Каталог TooTool техническая информация 2 - страница 192

Навигация

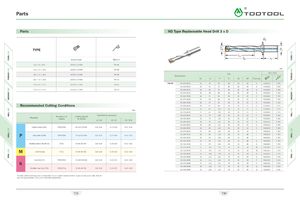

A\ Parts HD Type Replaceable Head Drill 3 x D d4 i J + TYPE Dc dl Insert screw Wrench t «* Lc 14 tI5 12.0 = D = 15.5 SSTX 2.2- 3.0PXD TPF-06 15.5 < D = 18.5 SSTX 2.5-3.6PXD TPF -08 mm 18.5 < D = 21.5 SSTX3.0-4.0PXD TPF-08 Size Spare PartsDesignation 21.5 < D = 24.8 SSTX 3.5- 5.5 PXD TPF-15 Dc Lc 14 15 dl d4 Seat size 24.8< D = 27.8 SSTX4.0- 5.7PXD TPF -15 HD-XD 03-120-XP16 12 36 68 48 16 20 A FS3011D T-10S 03-130-XP16 13 41 72 48 16 20 A FS3012D T-10S 27.8 < D = 33.5 SSTX4.5- 5.7PXD TPF-20 03-140-XP16 14 45 76 48 16 20 B FS3013D T-10S 03-150-XP16 15 48 80 48 16 20 B FS3013D T-10S 03-160-XP20 16 51 84 50 20 25 C FS3514D T-15S 03-170-XP20 17 54 88 50 20 25 C FS3514D T-15S 03-180-XP20 18 57 92 50 20 25 D FS3515D T-15S Recommended Cutting Conditions 03-190-XP20 19 61 96 50 20 25 D FS3516D T-15S 03-200-XP20 20 64 100 50 20 25 E FS4018D T-15S mm 03-210-XP20 21 67 104 50 20 25 E FS4018D T-15S Materials Recommend Cutting Speed Feed Rate fn (mm/rev)InsertsVc m/min- 121616-20-2030.8 03-220-XP25 22 70 109 56 25 32 F FS5019D T- 20S03-230-XP252373113562532FFS5019DT- 20S 03-240-XP25 24 76 117 56 25 32 G FS5021D T-20S 03-250-XP25 25 80 121 56 25 32 G FS5021D T-20S Carbon Steel (SxxC) TCPA/TCEA 80-110 (50-80) 0.15 -0.30 0.15-0.30 0.15 -0.35 03-260-XP25 26 83 125 56 25 32 H FS6023D T-25S 03-270-XP25 27 86 129 56 25 32 H FS6023D T-25S P Alloy Steel (SCM) TCPA/TCEA 70-110 (50-80) 0.15 -0.30 0.15-0.30 0.15 -0.35 03-280-XP32 28 89 134 60 32 40 J FS6025D T-25S 03-290-XP32 29 92 138 60 32 40 J FS6025D T- 25S 03 - 300- XP32 30 95 142 60 32 40 K FS6028D T-25S Hardnesssteel (HRC40-50) TCPA 40-80 (30-70) 0.10-0.20 0.10-0.20 0.15 -0.25 03 - 310- XP32 31 99 146 60 32 40 K FS6028D T- 25S 03 - 320- XP40 32 102 150 70 40 50 M FS6028D T- 25S M -200HB Gray TCEA 50-80 (40-60) 0.10-0.20 0.10-0.20 0.15 -0.25 03 - 330- XP40 33 105 154 70 40 50 M FS6030D T- 25S 03 - 340- XP40 34 108 158 70 40 50 N FS6030D T-25S 03 - 350- XP40 35 111 162 70 40 50 N FS6030D T-25S Cast Iron (FC) TCPA/TCEA 50-100 (40-80) 0.15-0.30 0.15-0.35 0.15 -0.40 03-360-XP40 36 115 166 70 40 50 P FS6033D T-25S K 03-370-XP40 37 118 170 70 40 50 P FS6033D T-25S 03 - 380- XP40 38 121 173 70 40 50 Q FS6035D T-25S Nodular Cast Iron (FCD) TCPA/TCEA 50-90 (40-70) 0.15 -0.30 0.15-0.35 0.15 -0.35 03 - 390- XP40 39 124 176 70 40 50 Q FS6035D T- 25S For 8xD, 12xD machining, it is recommended to use a short diameter holder to process the guide hole. And the processing parameters, use ( ) recommended parameters. 739 740

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы