Основной каталог Kennametal невращающиеся инструменты - страница 964

Навигация

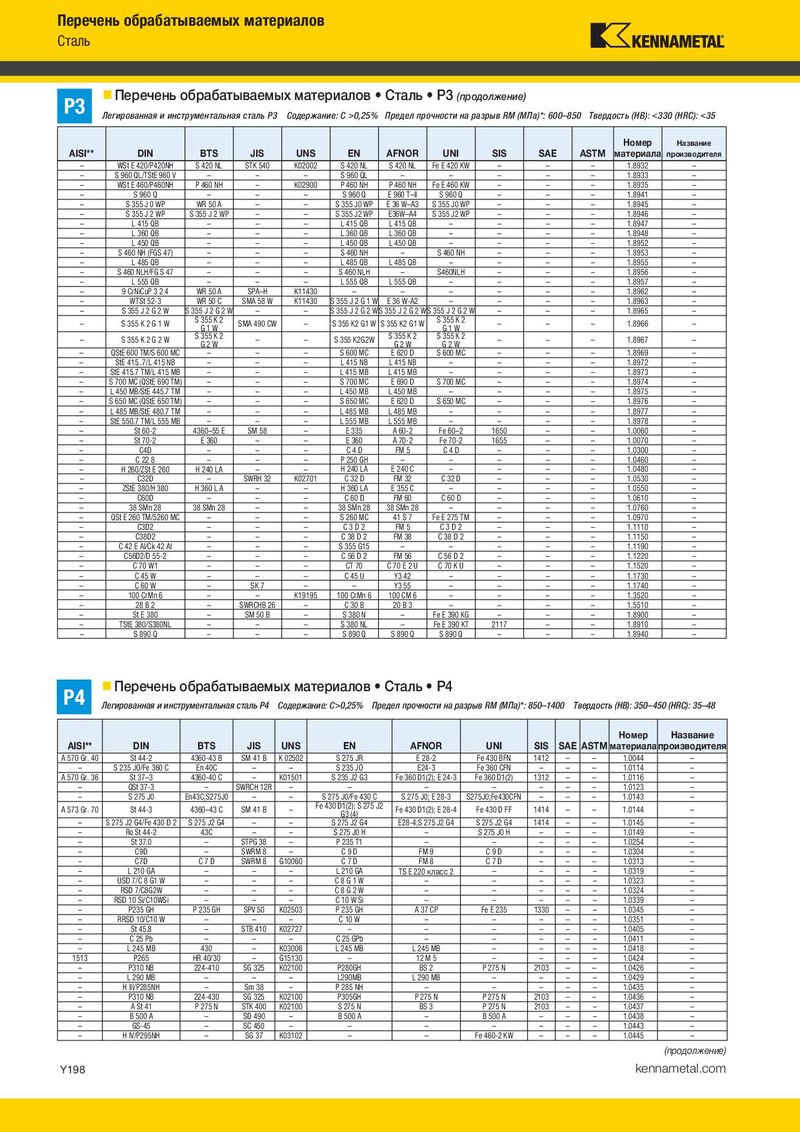

Перечень обрабатываемых материалов Сталь P3 Перечень обрабатываемых материалов • Сталь • P3 (продолжение) Легированная и инструментальная сталь P3 Содержание: C >0,25% Предел прочности на разрыв RM (МПа)*: 600–850 Твердость (HB): <330 (HRC): <35 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя – WSt E 420/P420NH S 420 NL STK 540 K02002 S 420 NL S 420 NL Fe E 420 KW – – – 1.8932 – – S 960 QL/TStE 960 V – – – S 960 QL – – – – – 1.8933 – – WSt E 460/P460NH P 460 NH – K02900 P 460 NH P 460 NH Fe E 460 KW – – – 1.8935 – – S 960 Q – – – S 960 Q E 960 T–II S 960 Q – – – 1.8941 – – S 355 J 0 WP WR 50 A – – S 355 J0 WP E 36 W–A3 S 355 J0 WP – – – 1.8945 – – S 355 J 2 WP S 355 J 2 WP – – S 355 J2 WP E36W–A4 S 355 J2 WP – – – 1.8946 – – L 415 QB – – – L 415 QB L 415 QB – – – – 1.8947 – – L 360 QB – – – L 360 QB L 360 QB – – – – 1.8948 – – L 450 QB – – – L 450 QB L 450 QB – – – – 1.8952 – – S 460 NH (FGS 47) – – – S 460 NH – S 460 NH – – – 1.8953 – – L 485 QB – – – L 485 QB L 485 QB – – – – 1.8955 – – S 460 NLH/FG S 47 – – – S 460 NLH – S460NLH – – – 1.8956 – – L 555 QB – – – L 555 QB L 555 QB – – – – 1.8957 – – 9 CrNiCuP 3 2 4 WR 50 A SPA–H K11430 – – – – – – 1.8962 – – WTSt 52-3 WR 50 C SMA 58 W K11430 S 355 J 2 G 1 W E 36 W-A2 – – – – 1.8963 – – S 355 J 2 G 2 W S 355 J 2 G 2 W – – S 355 J 2 G 2 W S 355 J 2 G 2 W S 355 J 2 G 2 W – – – 1.8965 – – S 355 K 2 G 1 W S 355 K 2 SMA 490 CW – S 355 K2 G1 W S 355 K2 G1 W S 355 K 2 – – – 1.8966 – G1W G1W – S 355 K 2 G 2 W S 355 K 2 – – S 355 K2G2W S 355 K 2 S 355 K 2 – – – 1.8967 – G2W G2W G2W – QStE 600 TM/S 600 MC – – – S 600 MC E 620 D S 600 MC – – – 1.8969 – – StE 415..7/L 415 NB – – – L 415 NB L 415 NB – – – – 1.8972 – – StE 415.7 TM/L 415 MB – – – L 415 MB L 415 MB – – – – 1.8973 – – S 700 MC (QStE 690 TM) – – – S 700 MC E 690 D S 700 MC – – – 1.8974 – – L 450 MB/StE 445.7 TM – – – L 450 MB L 450 MB – – – – 1.8975 – – S 650 MC (QStE 650 TM) – – – S 650 MC E 620 D S 650 MC – – – 1.8976 – – L 485 MB/StE 480.7 TM – – – L 485 MB L 485 MB – – – – 1.8977 – – StE 550.7 TM/L 555 MB – – – L 555 MB L 555 MB – – – – 1.8978 – – St 60-2 4360–55 E SM 58 – E 335 A 60-2 Fe 60–2 1650 – – 1.0060 – – St 70-2 E 360 – – E 360 A 70-2 Fe 70-2 1655 – – 1.0070 – – C4D – – – C4D FM 5 C4D – – – 1.0300 – – C 22 8 – – – P 250 GH – – – – – 1.0460 – – H 260/ZSt E 260 H 240 LA – – H 240 LA E 240 C – – – – 1.0480 – – C32D – SWRH 32 K02701 C 32 D FM 32 C 32 D – – – 1.0530 – – ZStE 380/H 380 H 360 L A – – H 360 LA E 355 C – – – – 1.0550 – – C60D – – – C 60 D FM 60 C 60 D – – – 1.0610 – – 38 SMn 28 38 SMn 28 – – 38 SMn 28 38 SMn 28 – – – – 1.0760 – – QSt E 260 TM/5260 MC – – – S 260 MC 41 S 7 Fe E 275 TM – – – 1.0970 – – C3D2 – – – C3D2 FM 5 C3D2 – – – 1.1110 – – C38D2 – – – C 38 D 2 FM 38 C 38 D 2 – – – 1.1150 – – C 42 E Al/Ck 42 Al – – – S 355 G15 – – – – – 1.1190 – – C56D2/D 55-2 – – – C 56 D 2 FM 56 C 56 D 2 – – – 1.1220 – – C 70 W1 – – – CT 70 C 70 E 2 U C 70 K U – – – 1.1520 – – C 45 W – – – C 45 U Y3 42 – – – – 1.1730 – – C 60 W – SK 7 – – Y3 55 – – – – 1.1740 – – 100 CrMn 6 – – K19195 100 CrMn 6 100 CM 6 – – – – 1.3520 – – 28 B 2 – SWRCHB 26 – C 30 B 20 B 3 – – – – 1.5510 – – St E 380 – SM 50 B – S 380 N – Fe E 390 KG – – – 1.8900 – – TStE 380/S380NL – – – S 380 NL – Fe E 390 KT 2117 – – 1.8910 – – S 890 Q – – – S 890 Q S 890 Q S 890 Q – – – 1.8940 – P4 Перечень обрабатываемых материалов • Сталь • P4 Легированная и инструментальная сталь P4 Содержание: C>0,25% Предел прочности на разрыв RM (МПа)*: 850–1400 Твердость (HB): 350–450 (HRC): 35–48 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя A 570 Gr. 40 St 44-2 4360-43 B SM 41 B K 02502 S 275 JR E 28-2 Fe 430 BFN 1412 – – 1.0044 – – S 235 JO/Fe 360 C En 40C – – S 235 JO E24-3 Fe 360 CFN – – – 1.0114 – A 570 Gr. 36 St 37–3 4360-40 C – K01501 S 235 J2 G3 Fe 360 D1(2); E 24-3 Fe 360 D1(2) 1312 – – 1.0116 – – QSt 37-3 – SWRCH 12R – – – – – – – 1.0123 – – S 275 J0 En43C;S275J0 – – S 275 J0/Fe 430 C S 275 J0; E 28-3 S275J0;Fe430CFN – – – 1.0143 – A 573 Gr. 70 St 44-3 4360–43 C SM 41 B – Fe 430 D1(2); S 275 J2 Fe 430 D1(2); E 28-4 Fe 430 D FF 1414 – – 1.0144 – G3 (4) – S 275 J2 G4/Fe 430 D 2 S 275 J2 G4 – – S 275 J2 G4 E28-4;S 275 J2 G4 S 275 J2 G4 1414 – – 1.0145 – – Ro St 44-2 43C – – S 275 J0 H – S 275 J0 H – – – 1.0149 – – St 37.0 – STPG 38 – P 235 T1 – – – – – 1.0254 – – C9D – SWRM 8 – C9D FM 9 C9D – – – 1.0304 – – C7D C7D SWRM 8 G10060 C7D FM 8 C7D – – – 1.0313 – – L 210 GA – – – L 210 GA TS E 220 класс 2 – – – – 1.0319 – – USD 7/C 8 G1 W – – – C8G1W – – – – – 1.0323 – – RSD 7/C8G2W – – – C8G2W – – – – – 1.0324 – – RSD 10 Si/C10WSi – – – C 10 W Si – – – – – 1.0339 – – P235 GH P 235 GH SPV 50 K02503 P 235 GH A 37 CP Fe E 235 1330 – – 1.0345 – – RRSD 10/C10 W – – – C 10 W – – – – – 1.0351 – – St 45.8 – STB 410 K02727 – – – – – – 1.0405 – – C 25 Pb – – – C 25 GPb – – – – – 1.0411 – – L 245 MB 430 – K03006 L 245 MB L 245 MB – – – – 1.0418 – 1513 P265 HR 40/30 – G15130 – 12 M 5 – – – – 1.0424 – – P310 NB 224-410 SG 325 K02100 P280GH BS 2 P 275 N 2103 – – 1.0426 – – L 290 MB – – – L290MB L 290 MB – – – – 1.0429 – – H III/P285NH – Sm 38 – P 285 NH – – – – – 1.0435 – – P310 NB 224-430 SG 325 K02100 P305GH P 275 N P 275 N 2103 – – 1.0436 – – A St 41 P 275 N STK 400 K02100 S 275 N BS 3 P 275 N 2103 – – 1.0437 – – B 500 A – SD 490 – B 500 A – B 500 A – – – 1.0438 – – GS-45 – SC 450 – – – – – – – 1.0443 – – H IV/P295NH – SG 37 K03102 – – Fe 460-2 KW – – – 1.0445 – (продолжение) Y198 kennametal.com

Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1 Каталог Kennametal инновации 2020.2

Каталог Kennametal инновации 2020.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Основной каталог Kennametal вращающиеся инструменты 2018

Основной каталог Kennametal вращающиеся инструменты 2018 Каталог Kennametal инновации 2020.1

Каталог Kennametal инновации 2020.1 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2