Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 149

Навигация

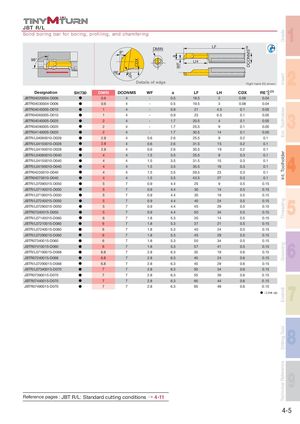

CDX a WF DCONMSh6 GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference 20º INI JBT R/LSolidboringbarfor boring, profiling, and chamfering 1 DMIN LF 8º 98° LH RE Details of edge Right hand (R) shown. 2 Designation SH730 DMIN DCONMS WF a LF LH CDX RE +0.05 0 JBTR04020004-D006 䖃 0.6 4 - 0.5 18.5 2 0.08 0.04 JBTR04030004-D006 䖃 0.6 4 - 0.5 19.5 3 0.08 0.04 JBTR04045005-D010 䖃 1 4 - 0.9 21 4.5 0.1 0.05 JBTR04065005-D010 䖃 1JBTR04040005-D020䖃2JBTR04090005-D020䖃2444---0.9 23 6.51.720.541.725.590.1 0.050.10.050.10.05 3 JBTR04140005-D020 䖃 2 4 - 1.7 30.5 14 0.1 0.05 JBTR/L04090010-D028 䖃 2.8 4 0.6 2.6 25.5 9 0.2 0.1 JBTR/L04150010-D028 䖃 2.8 4 0.6 2.6 31.5 15 0.2 0.1 JBTR/L04190010-D028 䖃 2.8 4 0.6 2.6 35.5 19 0.2 0.1 JBTR/L04090010-D040 䖃 4JBTR/L04150010-D040䖃4JBTR/L04190010-D040䖃44441.53.525.5 9 0.3 0.11.53.531.5150.30.11.53.535.5190.30.1 4 JBTR04230010-D040 䖃 4 4 1.5 3.5 39.5 23 0.3 0.1 JBTR04270010-D040 䖃 4 4 1.5 3.5 43.5 27 0.3 0.1 JBTR/L07090015-D050 䖃 5 7 0.9 4.4 25 9 0.5 0.15 JBTR/L07140015-D050 䖃 5 7 0.9 4.4 30 14 0.5 0.15 JBTR/L07190015-D050 䖃 5 7 0.9 4.4 35 19 0.5 0.15 JBTR/L07240015-D050 䖃 5JBTR/L07290015-D050䖃5JBTR07340015-D050䖃57770.94.4 400.94.4450.94.450242934 0.5 0.150.50.150.50.15 5 JBTR/L07140015-D060 䖃 6 7 1.8 5.3 30 14 0.5 0.15 JBTR/L07210015-D060 䖃 6 7 1.8 5.3 37 21 0.5 0.15 JBTR/L07240015-D060 䖃 6 7 1.8 5.3 40 24 0.5 0.15 JBTR/L07290015-D060 䖃 6 7 1.8 5.3 45 29 0.5 0.15 JBTR07340015-D060 䖃 6 7 1.8 5.3 50 34 0.5 0.15 JBTR07410015-D060 䖃JBTR/L07190015-D068䖃JBTR07240015-D068䖃66.86.87771.8 5.3 572.86.3352.86.340411924 0.50.6 0.150.15 60.60.15 JBTR/L07290015-D068 䖃 6.8 7 2.8 6.3 45 29 0.6 0.15 JBTR/L07340015-D070 䖃 7 7 2.8 6.3 50 34 0.6 0.15 JBTR07390015-D070 䖃 7 7 2.8 6.3 55 39 0.6 0.15 JBTR07440015-D070 䖃 7 7 2.8 6.3 60 44 0.6 0.15 JBTR07490015-D070 䖃 7 7 2.8 6.3 65 49 0.6 0.15䖃 : Line up 7 8 9 Reference pages : JBT R/L: Standard cutting conditions → 4-11 4-5

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1