Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 268

Навигация

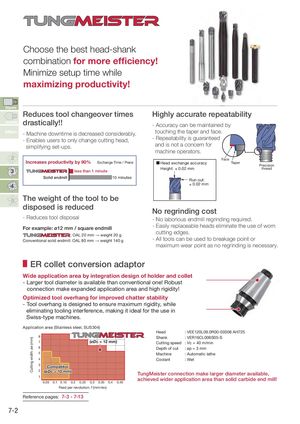

Choose the best head-shank combination for more efficiency! Minimize setup time while maximizing productivity! Square Reduces tool changeover times Highly accurate repeatability chamfering drastically!! - Accuracy can be maintained by Others - Machine downtime is decreased considerably. touching the taper and face. - Enables users to only change cutting head, - Repeatability is guaranteed simplifying set-ups. and is not a concern for machine operators. Increases productivity by 90% Exchange Time / Piece FaceHead exchange accuracyTaperPrecision 3 less than 1 minute Height: ± 0.02 mm thread Solid endmill 10 minutes Run out: 4 ≤ 0.02 mm The weight of the tool to be disposed is reduced No regrinding cost - Reduces tool disposal - No laborious endmill regrinding required. For example: ø12 mm / square endmill - Easily replaceable heads eliminate the use of worn : OAL 20 mm → weight 20 g cutting edges. Conventional solid endmill: OAL 80 mm → weight 140 g - All tools can be used to breakage point or maximum wear point as no regrinding is necessary. ER collet conversion adaptor Wide application area by integration design of holder and collet - Larger tool diameter is available than conventional one! Robust connection make expanded application area and high rigidity! Optimized tool overhang for improved chatter stability - Tool overhang is designed to ensure maximum rigidity, while eliminating tooling interference, making it ideal for the use in Swiss-type machines. Application area (Stainless steel, SUS304) Head : VEE120L09.0R00-03S08 AH725 8 Shank : VER16CL006S05-S 7 (øDc = 12 mm) Cutting speed : Vc = 40 m/min 6 Depth of cut : ap = 3 mm 5 Machine : Automatic lathe 4 Coolant : Wet 3 Competitor 2 (øDc = 10 mm) TungMeister connection make larger diameter available, 1 achieved wider application area than solid carbide end mill! 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 Feed per revolution: f (mm/rev) Reference pages: 7-3 - 7-13 7-2 Cutting width: ae (mm)

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1