Техническая информация Sumitomo - страница 22

Навигация

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

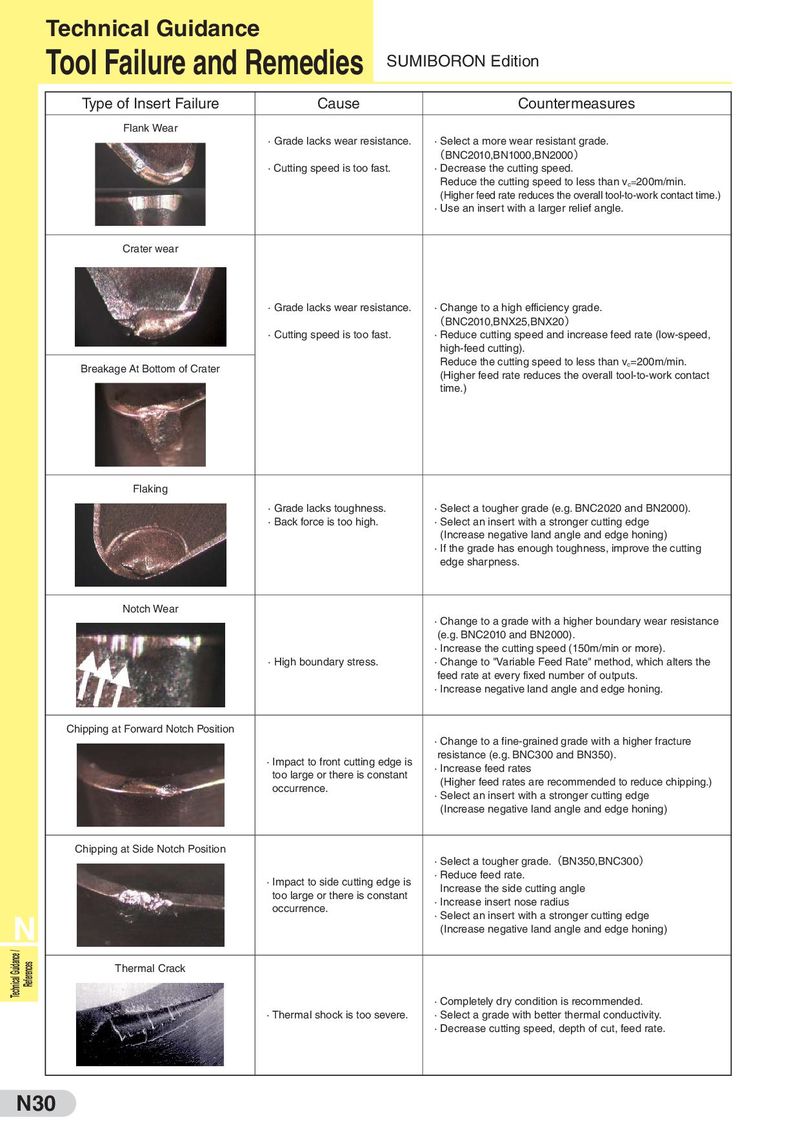

Technical Guidance Tool Failure and Remedies SUMIBORON Edition Type of Insert Failure Cause Countermeasures Flank Wear · Grade lacks wear resistance. · Select a more wear resistant grade. (BNC2010,BN1000,BN2000) · Cutting speed is too fast. · Decrease the cutting speed. Reduce the cutting speed to less than vc=200m/min. (Higher feed rate reduces the overall tool-to-work contact time.) · Use an insert with a larger relief angle. Crater wear · Grade lacks wear resistance. · Change to a high efficiency grade. (BNC2010,BNX25,BNX20) · Cutting speed is too fast. · Reduce cutting speed and increase feed rate (low-speed, high-feed cutting). Breakage At Bottom of Crater Reduce the cutting speed to less than vc=200m/min. (Higher feed rate reduces the overall tool-to-work contact time.) Flaking · Grade lacks toughness. · Select a tougher grade (e.g. BNC2020 and BN2000). · Back force is too high. · Select an insert with a stronger cutting edge (Increase negative land angle and edge honing) · If the grade has enough toughness, improve the cutting edge sharpness. Notch Wear · Change to a grade with a higher boundary wear resistance (e.g. BNC2010 and BN2000). · Increase the cutting speed (150m/min or more). · High boundary stress. · Change to "Variable Feed Rate" method, which alters the feed rate at every fixed number of outputs. · Increase negative land angle and edge honing. Chipping at Forward Notch Position · Change to a fine-grained grade with a higher fracture · Impact to front cutting edge is resistance (e.g. BNC300 and BN350). too large or there is constant · Increase feed rates occurrence. (Higher feed rates are recommended to reduce chipping.) · Select an insert with a stronger cutting edge (Increase negative land angle and edge honing) Chipping at Side Notch Position · Select a tougher grade.(BN350,BNC300) · Impact to side cutting edge is · Reduce feed rate. too large or there is constant Increase the side cutting angle occurrence. · Increase insert nose radius N · Select an insert with a stronger cutting edge (Increase negative land angle and edge honing) Technical Guidance / References Thermal Crack · Completely dry condition is recommended. · Thermal shock is too severe. · Select a grade with better thermal conductivity. · Decrease cutting speed, depth of cut, feed rate. N30