Основной каталог Kennametal невращающиеся инструменты - страница 963

Навигация

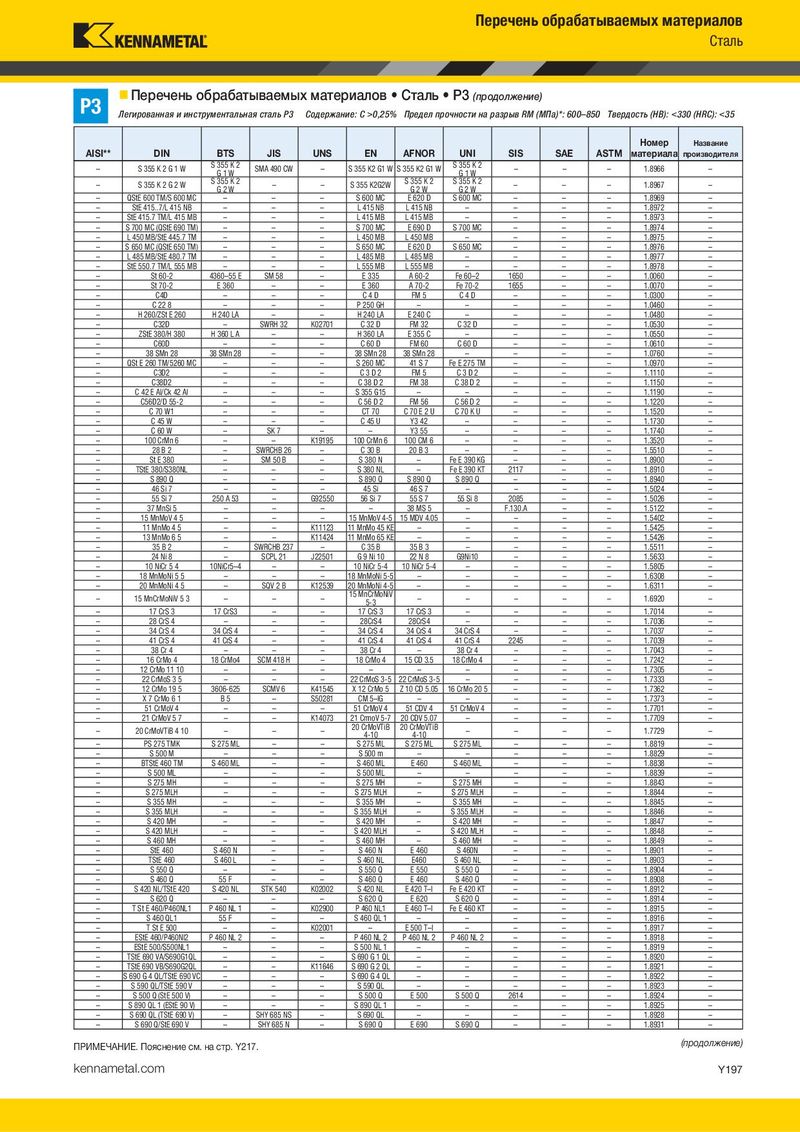

Перечень обрабатываемых материалов Сталь P3 Перечень обрабатываемых материалов • Сталь • P3 (продолжение) Легированная и инструментальная сталь P3 Содержание: C >0,25% Предел прочности на разрыв RM (МПа)*: 600–850 Твердость (HB): <330 (HRC): <35 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя – S 355 K 2 G 1 W S 355 K 2 SMA 490 CW – S 355 K2 G1 W S 355 K2 G1 W S 355 K 2 – – – 1.8966 – G1W G1W – S 355 K 2 G 2 W S 355 K 2 – – S 355 K2G2W S 355 K 2 S 355 K 2 – – – 1.8967 – G2W G2W G2W – QStE 600 TM/S 600 MC – – – S 600 MC E 620 D S 600 MC – – – 1.8969 – – StE 415..7/L 415 NB – – – L 415 NB L 415 NB – – – – 1.8972 – – StE 415.7 TM/L 415 MB – – – L 415 MB L 415 MB – – – – 1.8973 – – S 700 MC (QStE 690 TM) – – – S 700 MC E 690 D S 700 MC – – – 1.8974 – – L 450 MB/StE 445.7 TM – – – L 450 MB L 450 MB – – – – 1.8975 – – S 650 MC (QStE 650 TM) – – – S 650 MC E 620 D S 650 MC – – – 1.8976 – – L 485 MB/StE 480.7 TM – – – L 485 MB L 485 MB – – – – 1.8977 – – StE 550.7 TM/L 555 MB – – – L 555 MB L 555 MB – – – – 1.8978 – – St 60-2 4360–55 E SM 58 – E 335 A 60-2 Fe 60–2 1650 – – 1.0060 – – St 70-2 E 360 – – E 360 A 70-2 Fe 70-2 1655 – – 1.0070 – – C4D – – – C4D FM 5 C4D – – – 1.0300 – – C 22 8 – – – P 250 GH – – – – – 1.0460 – – H 260/ZSt E 260 H 240 LA – – H 240 LA E 240 C – – – – 1.0480 – – C32D – SWRH 32 K02701 C 32 D FM 32 C 32 D – – – 1.0530 – – ZStE 380/H 380 H 360 L A – – H 360 LA E 355 C – – – – 1.0550 – – C60D – – – C 60 D FM 60 C 60 D – – – 1.0610 – – 38 SMn 28 38 SMn 28 – – 38 SMn 28 38 SMn 28 – – – – 1.0760 – – QSt E 260 TM/5260 MC – – – S 260 MC 41 S 7 Fe E 275 TM – – – 1.0970 – – C3D2 – – – C3D2 FM 5 C3D2 – – – 1.1110 – – C38D2 – – – C 38 D 2 FM 38 C 38 D 2 – – – 1.1150 – – C 42 E Al/Ck 42 Al – – – S 355 G15 – – – – – 1.1190 – – C56D2/D 55-2 – – – C 56 D 2 FM 56 C 56 D 2 – – – 1.1220 – – C 70 W1 – – – CT 70 C 70 E 2 U C 70 K U – – – 1.1520 – – C 45 W – – – C 45 U Y3 42 – – – – 1.1730 – – C 60 W – SK 7 – – Y3 55 – – – – 1.1740 – – 100 CrMn 6 – – K19195 100 CrMn 6 100 CM 6 – – – – 1.3520 – – 28 B 2 – SWRCHB 26 – C 30 B 20 B 3 – – – – 1.5510 – – St E 380 – SM 50 B – S 380 N – Fe E 390 KG – – – 1.8900 – – TStE 380/S380NL – – – S 380 NL – Fe E 390 KT 2117 – – 1.8910 – – S 890 Q – – – S 890 Q S 890 Q S 890 Q – – – 1.8940 – – 46 Si 7 – – – 45 Si 46 S 7 – – – – 1.5024 – – 55 Si 7 250 A 53 – G92550 56 Si 7 55 S 7 55 Si 8 2085 – – 1.5026 – – 37 MnSi 5 – – – – 38 MS 5 – F.130.A – – 1.5122 – – 15 MnMoV 4 5 – – – 15 MnMoV 4-5 15 MDV 4.05 – – – – 1.5402 – – 11 MnMo 4 5 – – K11123 11 MnMo 45 KE – – – – – 1.5425 – – 13 MnMo 6 5 – – K11424 11 MnMo 65 KE – – – – – 1.5426 – – 35 B 2 – SWRCHB 237 – C 35 B 35 B 3 – – – – 1.5511 – – 24 Ni 8 – SCPL 21 J22501 G 9 Ni 10 22 N 8 G9Ni10 – – – 1.5633 – – 10 NiCr 5 4 10NiCr5–4 – – 10 NiCr 5-4 10 NiCr 5-4 – – – – 1.5805 – – 18 MnMoNi 5 5 – – – 18 MnMoNi 5-5 – – – – – 1.6308 – – 20 MnMoNi 4 5 – SQV 2 B K12539 20 MnMoNi 4-5 – – – – – 1.6311 – – 15 MnCrMoNiV 5 3 – – – 15 MnCrMoNiV – – – – – 1.6920 – 5-3 – 17 CrS 3 17 CrS3 – – 17 CrS 3 17 CrS 3 – – – – 1.7014 – – 28 CrS 4 – – – 28CrS4 28CrS4 – – – – 1.7036 – – 34 CrS 4 34 CrS 4 – – 34 CrS 4 34 CrS 4 34 CrS 4 – – – 1.7037 – – 41 CrS 4 41 CrS 4 – – 41 CrS 4 41 CrS 4 41 CrS 4 2245 – – 1.7039 – – 38 Cr 4 – – – 38 Cr 4 – 38 Cr 4 – – – 1.7043 – – 16 CrMo 4 18 CrMo4 SCM 418 H – 18 CrMo 4 15 CD 3.5 18 CrMo 4 – – – 1.7242 – – 12 CrMo 11 10 – – – – – – – – – 1.7305 – – 22 CrMoS 3 5 – – – 22 CrMoS 3-5 22 CrMoS 3-5 – – – – 1.7333 – – 12 CrMo 19 5 3606-625 SCMV 6 K41545 X 12 CrMo 5 Z 10 CD 5.05 16 CrMo 20 5 – – – 1.7362 – – X 7 CrMo 6 1 B5 – S50281 CM 5–IG – – – – – 1.7373 – – 51 CrMoV 4 – – – 51 CrMoV 4 51 CDV 4 51 CrMoV 4 – – – 1.7701 – – 21 CrMoV 5 7 – – K14073 21 CrmoV 5-7 20 CDV 5.07 – – – – 1.7709 – – 20 CrMoVTiB 4 10 – – – 20 CrMoVTiB 20 CrMoVTiB – – – – 1.7729 – 4-10 4-10 – PS 275 TMK S 275 ML – – S 275 ML S 275 ML S 275 ML – – – 1.8819 – – S 500 M – – – S 500 m – – – – – 1.8829 – – BTStE 460 TM S 460 ML – – S 460 ML E 460 S 460 ML – – – 1.8838 – – S 500 ML – – – S 500 ML – – – – – 1.8839 – – S 275 MH – – – S 275 MH – S 275 MH – – – 1.8843 – – S 275 MLH – – – S 275 MLH – S 275 MLH – – – 1.8844 – – S 355 MH – – – S 355 MH – S 355 MH – – – 1.8845 – – S 355 MLH – – – S 355 MLH – S 355 MLH – – – 1.8846 – – S 420 MH – – – S 420 MH – S 420 MH – – – 1.8847 – – S 420 MLH – – – S 420 MLH – S 420 MLH – – – 1.8848 – – S 460 MH – – – S 460 MH – S 460 MH – – – 1.8849 – – StE 460 S 460 N – – S 460 N E 460 S 460N – – – 1.8901 – – TStE 460 S 460 L – – S 460 NL E460 S 460 NL – – – 1.8903 – – S 550 Q – – – S 550 Q E 550 S 550 Q – – – 1.8904 – – S 460 Q 55 F – – S 460 Q E 460 S 460 Q – – – 1.8908 – – S 420 NL/TStE 420 S 420 NL STK 540 K02002 S 420 NL E 420 T–I Fe E 420 KT – – – 1.8912 – – S 620 Q – – – S 620 Q E 620 S 620 Q – – – 1.8914 – – T St E 460/P460NL1 P 460 NL 1 – K02900 P 460 NL1 E 460 T–I Fe E 460 KT – – – 1.8915 – – S 460 QL1 55 F – – S 460 QL 1 – – – – – 1.8916 – – T St E 500 – – K02001 – E 500 T–I – – – – 1.8917 – – EStE 460/P460Nl2 P 460 NL 2 – – P 460 NL 2 P 460 NL 2 P 460 NL 2 – – – 1.8918 – – EStE 500/S500NL1 – – – S 500 NL 1 – – – – – 1.8919 – – TStE 690 VA/S690G1QL – – – S 690 G 1 QL – – – – – 1.8920 – – TStE 690 VB/S690G2QL – – K11646 S 690 G 2 QL – – – – – 1.8921 – – S 690 G 4 QL/TStE 690 VC – – – S 690 G 4 QL – – – – – 1.8922 – – S 590 QL/TStE 590 V – – – S 590 QL – – – – – 1.8923 – – S 500 Q (StE 500 V) – – – S 500 Q E 500 S 500 Q 2614 – – 1.8924 – – S 890 QL 1 (EStE 90 V) – – – S 890 QL 1 – – – – – 1.8925 – – S 690 QL (TStE 690 V) – SHY 685 NS – S 690 QL – – – – – 1.8928 – – S 690 Q/StE 690 V – SHY 685 N – S 690 Q E 690 S 690 Q – – – 1.8931 – ПРИМЕЧАНИЕ. Пояснение см. на стр. Y217. (продолжение) kennametal.com Y197

Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1 Каталог Kennametal инновации 2020.2

Каталог Kennametal инновации 2020.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Основной каталог Kennametal вращающиеся инструменты 2018

Основной каталог Kennametal вращающиеся инструменты 2018 Каталог Kennametal инновации 2020.1

Каталог Kennametal инновации 2020.1 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2