Основной каталог Kennametal невращающиеся инструменты - страница 969

Навигация

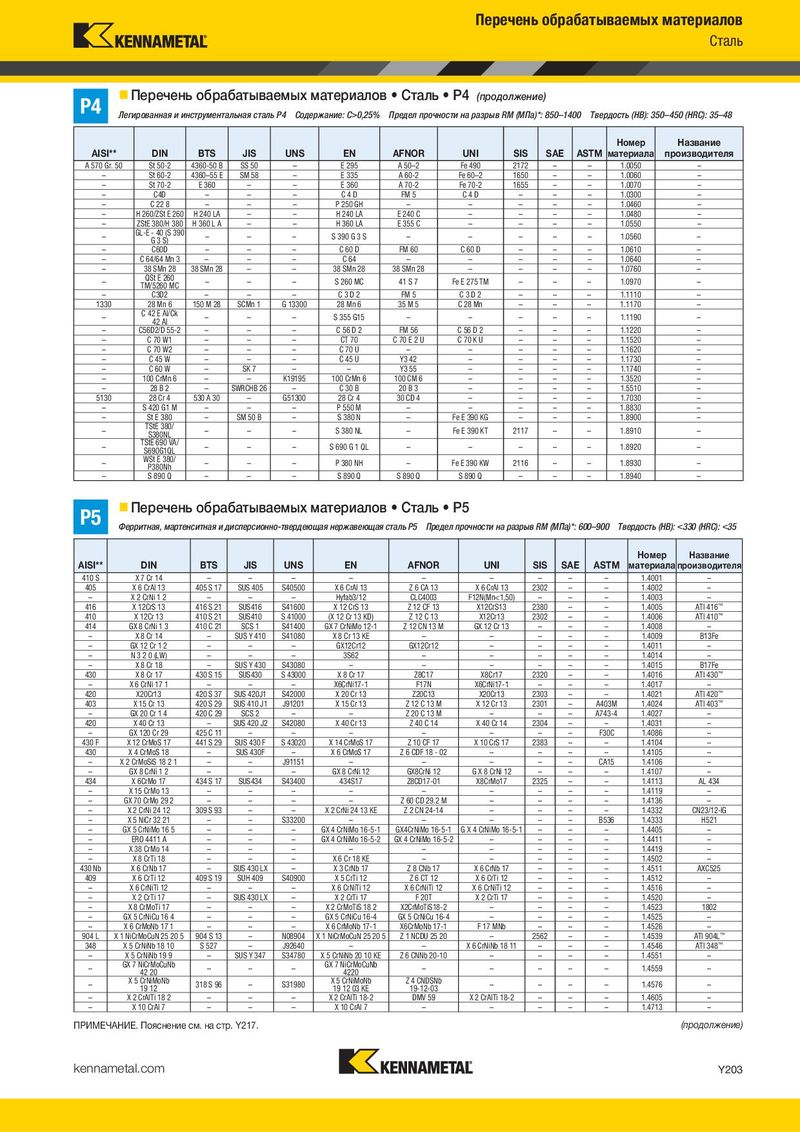

Перечень обрабатываемых материалов Сталь P4 Перечень обрабатываемых материалов • Сталь • P4 (продолжение) Легированная и инструментальная сталь P4 Содержание: C>0,25% Предел прочности на разрыв RM (МПа)*: 850–1400 Твердость (HB): 350–450 (HRC): 35–48 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя A 570 Gr. 50 St 50-2 4360-50 B SS 50 – E 295 A 50–2 Fe 490 2172 – – 1.0050 – – St 60-2 4360–55 E SM 58 – E 335 A 60-2 Fe 60–2 1650 – – 1.0060 – – St 70-2 E 360 – – E 360 A 70-2 Fe 70-2 1655 – – 1.0070 – – C4D – – – C4D FM 5 C4D – – – 1.0300 – – C 22 8 – – – P 250 GH – – – – – 1.0460 – – H 260/ZSt E 260 H 240 LA – – H 240 LA E 240 C – – – – 1.0480 – – ZStE 380/H 380 H 360 L A – – H 360 LA E 355 C – – – – 1.0550 – – GL-E - 40 (S 390 – – – S 390 G 3 S – – – – – 1.0560 – G 3 S) – C60D – – – C 60 D FM 60 C 60 D – – – 1.0610 – – C 64/64 Mn 3 – – – C 64 – – – – – 1.0640 – – 38 SMn 28 38 SMn 28 – – 38 SMn 28 38 SMn 28 – – – – 1.0760 – – QSt E 260 – – – S 260 MC 41 S 7 Fe E 275 TM – – – 1.0970 – TM/5260 MC – C3D2 – – – C3D2 FM 5 C3D2 – – – 1.1110 – 1330 28 Mn 6 150 M 28 SCMn 1 G 13300 28 Mn 6 35 M 5 C 28 Mn – – – 1.1170 – – C 42 E Al/Ck – – – S 355 G15 – – – – – 1.1190 – 42 Al – C56D2/D 55-2 – – – C 56 D 2 FM 56 C 56 D 2 – – – 1.1220 – – C 70 W1 – – – CT 70 C 70 E 2 U C 70 K U – – – 1.1520 – – C 70 W2 – – – C 70 U – – – – – 1.1620 – – C 45 W – – – C 45 U Y3 42 – – – – 1.1730 – – C 60 W – SK 7 – – Y3 55 – – – – 1.1740 – – 100 CrMn 6 – – K19195 100 CrMn 6 100 CM 6 – – – – 1.3520 – – 28 B 2 – SWRCHB 26 – C 30 B 20 B 3 – – – – 1.5510 – 5130 28 Cr 4 530 A 30 – G51300 28 Cr 4 30 CD 4 – – – – 1.7030 – – S 420 G1 M – – – P 550 M – – – – – 1.8830 – – St E 380 – SM 50 B – S 380 N – Fe E 390 KG – – – 1.8900 – – TStE 380/ – – – S 380 NL – Fe E 390 KT 2117 – – 1.8910 – S380NL – TStE 690 VA/ – – – S 690 G 1 QL – – – – – 1.8920 – S690G1QL – WSt E 380/ – – – P 380 NH – Fe E 390 KW 2116 – – 1.8930 – P380Nh – S 890 Q – – – S 890 Q S 890 Q S 890 Q – – – 1.8940 – P5 Перечень обрабатываемых материалов • Сталь • P5 Ферритная, мартенситная и дисперсионно-твердеющая нержавеющая сталь P5 Предел прочности на разрыв RM (МПа)*: 600–900 Твердость (HB): <330 (HRC): <35 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя 410 S X 7 Cr 14 – – – – – – – – – 1.4001 – 405 X 6 CrAl 13 405 S 17 SUS 405 S40500 X 6 CrAl 13 Z 6 CA 13 X 6 CrAl 13 2302 – – 1.4002 – – X 2 CrNi 1 2 – – – Hyfab3/12 CLC4003 F12N(Mn<1,50) – – – 1.4003 – 416 X 12CrS 13 416 S 21 SUS416 S41600 X 12 CrS 13 Z 12 CF 13 X12CrS13 2380 – – 1.4005 ATI 416™ 410 X 12Cr 13 410 S 21 SUS410 S 41000 (X 12 Cr 13 KD) Z 12 C 13 X12Cr13 2302 – – 1.4006 ATI 410™ 414 GX 8 CrNi 1 3 410 C 21 SCS 1 S41400 GX 7 CrNiMo 12-1 Z 12 CN 13 M GX 12 Cr 13 – – – 1.4008 – – X 8 Cr 14 – SUS Y 410 S41080 X 8 Cr 13 KE – – – – – 1.4009 B13Fe – GX 12 Cr 1 2 – – – GX12Cr12 GX12Cr12 – – – – 1.4011 – – N 3 2 0 (LW) – – – 3S62 – – – – – 1.4014 – – X 8 Cr 18 – SUS Y 430 S43080 – – – – – – 1.4015 B17Fe 430 X 8 Cr 17 430 S 15 SUS430 S 43000 X 8 Cr 17 Z8C17 X8Cr17 2320 – – 1.4016 ATI 430™ – X 6 CrNi 17 1 – – – X6CrNi17-1 F17N X6CrNi17-1 – – – 1.4017 – 420 X20Cr13 420 S 37 SUS 420J1 S42000 X 20 Cr 13 Z20C13 X20Cr13 2303 – – 1.4021 ATI 420™ 403 X 15 Cr 13 420 S 29 SUS 410 J1 J91201 X 15 Cr 13 Z 12 C 13 M X 12 Cr 13 2301 – A403M 1.4024 ATI 403™ – GX 20 Cr 1 4 420 C 29 SCS 2 – – Z 20 C 13 M – – – A743-4 1.4027 – 420 X 40 Cr 13 – SUS 420 J2 S42080 X 40 Cr 13 Z 40 C 14 X 40 Cr 14 2304 – – 1.4031 – – GX 120 Cr 29 425 C 11 – – – – – – – F30C 1.4086 – 430 F X 12 CrMoS 17 441 S 29 SUS 430 F S 43020 X 14 CrMoS 17 Z 10 CF 17 X 10 CrS 17 2383 – – 1.4104 – 430 X 4 CrMoS 18 – SUS 430F – X 6 CrMoS 17 Z 6 CDF 18 - 02 – – – – 1.4105 – – X 2 CrMoSiS 18 2 1 – – J91151 – – – – – CA15 1.4106 – – GX 8 CrNi 1 2 – – – GX 8 CrNi 12 GX8CrNi 12 G X 8 CrNi 12 – – – 1.4107 – 434 X 6CrMo 17 434 S 17 SUS434 S43400 434S17 Z8CD17-01 X8CrMo17 2325 – – 1.4113 AL 434 – X 15 CrMo 13 – – – – – – – – – 1.4119 – – GX 70 CrMo 29 2 – – – – Z 60 CD 29.2 M – – – – 1.4136 – – X 2 CrNi 24 12 309 S 93 – – X 2 CrNi 24 13 KE Z 2 CN 24-14 – – – – 1.4332 CN23/12-IG – X 5 NiCr 32 21 – – S33200 – – – – – B536 1.4333 H521 – GX 5 CrNiMo 16 5 – – – GX 4 CrNiMo 16-5-1 GX4CrNiMo 16-5-1 G X 4 CrNiMo 16-5-1 – – – 1.4405 – – ERO 4411 A – – – GX 4 CrNiMo 16-5-2 GX 4 CrNiMo 16-5-2 – – – – 1.4411 – – X 38 CrMo 14 – – – – – – – – – 1.4419 – – X 8 CrTi 18 – – – X 6 Cr 18 KE – – – – – 1.4502 – 430 Nb X 6 CrNb 17 – SUS 430 LX – X 3 CrNb 17 Z 8 CNb 17 X 6 CrNb 17 – – – 1.4511 AXC525 409 X 6 CrTi 12 409 S 19 SUH 409 S40900 X 5 CrTi 12 Z 6 CT 12 X 6 CrTi 12 – – – 1.4512 – – X 6 CrNiTi 12 – – – X 6 CrNiTi 12 X 6 CrNiTi 12 X 6 CrNiTi 12 – – – 1.4516 – – X 2 CrTi 17 – SUS 430 LX – X 2 CrTi 17 F 20T X 2 CrTi 17 – – – 1.4520 – – X 8 CrMoTi 17 – – – X 2 CrMoTiS 18 2 X2CrMoTiS18-2 – – – – 1.4523 1802 – GX 5 CrNiCu 16 4 – – – GX 5 CrNiCu 16-4 GX 5 CrNiCu 16-4 – – – – 1.4525 – – X 6 CrMoNb 17 1 – – – X 6 CrMoNb 17-1 X6CrMoNb 17-1 F 17 MNb – – – 1.4526 – 904 L X 1 NiCrMoCuN 25 20 5 904 S 13 – N08904 X 1 NiCrMoCuN 25 20 5 Z 1 NCDU 25 20 – 2562 – – 1.4539 ATI 904L™ 348 X 5 CrNiNb 18 10 S 527 – J92640 – – X 6 CrNiNb 18 11 – – – 1.4546 ATI 348™ – X 5 CrNiNb 19 9 – SUS Y 347 S34780 X 5 CrNiNb 20 10 KE Z 6 CNNb 20-10 – – – – 1.4551 – – GX 7 NiCrMoCuNb – – – GX 7 NiCrMoCuNb – – – – – 1.4559 – 42 20 4220 – X 5 CrNiMoNb 318 S 96 – S31980 X 5 CrNiMoNb Z 4 CNDSNb – – – – 1.4576 – 19 12 19 12 03 KE 19-12-03 – X 2 CrAlTi 18 2 – – – X 2 CrAlTi 18-2 DMV 59 X 2 CrAlTi 18-2 – – – 1.4605 – – X 10 CrAl 7 – – – X 10 CrAl 7 – – – – – 1.4713 – ПРИМЕЧАНИЕ. Пояснение см. на стр. Y217. (продолжение) kennametal.com Y203

Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1 Каталог Kennametal инновации 2020.2

Каталог Kennametal инновации 2020.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Основной каталог Kennametal вращающиеся инструменты 2018

Основной каталог Kennametal вращающиеся инструменты 2018 Каталог Kennametal инновации 2020.1

Каталог Kennametal инновации 2020.1 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2