Основной каталог Kennametal невращающиеся инструменты - страница 962

Навигация

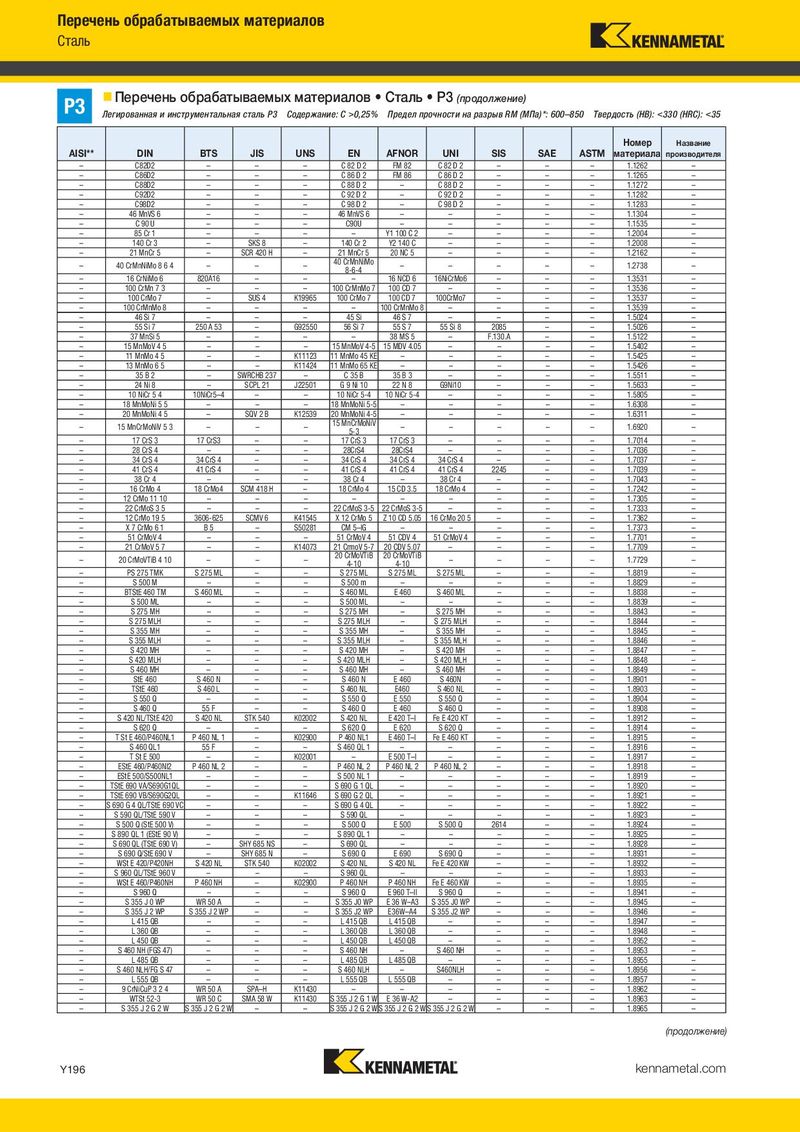

Перечень обрабатываемых материалов Сталь P3 Перечень обрабатываемых материалов • Сталь • P3 (продолжение) Легированная и инструментальная сталь P3 Содержание: C >0,25% Предел прочности на разрыв RM (МПа)*: 600–850 Твердость (HB): <330 (HRC): <35 Номер Название AISI** DIN BTS JIS UNS EN AFNOR UNI SIS SAE ASTM материала производителя – C82D2 – – – C 82 D 2 FM 82 C 82 D 2 – – – 1.1262 – – C86D2 – – – C 86 D 2 FM 86 C 86 D 2 – – – 1.1265 – – C88D2 – – – C 88 D 2 – C 88 D 2 – – – 1.1272 – – C92D2 – – – C 92 D 2 – C 92 D 2 – – – 1.1282 – – C98D2 – – – C 98 D 2 – C 98 D 2 – – – 1.1283 – – 46 MnVS 6 – – – 46 MnVS 6 – – – – – 1.1304 – – C 90 U – – – C90U – – – – – 1.1535 – – 85 Cr 1 – – – – Y1 100 C 2 – – – – 1.2004 – – 140 Cr 3 – SKS 8 – 140 Cr 2 Y2 140 C – – – – 1.2008 – – 21 MnCr 5 – SCR 420 H – 21 MnCr 5 20 NC 5 – – – – 1.2162 – – 40 CrMnNiMo 8 6 4 – – – 40 CrMnNiMo – – – – – 1.2738 – 8-6-4 – 16 CrNiMo 6 820A16 – – – 16 NCD 6 16NiCrMo6 – – – 1.3531 – – 100 CrMn 7 3 – – – 100 CrMnMo 7 100 CD 7 – – – – 1.3536 – – 100 CrMo 7 – SUS 4 K19965 100 CrMo 7 100 CD 7 100CrMo7 – – – 1.3537 – – 100 CrMnMo 8 – – – – 100 CrMnMo 8 – – – – 1.3539 – – 46 Si 7 – – – 45 Si 46 S 7 – – – – 1.5024 – – 55 Si 7 250 A 53 – G92550 56 Si 7 55 S 7 55 Si 8 2085 – – 1.5026 – – 37 MnSi 5 – – – – 38 MS 5 – F.130.A – – 1.5122 – – 15 MnMoV 4 5 – – – 15 MnMoV 4-5 15 MDV 4.05 – – – – 1.5402 – – 11 MnMo 4 5 – – K11123 11 MnMo 45 KE – – – – – 1.5425 – – 13 MnMo 6 5 – – K11424 11 MnMo 65 KE – – – – – 1.5426 – – 35 B 2 – SWRCHB 237 – C 35 B 35 B 3 – – – – 1.5511 – – 24 Ni 8 – SCPL 21 J22501 G 9 Ni 10 22 N 8 G9Ni10 – – – 1.5633 – – 10 NiCr 5 4 10NiCr5–4 – – 10 NiCr 5-4 10 NiCr 5-4 – – – – 1.5805 – – 18 MnMoNi 5 5 – – – 18 MnMoNi 5-5 – – – – – 1.6308 – – 20 MnMoNi 4 5 – SQV 2 B K12539 20 MnMoNi 4-5 – – – – – 1.6311 – – 15 MnCrMoNiV 5 3 – – – 15 MnCrMoNiV – – – – – 1.6920 – 5-3 – 17 CrS 3 17 CrS3 – – 17 CrS 3 17 CrS 3 – – – – 1.7014 – – 28 CrS 4 – – – 28CrS4 28CrS4 – – – – 1.7036 – – 34 CrS 4 34 CrS 4 – – 34 CrS 4 34 CrS 4 34 CrS 4 – – – 1.7037 – – 41 CrS 4 41 CrS 4 – – 41 CrS 4 41 CrS 4 41 CrS 4 2245 – – 1.7039 – – 38 Cr 4 – – – 38 Cr 4 – 38 Cr 4 – – – 1.7043 – – 16 CrMo 4 18 CrMo4 SCM 418 H – 18 CrMo 4 15 CD 3.5 18 CrMo 4 – – – 1.7242 – – 12 CrMo 11 10 – – – – – – – – – 1.7305 – – 22 CrMoS 3 5 – – – 22 CrMoS 3-5 22 CrMoS 3-5 – – – – 1.7333 – – 12 CrMo 19 5 3606-625 SCMV 6 K41545 X 12 CrMo 5 Z 10 CD 5.05 16 CrMo 20 5 – – – 1.7362 – – X 7 CrMo 6 1 B5 – S50281 CM 5–IG – – – – – 1.7373 – – 51 CrMoV 4 – – – 51 CrMoV 4 51 CDV 4 51 CrMoV 4 – – – 1.7701 – – 21 CrMoV 5 7 – – K14073 21 CrmoV 5-7 20 CDV 5.07 – – – – 1.7709 – – 20 CrMoVTiB 4 10 – – – 20 CrMoVTiB 20 CrMoVTiB – – – – 1.7729 – 4-10 4-10 – PS 275 TMK S 275 ML – – S 275 ML S 275 ML S 275 ML – – – 1.8819 – – S 500 M – – – S 500 m – – – – – 1.8829 – – BTStE 460 TM S 460 ML – – S 460 ML E 460 S 460 ML – – – 1.8838 – – S 500 ML – – – S 500 ML – – – – – 1.8839 – – S 275 MH – – – S 275 MH – S 275 MH – – – 1.8843 – – S 275 MLH – – – S 275 MLH – S 275 MLH – – – 1.8844 – – S 355 MH – – – S 355 MH – S 355 MH – – – 1.8845 – – S 355 MLH – – – S 355 MLH – S 355 MLH – – – 1.8846 – – S 420 MH – – – S 420 MH – S 420 MH – – – 1.8847 – – S 420 MLH – – – S 420 MLH – S 420 MLH – – – 1.8848 – – S 460 MH – – – S 460 MH – S 460 MH – – – 1.8849 – – StE 460 S 460 N – – S 460 N E 460 S 460N – – – 1.8901 – – TStE 460 S 460 L – – S 460 NL E460 S 460 NL – – – 1.8903 – – S 550 Q – – – S 550 Q E 550 S 550 Q – – – 1.8904 – – S 460 Q 55 F – – S 460 Q E 460 S 460 Q – – – 1.8908 – – S 420 NL/TStE 420 S 420 NL STK 540 K02002 S 420 NL E 420 T–I Fe E 420 KT – – – 1.8912 – – S 620 Q – – – S 620 Q E 620 S 620 Q – – – 1.8914 – – T St E 460/P460NL1 P 460 NL 1 – K02900 P 460 NL1 E 460 T–I Fe E 460 KT – – – 1.8915 – – S 460 QL1 55 F – – S 460 QL 1 – – – – – 1.8916 – – T St E 500 – – K02001 – E 500 T–I – – – – 1.8917 – – EStE 460/P460Nl2 P 460 NL 2 – – P 460 NL 2 P 460 NL 2 P 460 NL 2 – – – 1.8918 – – EStE 500/S500NL1 – – – S 500 NL 1 – – – – – 1.8919 – – TStE 690 VA/S690G1QL – – – S 690 G 1 QL – – – – – 1.8920 – – TStE 690 VB/S690G2QL – – K11646 S 690 G 2 QL – – – – – 1.8921 – – S 690 G 4 QL/TStE 690 VC – – – S 690 G 4 QL – – – – – 1.8922 – – S 590 QL/TStE 590 V – – – S 590 QL – – – – – 1.8923 – – S 500 Q (StE 500 V) – – – S 500 Q E 500 S 500 Q 2614 – – 1.8924 – – S 890 QL 1 (EStE 90 V) – – – S 890 QL 1 – – – – – 1.8925 – – S 690 QL (TStE 690 V) – SHY 685 NS – S 690 QL – – – – – 1.8928 – – S 690 Q/StE 690 V – SHY 685 N – S 690 Q E 690 S 690 Q – – – 1.8931 – – WSt E 420/P420NH S 420 NL STK 540 K02002 S 420 NL S 420 NL Fe E 420 KW – – – 1.8932 – – S 960 QL/TStE 960 V – – – S 960 QL – – – – – 1.8933 – – WSt E 460/P460NH P 460 NH – K02900 P 460 NH P 460 NH Fe E 460 KW – – – 1.8935 – – S 960 Q – – – S 960 Q E 960 T–II S 960 Q – – – 1.8941 – – S 355 J 0 WP WR 50 A – – S 355 J0 WP E 36 W–A3 S 355 J0 WP – – – 1.8945 – – S 355 J 2 WP S 355 J 2 WP – – S 355 J2 WP E36W–A4 S 355 J2 WP – – – 1.8946 – – L 415 QB – – – L 415 QB L 415 QB – – – – 1.8947 – – L 360 QB – – – L 360 QB L 360 QB – – – – 1.8948 – – L 450 QB – – – L 450 QB L 450 QB – – – – 1.8952 – – S 460 NH (FGS 47) – – – S 460 NH – S 460 NH – – – 1.8953 – – L 485 QB – – – L 485 QB L 485 QB – – – – 1.8955 – – S 460 NLH/FG S 47 – – – S 460 NLH – S460NLH – – – 1.8956 – – L 555 QB – – – L 555 QB L 555 QB – – – – 1.8957 – – 9 CrNiCuP 3 2 4 WR 50 A SPA–H K11430 – – – – – – 1.8962 – – WTSt 52-3 WR 50 C SMA 58 W K11430 S 355 J 2 G 1 W E 36 W-A2 – – – – 1.8963 – – S 355 J 2 G 2 W S 355 J 2 G 2 W – – S 355 J 2 G 2 W S 355 J 2 G 2 W S 355 J 2 G 2 W – – – 1.8965 – (продолжение) Y196 kennametal.com

Каталог Kennametal инновации 2019.1

Каталог Kennametal инновации 2019.1 Каталог Kennametal инновации 2020.2

Каталог Kennametal инновации 2020.2 Каталог Kennametal инновации 2022.1

Каталог Kennametal инновации 2022.1 Основной каталог Kennametal вращающиеся инструменты 2018

Основной каталог Kennametal вращающиеся инструменты 2018 Каталог Kennametal инновации 2020.1

Каталог Kennametal инновации 2020.1 Каталог Kennametal инновации 2019.2

Каталог Kennametal инновации 2019.2