Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 309

Навигация

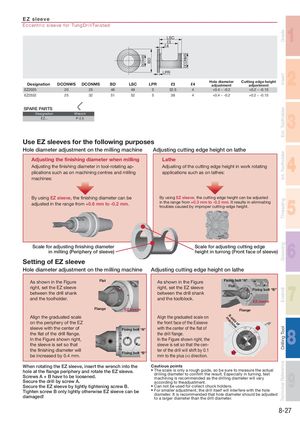

DCONWS BD DCONMS GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference EZ sleeve Eccentric sleeve for Tu n g D r i l l Tw i s t e d LSCℓ3 1 ℓ4 LPRDesignationDCONWSDCONMSBDLSCLPRℓ3ℓ4Hole diameter Cutting edge height 2adjustmentadjustment EZ2025 20 25 46 49 5 32.5 4 +0.4 ~ -0.2 +0.2 ~ -0.15 EZ2532 25 32 51 52 5 38 4 +0.4 ~ -0.2 +0.2 ~ -0.15 SPARE PARTS Designation WrenchEZ...P-2.5 3 Use EZ sleeves for the following purposes Hole diameter adjustment on the milling machine Adjusting cutting edge height on lathe Adjusting the finishing diameter when millingAdjusting the finishing diameter in tool-rotating ap-LatheAdjusting of the cutting edge height in work rotating 4 plications such as on machining centres and milling applications such as on lathes: machines: By using EZ sleeve, the finishing diameter can beadjusted in the range from +0.6 mm to -0.2 mm.By using EZ sleeve, the cutting edge height can be adjustedin the range from +0.3 mm to -0.2 mm. It results in eliminatingtroubles caused by improper cutting-edge height.5 Scale for adjusting finishing diameterin milling (Periphery of sleeve) Scale for adjusting cutting edgeheight in turning (Front face of sleeve) 6 Setting of EZ sleeve Hole diameter adjustment on the milling machine Adjusting cutting edge height on lathe As shown in the Figure Flat As shown in the Figure Fixing bolt “A” right, set the EZ sleevebetween the drill shankand the toolholder. right, set the EZ sleevebetween the drill shankand the toolblock.FlatFixing bolt “B” 7 EZ sleeve Flange EZ sleeve Flange Align the graduated scale Align the graduated scale on on the periphery of the EZ the front face of the Esleeve sleeve with the center of Fixing bolt “A” with the center of the flat ofthe flat of the drill flange.the drill flange.In the Figure shown right,In the Figure shown right, the(+)8 the sleeve is set so that sleeve is set so that the cen- the finishing diameter willbe increased by 0.4 mm. ter of the drill will shift by 0.1Fixing bolt “B”mm to the plus (+) direction.(-) When rotating the EZ sleeve, insert the wrench into the Cautious points hole at the flange periphery and rotate the EZ sleeve.Screws A + B have to be loosened.Secure the drill by screw A.Secure the EZ sleeve by lightly tightening screw B.• The scale is only a rough guide, so be sure to measure the actualdrilling diameter to confirm the result. Especially in turning, testmachining is recommended as the drilling diameter will varyaccording to theadjustment.• Can not be used for collect chuck holders.9 Tighten screw B only lightly otherwise EZ sleeve can bedamaged! • For smaller adjustment, the drill itself will interfere with the holediameter. It is recommended that hole diameter should be adjustedto a larger diameter than the drill diameter. 8-27 +0.2+0.4 X-maxaischoifne

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1