Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 297

Навигация

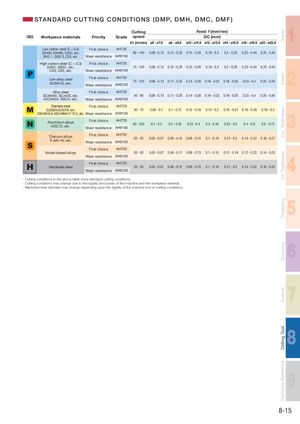

GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference S TA N D A R D CUTTING CONDITIONS ( D M P, DMH, DMC, DMF) Cutting Feed: f (mm/rev)ISOWorkpiece materialsPriorityGradespeedDC (mm) 1 Vc (m/min) ø6 - ø7.9 ø8 - ø9.9 ø10 - ø11.9 ø12 - ø13.9 ø14 - ø15.9 ø16 - ø19.9 ø20 - ø22.9 Low carbon steel (C < 0.3) First choice AH725 SS400, SM490, S25C, etc. 80 - 140 0.09 - 0.13 0.12 - 0.25 0.15 - 0.28 0.18 - 0.3 0.2 - 0.35 0.25 - 0.45 0.25 - 0.45 St42-1, St52-3, C25, etc. Wear resistance AH9130 High carbon steel (C > 0.3) First choice AH725 S45C, S55C, etc. 70 - 120 0.09 - 0.13 0.12 - 0.25 0.15 - 0.28 0.18 - 0.3 0.2 - 0.35 0.25 - 0.45 0.25 - 0.45 C45, C55, etc.Low alloy steelSCM415, etc.Wear resistanceAH9130First choiceAH72570 - 1200.08 - 0.130.11 - 0.250.14 - 0.280.16 - 0.320.18 - 0.350.23 - 0.40.25 - 0.45Wear resistanceAH9130 2 Alloy steel First choice AH725 SCM440, SCr420, etc. 40 - 90 0.08 - 0.13 0.11 - 0.25 0.14 - 0.28 0.16 - 0.32 0.18 - 0.35 0.23 - 0.4 0.25 - 0.45 42CrMo4, 20Cr4, etc. Wear resistance AH9130 Stainless steel First choice AH725 SUS304,SUS316, etc. 30 - 70 0.08 - 0.1 0.1 - 0.15 0.12 - 0.18 0.14 - 0.2 0.16 - 0.24 0.16 - 0.26 0.18 - 0.3 X5CrNi18-9, X5CrNiMo17-12-2, etc. Wear resistance AH9130Aluminium alloysADC12, etc.First choiceAH72580 - 2200.1 - 0.20.2 - 0.350.25 - 0.40.3 - 0.450.35 - 0.50.4 - 0.60.5 - 0.75Wear resistanceAH91303 Titanium alloysTi-6Al-4V, etc.First choice AH725 20 - 50 0.05 - 0.07 0.06 - 0.12 0.08 - 0.15 0.1 - 0.18 0.12 - 0.2 0.14 - 0.22 0.18 - 0.27Wear resistanceAH9130 First choice AH725 Nickel-based alloys 20 - 50 0.05 - 0.07 0.06 - 0.11 0.08 - 0.13 0.1 - 0.15 0.12 - 0.18 0.12 - 0.22 0.14 - 0.25 Hardened steel Wear resistance AH9130First choiceAH72520 - 500.05 - 0.070.06 - 0.12 0.08 - 0.15 0.1 - 0.18 0.12 - 0.2 0.14 - 0.22 0.16 - 0.25Wear resistanceAH9130 4 - Cutting conditions in the above table show standard cutting conditions. - Cutting conditions may change due to the rigidity and power of the machine and the workpiece material. - Machined hole diameter may change depending upon the rigidity of the machine tool or cutting conditions. 5 6 7 8 9 8-15

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1