Основной каталог Winstar 2021 - страница 213

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

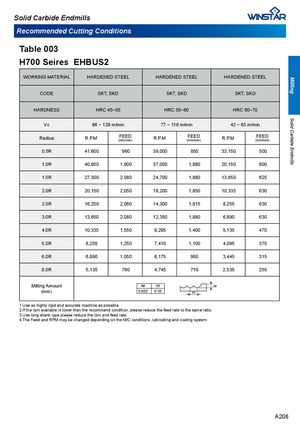

Solid Carbide EndmillsMilling Solid Carbide Endmills Recommended Cutting Conditions Table 003 H700 Seires EHBUS2 WORKING MATERIAL HARDENED STEEL HARDENED STEEL HARDENED STEEL CODE SKT, SKD SKT, SKD SKT, SKD HARDNESS HRC 45~55 HRC 55~60 HRC 60~70 Vc 86 ~ 129 m/min 77 ~ 116 m/min 42 ~ 63 m/min Radius R.P.M FEED (mm/min) R.P.M FEED (mm/min) R.P.M FEED (mm/min) 0.5R 41,600 960 39,000 850 33,150 500 1.0R 40,950 1,900 37,050 1,880 20,150 600 1.5R 27,300 2,080 24,700 1,880 13,650 625 2.0R 20,150 2,050 18,200 1,850 10,335 630 2.5R 16,250 2,060 14,300 1,815 8,255 630 3.0R 13,650 2,080 12,350 1,880 6,890 630 4.0R 10,335 1,550 9,295 1,400 5,135 470 5.0R 8,255 1,250 7,410 1,100 4,095 375 6.0R 6,890 1,050 6,175 950 3,445 315 8.0R 5,135 790 4,745 710 2,535 230 Milling Amount (mm) 1.Use as highly rigid and accurate machine as possible. 2.If the rpm available is lower than the recommend condition, please reduce the feed rate to the same ratio. 3.Use long shank type please reduce the rpm and feed rate. 4.The Feed and RPM may be changed depending on the M/C conditions ,lubricating and cooling system. A208

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020