Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 2

Навигация

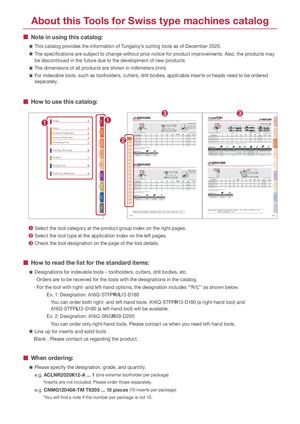

GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference WFHF WFHF BH BH HBKW HBKW WF OAWHF OAW BHWFHF WF OAWHF BH WFBH OAWHF BH GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference About this Tools for Swiss type machines catalog ■ Note in using this catalog: ★ This catalog provides the information of Tungaloy’s cutting tools as of December 2020. ★ The specifications are subject to change without prior notice for product improvements. Also, the products may be discontinued in the future due to the development of new products. ★ The dimensions of all products are shown in millimeters (mm). ★ For indexable tools, such as toolholders, cutters, drill bodies, applicable inserts or heads need to be ordered separately. ■ How to use this catalog: ❸ ❸ ❶ Grade 1 1❶ JSDJ2CR/LScrew-on toolholder with 93° approach angle, for positive 55° rhombic inserts JSDJ2CR/L-CHPScrew-on toolholder with 93° approach angle, for positive 55° rhombic inserts, with high pressure coolant capability 1Without offsetWithout offset JSDJ2CR/L1010X11 30° LFLH LFLH LFLH Insert 2 LH JSDJ2CR/L1212F11LFJSDJ2CR/L1212X1130° 93° 5/16”-24UNF 5/16”-24UNF 93° External To o l h o l d e r 3 2 Cutting edge style J2 Right hand (R) shown. Cutting edge style J2 Fig.1 5/16”-24UNFFig.2 Fig.3 Right hand (R) shown. 2 Designation H B LF LH HF WF HBKW RE** Insert Torque* Designation H B LF LH HF WF OAW RE** Insert Torque* Fig. JSDJ2CR/L0808F07 8 8 85 14 8 8 - 0.2 DC**0702... 1.2 JSDJ2CR1012H07-CHP (*) 10 12 100 17 10 0 16.4 0.2 DC**0702... 1.2 1 Internal To o l h o l d e r 4ThreadingTo o l5 3 JSDJ2CR/L1010X07 10 10 120 14 10 10 - 0.2 DC**0702... 1.2 JSDJ2CR/L1212F07-CHP 12 12 85 18 12 0 18 0.2 DC**0702... 1.2 3❷DC**JSDJ2CR/L1010X11JSDJ2CR/L1212F07DXGUJSDJ2CR/L1212F1110121210120201285141285201012121012124-20.2DC**11T3...1.20.2DC**0702...1.20.2DC**11T3...1.2JSDJ2CR/L1212X071212120141212-0.2DC**0702...1.2JSDJ2CR/L1212X11121212020121220.2DC**11T3...1.2JSDJ2CR/L1212F11-CHP1212851912020.50.2DC**11T3...1.23JSDJ2CR1212X11-CHP (*)12121201912020.50.2DC**11T3...1.22JSDJ2CR1616X11-CHP (*)16161201916020.50.2DC**11T3...1.22(*) Direct coolant supply*Torque: Recommended clamping torque (N∙m)**RE: Standard corner radius3 CC** JSDJ2CR/L1616X11 16 16 120 20 16 16 - 0.2 DC**11T3... 1.2 SPARE PARTS *Torque: Recommended clamping torque (N∙m) Parting, Grooving 6 WXGU **RE: Standard corner radius Designation ClampingscrewCoolant nozzle Nozzle retainerscrewCoolant unit Wrench 1 Coolant plug Wrench DirectJet plug Wrench 2JSDJ2CR1012H07-CHPCSTB-2.5NZ-1.10-7-CHPSSHM4-4-TB-T-8FSR5/16UNFTL360P-4SSHM4-6-TBP-2 4 SPARE PARTSVB** Designation Clamping screw WrenchJSDJ2CR/L**07CSTB-2.5T-8FJSDJ2CR/L**11CSTB-4SDT-8F JSDJ2CR/L1212F07-CHP CSTB-2.5 - - S-CU-CHP T-8F SR5/16UNFTL360 P-4 - -JSDJ2CR/L1212F11-CHPCSTB-4SD--S-CU-CHPT-8FSR5/16UNFTL360P-4--JSDJ2CR**11-CHPCSTB-4SD-S-CU-CHP-T-8FSR5/16UNFTL360P-4SSHM4-6-TBP-24 Endmill 7 VXGU VP** Drilling Tool 8 5 VC**TC**JTDJ2CR/LBack-clamp toolholder with 93° approach angle, for positive 55° rhombic inserts JSDJCR-FScrew-onstepped-head toolholder with 93° approach angle, for positive 55° rhombic inserts 5LF YWMT Without offset HBKL JTDJ2CR/L1212F11 93° Technical Reference 9 6 JTDJ2CR/L1212X11TN**LHLF30°93° L2LH 6 CN** Cutting edge style J Right hand (R) shown. Cutting edge style J2 Right hand (R) shown. Designation H B LF L2 HBKL LH HF WF OAW RE** Insert Torque* WN** Designation H B LF LH HF WF HBKW RE** Insert Torque* JSDJCR1016X07-F15 10 16 120 12.5 27 14 10 15 26 0.2 DC**0702... 1.2 JTDJ2CR/L1010X07 10 10 120 14 10 10 - 0.2 DC**0702... 0.9 JSDJCR1216F07-F15 12 16 85 12.5 27 14 12 15 26 0.2 DC**0702... 1.2 7 JTDJ2CR/L1212F07 12 12 85 14 12 12 - 0.2 DC**0702... 0.9DN**JTDJ2CR/L1212X071212120141212-0.2DC**0702...0.9JTDJ2CR/L1212F1112128520121220.2DC**11T3...1.2JSDJCR1216X07-F151216 120 12.5 27 14 12 15 26 0.2 DC**0702... 1.2JSDJCR1216F11-F15JSDJCR1216X11-F15JSDJCR1620X11-F1512168512.527201215280.2DC**11T3...1.2121612012.527201215280.2DC**11T3...1.2162012012.527201615280.2DC**11T3...1.27 VN** JTDJ2CR/L1212X11 12 12 120 20 12 12 2 0.2 DC**11T3... 1.2 JTDJ2CR/L1616X11 16 16 120 20 16 16 - 0.2 DC**11T3... 1.2 *Torque: Recommended clamping torque (N∙m) **RE: Standard corner radius JXF *Torque: Recommended clamping torque (N∙m)**RE: Standard corner radius SPARE PARTS 8 JXB SPARE PARTS Designation Clamp Clamping screw WrenchJTDJ2CR/L**07JCP-2JDS-3525P-2F Designation Clamping screw WrenchJSDJCR**07-F15CSTB-2.5 T-8FJSDJCR**11-F15CSTB-4SDT-8F 8 J10E JTDJ2CR/L**11 JCP-3 JDS-5040 P-2.5F JTB 9 9 Reference pages : JSDJ2CR/L-CHP, JSDJCR-F: Inserts → 2-15 -, CBN → 2-63, PCD → 2-70 Reference pages : JSDJ2CR/L, JTDJ2CR/L: Inserts → 2-15 -, CBN →2-63, PCD → 2-70 Parts for coolant hose → 3-61 3-12 3-13 ❶ Select the tool category at the product group index on the right pages. ❷ Select the tool type at the application index on the left pages. ❸ Check the tool designation on the page of the tool details. ■ How to read the list for the standard items: ★ Designations for indexable tools – toolholders, cutters, drill bodies, etc. · Orders are to be received for the tools with the designations in the catalog. · For the tool with right- and left-hand options, the designation includes **R/L** as shown below. Ex. 1: Designation: A16Q-STFPR/L13-D180 You can order both right- and left-hand tools. A16Q-STFPR13-D180 (a right-hand tool) and A16Q-STFPL13-D180 (a left-hand tool) will be available. Ex. 2: Designation: A16Q-SNGR09-D200 You can order only right-hand tools. Please contact us when you need left-hand tools. ★ Line up for inserts and solid tools Blank : Please contact us regarding the product. ■ When ordering: ★ Please specify the designation, grade, and quantity. e.g. ACLNR2020K12-A ... 1 (one external toolholder per package) *Inserts are not included. Please order those separately. e.g. CNMG120408-TM T9205 ... 10 pieces (10 inserts per package) *You will find a note if the number per package is not 10.

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1