Каталог TooTool техническая информация 2 - страница 166

Навигация

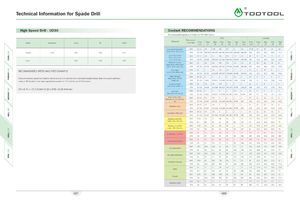

Technical Information for Spade Drill A\ High Speed Drill - UD30 Coolant RECOMMENDATIONS Recommended Speed and Feeds for HSS Drill Inserts HSS Carbide Holer Extended Long XL 3XLV Material Pressure orFlow rate 9.5to 13to 18to 25to 36to 51to 76to 9.5to 13to 18to 25to 36to12.5172435507610212.517243547 Free Machining Steel BAR 12-13 7-8 7-10 6-8 5-7 4 5-6 17-20 17 15 15 20 Speed 0.90 0.85 0.80 0.75 1118, 1215, 12L14, etc LPM 9.5-9.8 10.6-11.4 16.7-19.7 26.5-30.3 45.4-53.0 114-125 144-167 122 16.3 25.2 41.5 71.9 Low Carbon Steel BAR 11-12 5-6 5-7 4-6 4-5 2-3 3-5 18 11 11 12 9 1010, 1020, 1025, Feed 1522, 1144, etc. LPM 9.1-9.5 9.1-98 14.0-15.9 22.7-26.5 416-45.4 98-114 125-144 11.4 13.3 20.6 36.5 62.00.950.900.90 Medium Carbon BAR 11 5-6 5-6 4-5 3-5 2-3 3-5 17 10 10 10 8 Steel 1030, 1040, 1050, 1527, 1140, 1151, etc. LPM 8.7-9.1 8.7-98 13.6-15.5 18.9-22.7 37.9-45.4 98-114 125-144 113 12.5 20.0 33.8 57.0 RECOMMENDED SPEED AND FEED EXAMPLE: Alloy Steel BAR 11 5 5-6 3-5 3-4 2 3 17 9 10 8 74140, 5140, 8640, etc.LPM8.7-9.183-9.1132-14818.9-22.7- 3L9 4L698-106114-1251L112.319.330.055.8 High Strength BAR 10-11 4 3 2 2 1-2 2 15 5 4 3 3 If recommended speed and feed is 50m/min and 0.20 mm/rev for a standard length holder, then the speed and feed Alloy 4340, 4330V, using a 3XL holder in the same application would be 37.5 m/min and 0.18 mm/rev. 300M, etc. LPM 8.7-9.1 7.9-83 11.0-117 15.1-18.9 26.5-30.3 79-87 87-98 10.4 9.1 12.6 188 33.6 Structural Steel BAR 11 5-6 5-6 3-4 3 2 3 16 9 8 7 5 A36, A516, A285, etc LPM 8.7-9.1 9.1-98 132-14.8 18.9-22.7 34.1-37.9 87-98 114-125 108 12.0 17.5 27.8 47.1 50 x 0.75 = 37.5 m/min 0.20 x 0.90 =0.18 mm/rev Tool Steel BAR 10-11 4 3 2 2 1-2 2 15 5 5 3 3 H13, H12, A4, S3, etc LPM 8.7-9.1 7.9-83 11.0-11.7 15.1-18.9 26.5-30.3 79-87 87-98 10.4 9.1 13.6 19.7 36.5 High Temp, Alloy BAR 10-11 4-5 3A 2 2 2 3 17 11 12 11 9 Hastelloy B, Inconel 600, etc LPM 8.7-9.1 83-8.7 11.7-12. 15.1-18.9 26.5-30.3 87-98 125 111 13.5 21.9 35.4 62.0 BAR 10-11 4-5 3-4 2 2 2 3 17 11 12 11 9 Titanium Alloy LPM 8.7-9.1 83-8.7 11.7-12.1 15.1-18.9 26.5-30.3 87-98 125 111 13.5 21.9 35.4 62.0 BAR 10-11 4-5 3-4 2 2 2 3 17 11 12 11 9 Aerospace Alloy S82 LPM 8.7-9.1 83-8.7 11.7-12.1 15.1-18.9 26.5-30.3 87-98 125 111 13.5 21.9 35.4 62.0 Stainless steel 400 BAR 11.8 5.9 52 3.8 3.5 2 3.1 22.7 16.5 17.9 17.2 13.1 series, 416, 420, etc. LPM 9.5 9.8 14 23 38 98 117 13 16.3 26.3 44.2 75 Stainless steel 300 BAR 11.8 5.9 52 3.8 3.5 2 3.1 22.7 16.5 17.9 17.2 13.1 series, 304, 316, etc. LPM 9.5 9.8 14 23 38 98 117 13 16.3 26.3 44.2 75 BAR 11 4.5 42 2.8 2.4 2 2.4 15.5 7.2 6.2 6.2 5.5 SG/Nodular Cast Iron LPM 9.1 8.7 12.5 19 34 98 106 10.7 10.8 15.4 26.5 48.7 BAR 11 4.5 42 2.8 2.4 2 2.4 15.5 7.2 6.2 6.2 5.5 Grey/white cast Iron LPM 9.1 8.7 12.5 19 34 98 106 10.7 10.8 15.4 26.5 48.7 BAR 14.5 12.4 15.8 11 8.6 3.5 5.5 24.1 22.0 21.7 19.6 13.8 Cast Aluminum LPM 10 14 23 34 61 125 159 13.4 18.8 29 47.2 77 BAR 14.5 12.4 15.8 11 8.6 3.5 5.5 24.1 22.0 21.7 19.6 13.8 Wrought Aluminum LPM 10 14 23 34 61 125 159 13.4 18.8 29 47.2 77 BAR 12.8 8.3 9.65 7.95 6.9 3.5 62 20 16.5 16.5 15.2 12 Aluminum Bronze LPM 9.6 11.4 19.7 303 53 125 167 122 16.3 25.2 41.5 71.9 BAR 11 4.5 42 2.8 2.4 2 2.4 24.1 22.0 21.7 19.6 13.8 Brass LPM 9.1 8.7 12.5 19 34 98 106 13.4 18.8 29 47.2 77 BAR 12.8 83 9.65 7.95 6.9 3.5 62 20 16.5 16.5 15.2 12 Copper LPM 9.6 11.4 19.7 30.3 53 125 167 122 16.3 25.2 41.5 71.9 BAR 10.7 42 3.5 2 2 1.7 2 14.5 5.2 4.8 3.4 3.1 Hardness Steel LPM 9.1 83 11.7 19 30 87 98 10.4 9.1 13.6 19.7 36.5 687 688

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Общий каталог TooTool

Общий каталог TooTool Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы