Общий каталог Yamawa 2021 - страница 191

Навигация

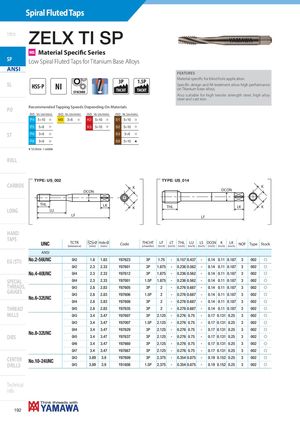

Spiral Fluted Taps Intro ZELX TI SP MS Material Specific Series SP Low Spiral Fluted Taps for Titanium Base Alloys ANSI FEATURES SL HSS-P NI SYNCHRO 3P 1.5PTHCHTTHCHT Material specific for blind hole application.Specific design and NI treatment allow high performanceon Titanium base alloys. Also suitable for high tensile strength steel, high alloy steel and cast iron. PO Recommended Tapping Speeds Depending On Materials ISO Vc (m/min) ISO Vc (m/min) ISO Vc (m/min) ISO Vc (m/min) P4 5÷10 I M3 3÷6 I K2 5÷10 I S1 5÷10 I P5 5÷8 I K3 5÷10 I S2 5÷10 I ST P6 3÷6 I S3 3÷6 I P8 3÷6 I S5 5÷10 H H 1st choice I suitable ROLL ANSI-ZELX TI SP TYPE: US_002 TYPE: US_014 CARBIDE KDCON KDCON THLLONGLU LK K THL LK K LF LF HAND TAPS UNC TCTR Ø Hole Ø(tolerance)(mm)(mm)CodeTHCHT(chamfer)LF LT THL LU LS DCON K LK(inch)(inch)(inch)(inch)(inch)(inch)(inch)(inch)NOFType Stock ANSI EG (STI) No.2-56UNC GH2 1.8 1.83 Y87623 3P 1.75 - 0.157 0.437 - 0.14 0.11 0.187 3 002 f GH2 2.3 2.33 Y87601 3P 1.875 - 0.236 0.562 - 0.14 0.11 0.187 3 002 f No.4-40UNC GH4 2.3 2.33 Y87612 3P 1.875 - 0.236 0.562 - 0.14 0.11 0.187 3 002 f SPECIAL GH4 2.3 2.33 Y87001 1.5P 1.875 - 0.236 0.562 - 0.14 0.11 0.187 3 002 f THREADS, GH3 2.8 2.83 Y87605 3P 2 - 0.276 0.687 - 0.14 0.11 0.187 3 002 f GAUGES GH3 2.8 2.83 Y87606 1.5P 2 - 0.276 0.687 - 0.14 0.11 0.187 3 002 f No.6-32UNC GH4 2.8 2.83 Y87608 3P 2 - 0.276 0.687 - 0.14 0.11 0.187 3 002 f THREAD GH5 2.8 2.83 Y87635 3P 2 - 0.276 0.687 - 0.14 0.11 0.187 3 002 f MILLS GH3 3.4 3.47 Y87607 3P 2.125 - 0.276 0.75 - 0.17 0.131 0.25 3 002 f GH3 3.4 3.47 Y87007 1.5P 2.125 - 0.276 0.75 - 0.17 0.131 0.25 3 002 f GH4 3.4 3.47 Y87629 3P 2.125 - 0.276 0.75 - 0.17 0.131 0.25 3 002 f No.8-32UNC DIES GH5 3.4 3.47 Y87637 3P 2.125 - 0.276 0.75 - 0.17 0.131 0.25 3 002 f GH6 3.4 3.47 Y87660 3P 2.125 - 0.276 0.75 - 0.17 0.131 0.25 3 002 f GH7 3.4 3.47 Y87667 3P 2.125 - 0.276 0.75 - 0.17 0.131 0.25 3 002 f CENTER No.10-24UNC GH3 3.89 3.9 Y87609 3P 2.375 - 0.354 0.875 - 0.19 0.152 0.25 3 002 f DRILLS GH3 3.89 3.9 Y81608 1.5P 2.375 - 0.354 0.875 - 0.19 0.152 0.25 3 002 f Technical info 192

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали