Техническая информация Sumitomo - страница 16

Навигация

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

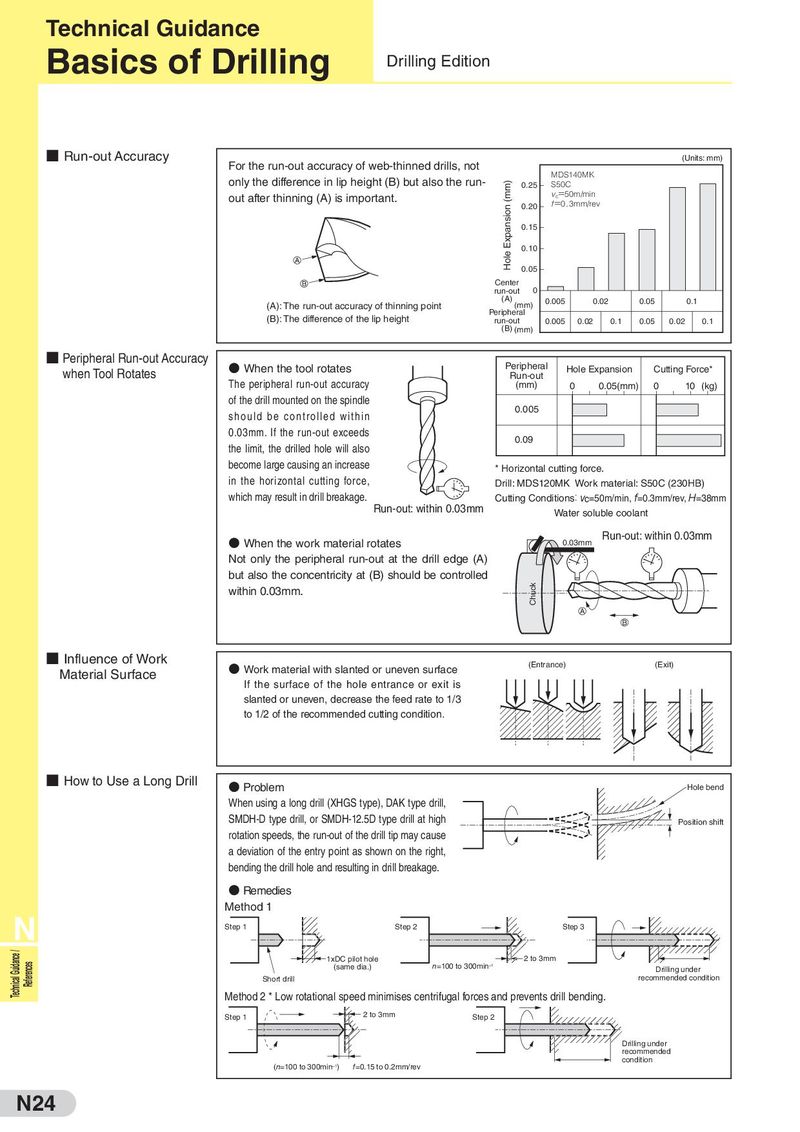

Technical Guidance Basics of Drilling Drilling Edition ■ Run-out Accuracy For the run-out accuracy of web-thinned drills, not (Units: mm) only the difference in lip height (B) but also the run- MDS140MK Hole Expansion (mm) 0.25 S50C out after thinning (A) is important. vc=50m/min 0.20 f=0.3mm/rev 0.15 0.10 0.05 Center run-out 0 (A): The run-out accuracy of thinning point (A) (mm) 0.005 0.02 0.05 0.1 (B): The difference of the lip height Peripheral run-out 0.005 0.02 0.1 0.05 0.02 0.1 (B) (mm) ■ Peripheral Run-out Accuracy ● When the tool rotates Peripheral when Tool Rotates Run-out Hole Expansion Cutting Force* The peripheral run-out accuracy (mm) 0 0.05(mm) 0 10 (kg) of the drill mounted on the spindle 0.005 should be controlled within 0.03mm. If the run-out exceeds 0.09 the limit, the drilled hole will also become large causing an increase * Horizontal cutting force. in the horizontal cutting force, Drill: MDS120MK Work material: S50C (230HB) which may result in drill breakage. Cutting Conditions: c=50m/min, =0.3mm/rev, =38mm Run-out: within 0.03mm Water soluble coolant ● When the work material rotates 0.03mm Run-out: within 0.03mm Not only the peripheral run-out at the drill edge (A) but also the concentricity at (B) should be controlled within 0.03mm. Chuck ■ Influence of Work ● Work material with slanted or uneven surface (Entrance) (Exit) Material Surface If the surface of the hole entrance or exit is slanted or uneven, decrease the feed rate to 1/3 to 1/2 of the recommended cutting condition. ■ How to Use a Long Drill ● Problem Hole bend When using a long drill (XHGS type), DAK type drill, SMDH-D type drill, or SMDH-12.5D type drill at high Position shift rotation speeds, the run-out of the drill tip may cause a deviation of the entry point as shown on the right, bending the drill hole and resulting in drill breakage. ● Remedies Method 1 N Step 1 Step 2 Step 3 Technical Guidance / References 1xDC pilot hole 2 to 3mm (same dia.) n=100 to 300min–1 Drilling under Short drill recommended condition Method 2 * Low rotational speed minimises centrifugal forces and prevents drill bending. Step 1 2 to 3mm Step 2 Drilling under recommended condition (n=100 to 300min–1) f=0.15 to 0.2mm/rev N24