 441 HP – – – – – – – – – – – ATI 441 HP™ – – – – S44735 – – – – – A240 – AL 29-4C® – – – – – – – – – – B625 – ATI E-BRITE® 403Cb – – – – – – – – – – – T656 420 – – – – – – – – – – – Stavax ESR модиф. – – – – – – – – – – – – 420HC – – – – – – – – – – – – CPM 154 – – – – – – – – – – – – CPM® S30V® – – – – – – – – – – – – CPM® S35VN® 420 V – – – – – – – – – – – CPM® S90V® – – – – – – – – – – – – M390 422 – – – S42200 – – – – – – – 616 Y204 kennametal.com

Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1 Каталог Kennametal инновации 2020.2

Каталог Kennametal инновации 2020.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Основной каталог Kennametal вращающиеся инструменты 2018

Основной каталог Kennametal вращающиеся инструменты 2018 Каталог Kennametal инновации 2020.1

Каталог Kennametal инновации 2020.1 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2