Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 263

Навигация

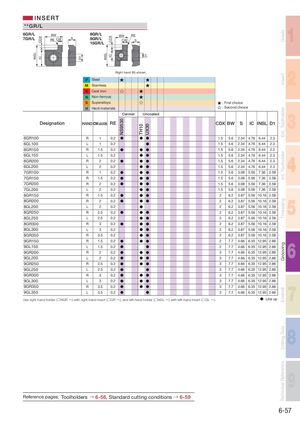

INSL CDXIC D1 INSL CDXIC NS9530 TH10 D1UX30 GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference INSERT **GR/L6GR/L BW 8GR/L BW RE7GR/LRECWS9GR/LCWS 1 15GR/L Right hand (R) shown.PSteel 2 M Stainless K Cast iron N Non-ferrous S Superalloys : First choice H Hard materials : Second choice Cermet UncoatedDesignationHAND CW±0.025RE CDX BW S IC INSL D1 3 6GR100 R 1 0.2 1.5 5.6 2.34 4.76 6.44 2.3 6GL100 L 1 0.2 1.5 5.6 2.34 4.76 6.44 2.3 6GR150 R 1.5 0.2 1.5 5.6 2.34 4.76 6.44 2.3 6GL150 L 1.5 0.26GR200R20.26GL200L20.2 1.5 5.6 2.34 4.76 6.44 2.31.55.62.344.766.442.31.55.62.344.766.442.34 7GR100 R 1 0.2 1.5 5.6 3.08 5.56 7.36 2.58 7GR150 R 1.5 0.2 1.5 5.6 3.08 5.56 7.36 2.58 7GR200 R 2 0.2 1.5 5.6 3.08 5.56 7.36 2.58 7GL200 L 2 0.2 1.5 5.6 3.08 5.56 7.36 2.58 8GR150 R 1.5 0.2 2 6.2 3.87 5.56 10.16 2.58 8GR200 R 2 0.28GL200L20.28GR250R2.50.2 2 6.2 3.87 5.56 10.16 2.5826.23.875.5610.162.5826.23.875.5610.162.585 8GL250 L 2.5 0.2 2 6.2 3.87 5.56 10.16 2.58 8GR300 R 3 0.2 2 6.2 3.87 5.56 10.16 2.58 8GL300 L 3 0.2 2 6.2 3.87 5.56 10.16 2.58 8GR350 R 3.5 0.2 2 6.2 3.87 5.56 10.16 2.58 9GR150 R 1.5 0.2 2 7.7 4.66 6.35 12.95 2.86 9GL150 L 1.5 0.29GR200R20.2 2 7.7 4.66 6.35 12.95 2.8637.74.666.3512.952.86 6 9GL200 L 2 0.2 3 7.7 4.66 6.35 12.95 2.86 9GR250 R 2.5 0.2 3 7.7 4.66 6.35 12.95 2.86 9GL250 L 2.5 0.2 3 7.7 4.66 6.35 12.95 2.86 9GR300 R 3 0.2 3 7.7 4.66 6.35 12.95 2.86 9GL300 L 3 0.2 3 7.7 4.66 6.35 12.95 2.86 9GR350 R 3.5 0.2 3 7.7 4.66 6.35 12.95 2.869GL350L3.50.237.74.666.3512.952.86Use right-hand holder (□NGR 〜) with right-hand insert (□GR 〜); and left-hand holder (□NGL 〜) with left-hand insert (□GL 〜).: Line up7 8 9 Reference pages: Toolholders → 6-56, Standard cutting conditions → 6-59 6-57

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1