Каталог TooTool техническая информация 2 - страница 165

Навигация

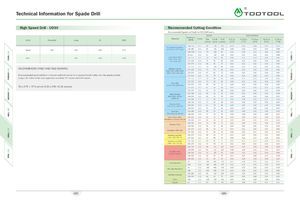

Technical Information for Spade Drill A\ High Speed Drill - UD30 Recommended Cutting Condition Recommended Speed and Feeds for HSS Drill Inserts Speed Feed (mm/rev) Holer Extended Long XL 3XLV Material FIardness(BHN) Grade TiN TiALN TiCN 9.50 to 13.00 to 17.60 to 24.50 to 35.10 tom/minm/minm/min12.5017.5024.4035.0047.90 100-150 G12 96 128 115 0.20 0.30 0.38 0.45 0.53 Free Machining Steel Speed 0.90 0.85 0.80 0.75 1118, 1215, 12L14, etc 150-200 G12 85 110 100 0.18 0.28 0.35 0.40 0.48 200+250 G12 79 104 90 0.15 0.25 0.33 0.38 0.43 85 -125 G12 91 119 110 0.20 0.25 0.33 0.43 0.48 Feed 0.95 0.90 0.90 Low Carbon Steel 125 -175 G12 79 104 90 0.18 0.25 0.33 0.40 0.451010, 1020, 1025, 1522, 1144, etc. 175 - 225 G12 73 95 82 0.15 0.23 0.30 0.38 0.43 225 - 275 G12 64 83 75 0.13 0.23 0.30 0.38 0.43 125 -175 G12 79 104 90 0.18 0.25 0.33 0.40 0.45 RECOMMENDED SPEED AND FEED EXAMPLE: Medium CarbonSteel 1030, 1040, 1050,175-225 G12 73 95 84 0.15 0.23 0.30 0.38 0.43 1527, 1140, 1151, etc. 225-275 G12 67 83 72 0.15 0.23 0.30 0.38 0.43 If recommended speed and feed is 50m/min and 0.20 mm/rev for a standard length holder, then the speed and feed 275-325 G12 55 70 62 0.13 0.20 0.28 0.35 0.40 using a 3XL holder in the same application would be 37.5 m/min and 0.18 mm/rev. 125 -175 G12 76 99 87 0.18 0.25 0.33 0.40 0.45 175-225 G12 70 92 80 0.15 0.23 0.30 0.38 0.43 Alloy Steel 50 x 0.75 = 37.5 m/min 0.20 x 0.90 =0.18 mm/rev 4140, 5140, 8640, etc. 225 - 275 G12 64 83 72 0.15 0.23 0.30 0.38 0.43275 -325G126176680.130.200.280.350.40 325 -375 G12 52 67 60 0.10 0.18 0.25 0.33 0.38 High Strength 225 -300 G12 49 61 55 0.15 0.23 0.25 0.30 0.38 Alloy 4340, 4330V, 300-350 G12 43 55 49 0.13 0.20 0.23 0.28 0.35 300M, etc. 350-400 G12 37 49 43 0.10 0.18 0.20 0.25 0.30 100-150 G12 73 95 84 0.20 0.28 0.35 0.40 0.45 Structural Steel A36, A516, A285, etc 150-250 G12 61 76 68 0.15 0.25 0.30 0.35 0.40 250-350 G12 55 70 62 0.13 0.23 0.28 0.30 0.35 Tool Steel 150-200 G12 49 67 58 0.10 0.18 0.23 0.28 0.33 H13, H12, A4, S3, etc 200-250 G12 37 52 45 0.10 0.18 0.23 0.28 0.33 High Temp, Alloy 140-220 G12 24 32 28 0.10 0.18 0.23 0.28 0.33 Hastelloy B, Inconel 600, etc 220-310 G12 18 26 22 0.10 0.15 0.20 0.25 0.30 140-220 G12 30 38 32 0.10 0.18 0.23 0.28 0.30 Titanium Alloy 220-310 G12 24 33 28 0.10 0.15 0.20 0.35 0.30 185 - 275 G12 49 64 57 0.17 0.22 0.29 0.35 0.40 Aerospace Alloy S82 275-350 G12 37 49 43 0.14 0.19 0.27 0.30 0.35 Stainless steel 400 185-275 G12 49 64 57 0.17 0.22 0.29 0.35 0.40 series, 416, 420, etc. 275 -350 G12 37 49 43 0.14 0.19 0.27 0.30 0.45 Stainless steel 300 135 -185 G12 49 64 57 0.13 0.17 0.22 0.26 0.30 series, 304, 316, etc. 185 - 275 G12 37 49 43 0.11 0.14 0.20 0.22 0.25 120-150 G12 98 141 127 0.20 0.30 0.38 0.48 0.58 150-200 G12 82 122 102 0.18 0.28 0.33 0.43 0.53 Nodular, Grey, Ductile Cast Iron 200-220 G12 73 110 93 0.15 0.23 0.30 0.38 0.45 220-260 G12 64 95 79 0.13 0.20 0.28 0.33 0.38 260-320 G12 55 83 69 0.13 0.18 0.25 0.28 0.33 30 G12 366 460 410 0.25 0.38 0.45 0.50 0.55 Cast Aluminum 180 G12 244 306 275 0.23 0.33 0.40 0.45 0.50 30 G12 366 460 410 0.10 0.15 0.25 0.30 0.36 Wrought Aluminum 180 G12 244 306 275 0.20 0.28 0.36 0.45 0.40 100-200 G12 85 110 100 0.13 0.20 0.25 0.36 0.42 Aluminum Bronze 200-250 G12 64 94 79 0.10 0.15 0.18 0.25 0.33 Brass 100 G12 130 184 160 0.15 0.23 0.28 0.38 0.45 Copper 60 G12 80 120 100 0.05 0.08 0.10 0.15 0.25 685 686

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы