Основной каталог Kennametal невращающиеся инструменты - страница 965

Навигация

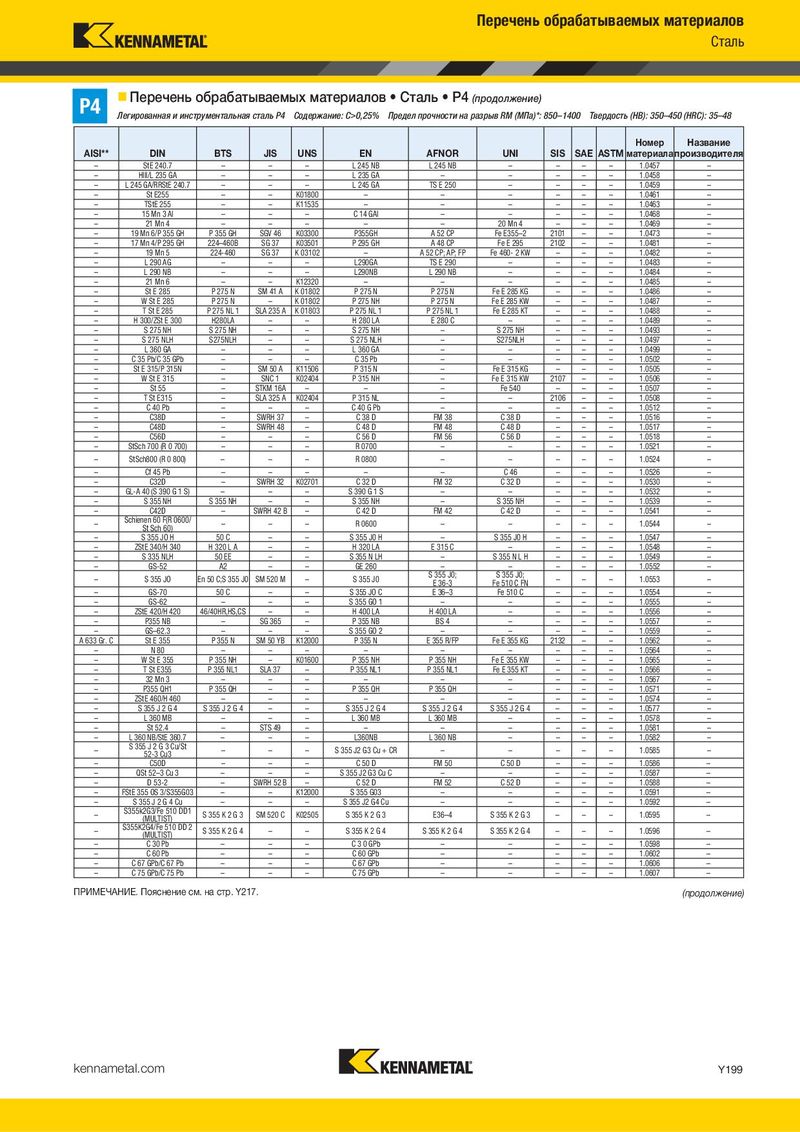

Перечень обрабатываемых материалов Сталь P4 Перечень обрабатываемых материалов • Сталь • P4 (продолжение) Легированная и инструментальная сталь P4 Содержание: C>0,25% Предел прочности на разрыв RM (МПа)*: 850–1400 Твердость (HB): 350–450 (HRC): 35–48 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя – StE 240.7 – – – L 245 NB L 245 NB – – – – 1.0457 – – HIII/L 235 GA – – – L 235 GA – – – – – 1.0458 – – L 245 GA/RRStE 240.7 – – – L 245 GA TS E 250 – – – – 1.0459 – – St E255 – – K01800 – – – – – – 1.0461 – – TStE 255 – – K11535 – – – – – – 1.0463 – – 15 Mn 3 Al – – – C 14 GAl – – – – – 1.0468 – – 21 Mn 4 – – – – – 20 Mn 4 – – – 1.0469 – – 19 Mn 6/P 355 GH P 355 GH SGV 46 K03300 P355GH A 52 CP Fe E355–2 2101 – – 1.0473 – – 17 Mn 4/P 295 GH 224–460B SG 37 K03501 P 295 GH A 48 CP Fe E 295 2102 – – 1.0481 – – 19 Mn 5 224-460 SG 37 K 03102 – A 52 CP; AP; FP Fe 460- 2 KW – – – 1.0482 – – L 290 AG – – – L290GA TS E 290 – – – – 1.0483 – – L 290 NB – – – L290NB L 290 NB – – – – 1.0484 – – 21 Mn 6 – – K12320 – – – – – – 1.0485 – – St E 285 P 275 N SM 41 A K 01802 P 275 N P 275 N Fe E 285 KG – – – 1.0486 – – W St E 285 P 275 N – K 01802 P 275 NH P 275 N Fe E 285 KW – – – 1.0487 – – T St E 285 P 275 NL 1 SLA 235 A K 01803 P 275 NL 1 P 275 NL 1 Fe E 285 KT – – – 1.0488 – – H 300/ZSt E 300 H280LA – – H 280 LA E 280 C – – – – 1.0489 – – S 275 NH S 275 NH – – S 275 NH – S 275 NH – – – 1.0493 – – S 275 NLH S275NLH – – S 275 NLH – S275NLH – – – 1.0497 – – L 360 GA – – – L 360 GA – – – – – 1.0499 – – C 35 Pb/C 35 GPb – – – C 35 Pb – – – – – 1.0502 – – St E 315/P 315N – SM 50 A K11506 P 315 N – Fe E 315 KG – – – 1.0505 – – W St E 315 – SNC 1 K02404 P 315 NH – Fe E 315 KW 2107 – – 1.0506 – – St 55 – STKM 16A – – – Fe 540 – – – 1.0507 – – T St E315 – SLA 325 A K02404 P 315 NL – – 2106 – – 1.0508 – – C 40 Pb – – – C 40 G Pb – – – – – 1.0512 – – C38D – SWRH 37 – C 38 D FM 38 C 38 D – – – 1.0516 – – C48D – SWRH 48 – C 48 D FM 48 C 48 D – – – 1.0517 – – C56D – – – C 56 D FM 56 C 56 D – – – 1.0518 – – StSch 700 (R 0 700) – – – R 0700 – – – – – 1.0521 – – StSch800 (R 0 800) – – – R 0800 – – – – – 1.0524 – – Cf 45 Pb – – – – – C 46 – – – 1.0526 – – C32D – SWRH 32 K02701 C 32 D FM 32 C 32 D – – – 1.0530 – – GL-A 40 (S 390 G 1 S) – – – S 390 G 1 S – – – – – 1.0532 – – S 355 NH S 355 NH – – S 355 NH – S 355 NH – – – 1.0539 – – C42D – SWRH 42 B – C 42 D FM 42 C 42 D – – – 1.0541 – – Schienen 60 F(R 0600/ – – – R 0600 – – – – – 1.0544 – St Sch 60) – S 355 JO H 50 C – – S 355 J0 H – S 355 J0 H – – – 1.0547 – – ZStE 340/H 340 H 320 L A – – H 320 LA E 315 C – – – – 1.0548 – – S 335 NLH 50 EE – – S 355 N LH – S 355 N L H – – – 1.0549 – – GS-52 A2 – – GE 260 – – – – – 1.0552 – – S 355 JO En 50 C;S 355 J0 SM 520 M – S 355 J0 S 355 J0; S 355 J0; – – – 1.0553 – E 36-3 Fe 510 C FN – GS-70 50 C – – S 355 JO C E 36–3 Fe 510 C – – – 1.0554 – – GS-62 – – – S 355 GO 1 – – – – – 1.0555 – – ZStE 420/H 420 46/40HR,HS,CS – – H 400 LA H 400 LA – – – – 1.0556 – – P355 NB – SG 365 – P 355 NB BS 4 – – – – 1.0557 – – GS–62.3 – – – S 355 GO 2 – – – – – 1.0559 – A 633 Gr. C St E 355 P 355 N SM 50 YB K12000 P 355 N E 355 R/FP Fe E 355 KG 2132 – – 1.0562 – – N 80 – – – – – – – – – 1.0564 – – W St E 355 P 355 NH – K01600 P 355 NH P 355 NH Fe E 355 KW – – – 1.0565 – – T St E355 P 355 NL1 SLA 37 – P 355 NL1 P 355 NL1 Fe E 355 KT – – – 1.0566 – – 32 Mn 3 – – – – – – – – – 1.0567 – – P355 QH1 P 355 QH – – P 355 QH P 355 QH – – – – 1.0571 – – ZStE 460/H 460 – – – – – – – – – 1.0574 – – S 355 J 2 G 4 S 355 J 2 G 4 – – S 355 J 2 G 4 S 355 J 2 G 4 S 355 J 2 G 4 – – – 1.0577 – – L 360 MB – – – L 360 MB L 360 MB – – – – 1.0578 – – St 52.4 – STS 49 – – – – – – – 1.0581 – – L 360 NB/StE 360.7 – – – L360NB L 360 NB – – – – 1.0582 – – S 355 J 2 G 3 Cu/St – – – S 355 J2 G3 Cu + CR – – – – – 1.0585 – 52-3 Cu3 – C50D – – – C 50 D FM 50 C 50 D – – – 1.0586 – – QSt 52–3 Cu 3 – – – S 355 J2 G3 Cu C – – – – – 1.0587 – – D 53-2 – SWRH 52 B – C 52 D FM 52 C 52 D – – – 1.0588 – – FStE 355 OS 3/S355G03 – – K12000 S 355 G03 – – – – – 1.0591 – – S 355 J 2 G 4 Cu – – – S 355 J2 G4 Cu – – – – – 1.0592 – – S355k2G3/Fe 510 DD1 S 355 K 2 G 3 SM 520 C K02505 S 355 K 2 G 3 E36–4 S 355 K 2 G 3 – – – 1.0595 – (MULTIST) – S355K2G4/Fe 510 DD 2 S 355 K 2 G 4 – – S 355 K 2 G 4 S 355 K 2 G 4 S 355 K 2 G 4 – – – 1.0596 – (MULTIST) – C 30 Pb – – – C 3 0 GPb – – – – – 1.0598 – – C 60 Pb – – – C 60 GPb – – – – – 1.0602 – – C 67 GPb/C 67 Pb – – – C 67 GPb – – – – – 1.0606 – – C 75 GPb/C 75 Pb – – – C 75 GPb – – – – – 1.0607 – ПРИМЕЧАНИЕ. Пояснение см. на стр. Y217. (продолжение) kennametal.com Y199

Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1 Каталог Kennametal инновации 2020.2

Каталог Kennametal инновации 2020.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Основной каталог Kennametal вращающиеся инструменты 2018

Основной каталог Kennametal вращающиеся инструменты 2018 Каталог Kennametal инновации 2020.1

Каталог Kennametal инновации 2020.1 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2