Основной каталог Kennametal невращающиеся инструменты - страница 966

Навигация

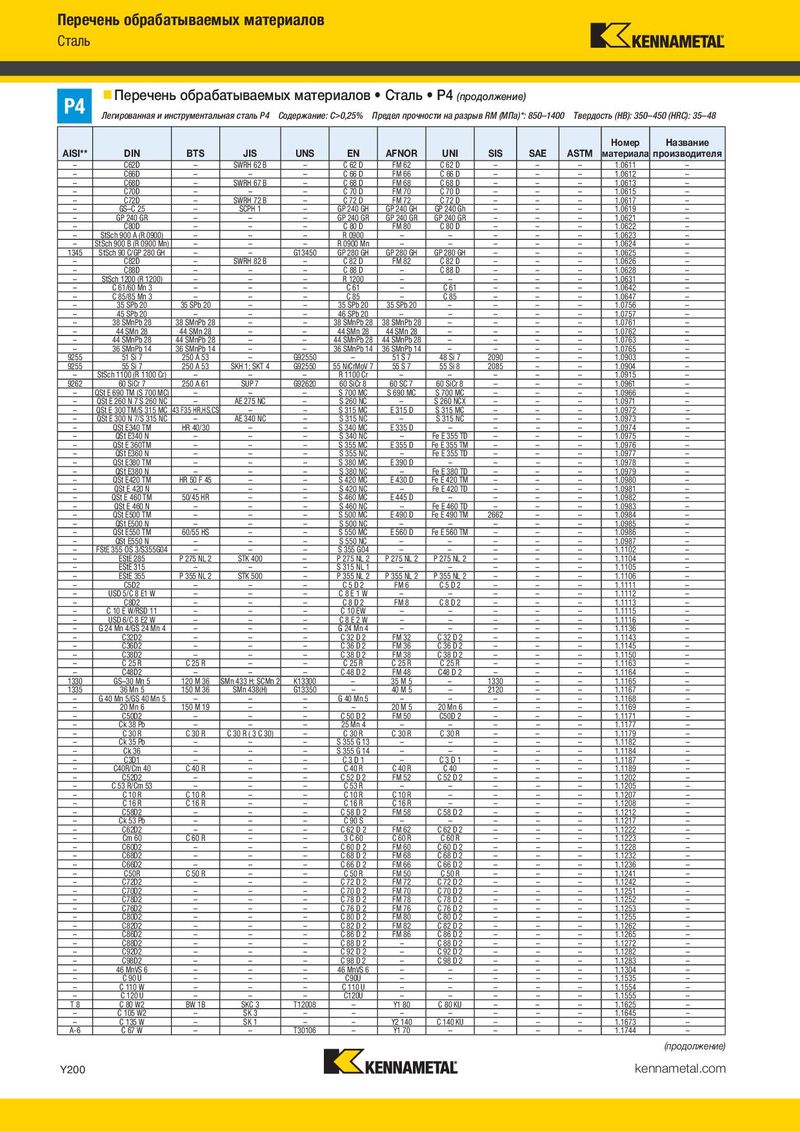

Перечень обрабатываемых материалов Сталь P4 Перечень обрабатываемых материалов • Сталь • P4 (продолжение) Легированная и инструментальная сталь P4 Содержание: C>0,25% Предел прочности на разрыв RM (МПа)*: 850–1400 Твердость (HB): 350–450 (HRC): 35–48 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя – C62D – SWRH 62 B – C 62 D FM 62 C 62 D – – – 1.0611 – – C66D – – – C 66 D FM 66 C 66 D – – – 1.0612 – – C68D – SWRH 67 B – C 68 D FM 68 C 68 D – – – 1.0613 – – C70D – – – C 70 D FM 70 C 70 D – – – 1.0615 – – C72D – SWRH 72 B – C 72 D FM 72 C 72 D – – – 1.0617 – – GS–C 25 – SCPH 1 – GP 240 GH GP 240 GH GP 240 Gh – – – 1.0619 – – GP 240 GR – – – GP 240 GR GP 240 GR GP 240 GR – – – 1.0621 – – C80D – – – C 80 D FM 80 C 80 D – – – 1.0622 – – StSch 900 A (R 0900) – – – R 0900 – – – – – 1.0623 – – StSch 900 B (R 0900 Mn) – – – R 0900 Mn – – – – – 1.0624 – 1345 StSch 90 C/GP 280 GH – – G13450 GP 280 GH GP 280 GH GP 280 GH – – – 1.0625 – – C82D – SWRH 82 B – C 82 D FM 82 C 82 D – – – 1.0626 – – C88D – – – C 88 D – C 88 D – – – 1.0628 – – StSch 1200 (R 1200) – – – R 1200 – – – – – 1.0631 – – C 61/60 Mn 3 – – – C 61 – C 61 – – – 1.0642 – – C 85/85 Mn 3 – – – C 85 – C 85 – – – 1.0647 – – 35 SPb 20 35 SPb 20 – – 35 SPb 20 35 SPb 20 – – – – 1.0756 – – 45 SPb 20 – – – 46 SPb 20 – – – – – 1.0757 – – 38 SMnPb 28 38 SMnPb 28 – – 38 SMnPb 28 38 SMnPb 28 – – – – 1.0761 – – 44 SMn 28 44 SMn 28 – – 44 SMn 28 44 SMn 28 – – – – 1.0762 – – 44 SMnPb 28 44 SMnPb 28 – – 44 SMnPb 28 44 SMnPb 28 – – – – 1.0763 – – 36 SMnPb 14 36 SMnPb 14 – – 36 SMnPb 14 36 SMnPb 14 – – – – 1.0765 – 9255 51 Si 7 250 A 53 – G92550 – 51 S 7 48 Si 7 2090 – – 1.0903 – 9255 55 Si 7 250 A 53 SKH 1; SKT 4 G92550 55 NiCrMoV 7 55 S 7 55 Si 8 2085 – – 1.0904 – – StSch 1100 (R 1100 Cr) – – – R 1100 Cr – – – – – 1.0915 – 9262 60 SiCr 7 250 A 61 SUP 7 G92620 60 SiCr 8 60 SC 7 60 SiCr 8 – – – 1.0961 – – QSt E 690 TM (S 700 MC) – – – S 700 MC S 690 MC S 700 MC – – – 1.0966 – – QSt E 260 N 7 S 260 NC – AE 275 NC – S 260 NC – S 260 NCX – – – 1.0971 – – QSt E 300 TM/S 315 MC 43 F35 HR,HS,CS – – S 315 MC E 315 D S 315 MC – – – 1.0972 – – QSt E 300 N 7/S 315 NC – AE 340 NC – S 315 NC – S 315 NC – – – 1.0973 – – QSt E340 TM HR 40/30 – – S 340 MC E 335 D – – – – 1.0974 – – QSt E340 N – – – S 340 NC – Fe E 355 TD – – – 1.0975 – – QSt E 360TM – – – S 355 MC E 355 D Fe E 355 TM – – – 1.0976 – – QSt E360 N – – – S 355 NC – Fe E 355 TD – – – 1.0977 – – QSt E380 TM – – – S 380 MC E 390 D – – – – 1.0978 – – QSt E380 N – – – S 380 NC – Fe E 380 TD – – – 1.0979 – – QSt E420 TM HR 50 F 45 – – S 420 MC E 430 D Fe E 420 TM – – – 1.0980 – – QSt E 420 N – – – S 420 NC – Fe E 420 TD – – – 1.0981 – – QSt E 460 TM 50/45 HR – – S 460 MC E 445 D – – – – 1.0982 – – QSt E 460 N – – – S 460 NC – Fe E 460 TD – – – 1.0983 – – QSt E500 TM – – – S 500 MC E 490 D Fe E 490 TM 2662 – – 1.0984 – – QSt E500 N – – – S 500 NC – – – – – 1.0985 – – QSt E550 TM 60/55 HS – – S 550 MC E 560 D Fe E 560 TM – – – 1.0986 – – QSt E550 N – – – S 550 NC – – – – – 1.0987 – – FStE 355 OS 3/S355G04 – – – S 355 G04 – – – – – 1.1102 – – EStE 285 P 275 NL 2 STK 400 – P 275 NL 2 P 275 NL 2 P 275 NL 2 – – – 1.1104 – – EStE 315 – – – S 315 NL 1 – – – – – 1.1105 – – EStE 355 P 355 NL 2 STK 500 – P 355 NL 2 P 355 NL 2 P 355 NL 2 – – – 1.1106 – – C5D2 – – – C5D2 FM 6 C5D2 – – – 1.1111 – – USD 5/C 8 E1 W – – – C8E1W – – – – – 1.1112 – – C8D2 – – – C8D2 FM 8 C8D2 – – – 1.1113 – – C 10 E W/RSD 11 – – – C 10 EW – – – – – 1.1115 – – USD 6/C 8 E2 W – – – C8E2W – – – – – 1.1116 – – G 24 Mn 4/GS 24 Mn 4 – – – G 24 Mn 4 – – – – – 1.1136 – – C32D2 – – – C 32 D 2 FM 32 C 32 D 2 – – – 1.1143 – – C36D2 – – – C 36 D 2 FM 36 C 36 D 2 – – – 1.1145 – – C38D2 – – – C 38 D 2 FM 38 C 38 D 2 – – – 1.1150 – – C 25 R C 25 R – – C 25 R C 25 R C 25 R – – – 1.1163 – – C48D2 – – – C 48 D 2 FM 48 C48 D 2 – – – 1.1164 – 1330 GS–30 Mn 5 120 M 36 SMn 433 H; SCMn 2 K13300 – 35 M 5 – 1330 – – 1.1165 – 1335 36 Mn 5 150 M 36 SMn 438(H) G13350 – 40 M 5 – 2120 – – 1.1167 – – G 40 Mn 5/GS 40 Mn 5 – – – G 40 Mn 5 – – – – – 1.1168 – – 20 Mn 6 150 M 19 – – – 20 M 5 20 Mn 6 – – – 1.1169 – – C50D2 – – – C 50 D 2 FM 50 C50D 2 – – – 1.1171 – – Ck 38 Pb – – – 25 Mn 4 – – – – – 1.1177 – – C 30 R C 30 R C 30 R ( 3 C 30) – C 30 R C 30 R C 30 R – – – 1.1179 – – Ck 35 Pb – – – S 355 G 13 – – – – – 1.1182 – – Ck 36 – – – S 355 G 14 – – – – – 1.1184 – – C3D1 – – – C3D1 – C3D1 – – – 1.1187 – – C40R/Cm 40 C 40 R – – C 40 R C 40 R C 40 – – – 1.1189 – – C52D2 – – – C 52 D 2 FM 52 C 52 D 2 – – – 1.1202 – – C 53 R/Cm 53 – – – C 53 R – – – – – 1.1205 – – C 10 R C 10 R – – C 10 R C 10 R – – – – 1.1207 – – C 16 R C 16 R – – C 16 R C 16 R – – – – 1.1208 – – C58D2 – – – C 58 D 2 FM 58 C 58 D 2 – – – 1.1212 – – Ck 53 Pb – – – C 90 S – – – – – 1.1217 – – C62D2 – – – C 62 D 2 FM 62 C 62 D 2 – – – 1.1222 – – Cm 60 C 60 R – – 3 C 60 C 60 R C 60 R – – – 1.1223 – – C60D2 – – – C 60 D 2 FM 60 C 60 D 2 – – – 1.1228 – – C68D2 – – – C 68 D 2 FM 68 C 68 D 2 – – – 1.1232 – – C66D2 – – – C 66 D 2 FM 66 C 66 D 2 – – – 1.1236 – – C50R C 50 R – – C 50 R FM 50 C 50 R – – – 1.1241 – – C72D2 – – – C 72 D 2 FM 72 C 72 D 2 – – – 1.1242 – – C70D2 – – – C 70 D 2 FM 70 C 70 D 2 – – – 1.1251 – – C78D2 – – – C 78 D 2 FM 78 C 78 D 2 – – – 1.1252 – – C76D2 – – – C 76 D 2 FM 76 C 76 D 2 – – – 1.1253 – – C80D2 – – – C 80 D 2 FM 80 C 80 D 2 – – – 1.1255 – – C82D2 – – – C 82 D 2 FM 82 C 82 D 2 – – – 1.1262 – – C86D2 – – – C 86 D 2 FM 86 C 86 D 2 – – – 1.1265 – – C88D2 – – – C 88 D 2 – C 88 D 2 – – – 1.1272 – – C92D2 – – – C 92 D 2 – C 92 D 2 – – – 1.1282 – – C98D2 – – – C 98 D 2 – C 98 D 2 – – – 1.1283 – – 46 MnVS 6 – – – 46 MnVS 6 – – – – – 1.1304 – – C 90 U – – – C90U – – – – – 1.1535 – – C 110 W – – – C 110 U – – – – – 1.1554 – – C 120 U – – – C120U – – – – – 1.1555 – T8 C 80 W2 BW 1B SKC 3 T12008 – Y1 80 C 80 KU – – – 1.1625 – – C 105 W2 – SK 3 – – – – – – – 1.1645 – – C 135 W – SK 1 – – Y2 140 C 140 KU – – – 1.1673 – A-6 C 67 W – – T30106 – Y1 70 – – – – 1.1744 – (продолжение) Y200 kennametal.com

Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1 Каталог Kennametal инновации 2020.2

Каталог Kennametal инновации 2020.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Основной каталог Kennametal вращающиеся инструменты 2018

Основной каталог Kennametal вращающиеся инструменты 2018 Каталог Kennametal инновации 2020.1

Каталог Kennametal инновации 2020.1 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2