Основной каталог Winstar 2021 - страница 389

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

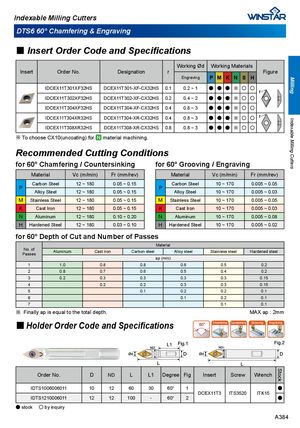

Stock Indexable Milling CuttersMilling Indexable Milling Cutters DTS6 60° Chamfering & Engraving ■ Insert Order Code and Specifications Working Ød Working Materials Insert Order No. Designation r Figure Engraving P M K N S H IDCEX11T301XF32HS DCEX11T301-XF-CX32HS 0.1 0.2 ~ 1 ● ● ● ※ ○ ○ IDCEX11T302XF32HS DCEX11T302-XF-CX32HS 0.2 0.4 ~ 2 ● ● ● ※ ○ ○ IDCEX11T304XF32HS DCEX11T304-XF-CX32HS 0.4 0.8 ~ 3 ● ● ● ※ ○ ○ IDCEX11T304XR32HS DCEX11T304-XR-CX32HS 0.4 0.8 ~ 3 ● ● ● ※ ○ ○ IDCEX11T308XR32HS DCEX11T308-XR-CX32HS 0.8 0.8 ~ 3 ● ● ● ※ ○ ○ ※ To choose CX10(uncoating) for material machining. Recommended Cutting Conditions for 60° Chamfering / Countersinking for 60° Grooving / Engraving Material Vc (m/min) Fr (mm/rev) Material Vc (m/min) Fr (mm/rev) Carbon Steel 12 ~ 180 0.05 ~ 0.15 Carbon Steel 10 ~ 170 0.005 ~ 0.05 P P Alloy Steel 12 ~ 180 0.05 ~ 0.15 Alloy Steel 10 ~ 170 0.005 ~ 0.03 M Stainless Steel 12 ~ 180 0.05 ~ 0.15 M Stainless Steel 10 ~ 170 0.005 ~ 0.05 K Cast Iron 12 ~ 180 0.05 ~ 0.15 K Cast Iron 10 ~ 170 0.005 ~ 0.03 N Aluminum 12 ~ 180 0.10 ~ 0.20 N Aluminum 10 ~ 170 0.005 ~ 0.08 H Hardened Steel 12 ~ 180 0.03 ~ 0.10 H Hardened Steel 10 ~ 170 0.005 ~ 0.02 for 60° Depth of Cut and Number of Passes Material No. ofPasses Aluminum Cast iron Carbon steel Alloy steel Stainless steel Hardened steel ap (mm) 1 1.0 0.8 0.8 0.6 0.5 0.2 2 0.8 0.7 0.6 0.5 0.4 0.2 3 0.2 0.3 0.3 0.3 0.3 0.15 4 0.2 0.2 0.3 0.3 0.15 5 0.1 0.2 0.2 0.1 6 0.1 0.2 0.1 7 0.1 0.1 ※ Finally ap is equal to the total depth. MAX ap : 2mm ■ Holder Order Code and Specifications Order No. D ND L L1 Degree Fig Insert Screw Wrench IDTS1006006011 10 12 60 30 60° 1 ● DCEX11T3 ITS3520 ITK15 IDTS1210006011 12 12 100 - 60° 2 ● ● stock ○ by inquiry A384

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020