Общий каталог Sumitomo 2019 - 2020 - страница 807

Навигация

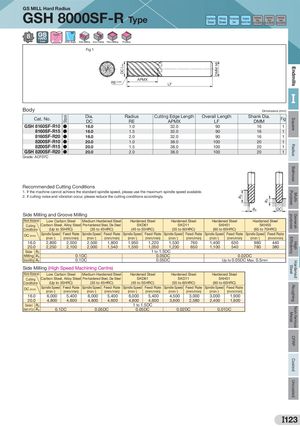

Stock 0 DC -0.030 DMM h6 apap apap UncoatedCoatedCFRPNon-ferrousMetalRoughingHardenedSteelHighEfficiencyGeneral-purposeMulti-PurposeBallnoseRadiusSquareEndmills GS MILL Hard Radius GSH 8000SF-R Type CarbonSteel AlloySteelPre-hardenedSteelTemperedSteel/Die SteelHardenedSteel45 to 55HRCHardenedSteel55 to 60HRCHardenedSteel60 to 65HRC Corner Flutes Coat Helix Angle Side Milling Groove Finishing Face Milling Profiling Fig 1 APMX RE±0.020 LF I Body Dimensions (mm) Cat. No. Dia.DC Radius Cutting Edge Length Overall LengthREAPMXLF Shank Dia. DMM Fig GSH 8160SF-R10 ● 16.0 1.0 32.0 90 16 1 GSH 8160SF-R15 ● 16.0 1.5 32.0 90 16 1 GSH 8160SF-R20 ● 16.0 2.0 32.0 90 16 1 GSH 8200SF-R10 ● 20.0 1.0 38.0 100 20 1 GSH 8200SF-R15 ● 20.0 1.5 38.0 100 20 1 GSH 8200SF-R20 ● 20.0 2.0 38.0 100 20 1 Grade: ACF07C ae Recommended Cutting Conditions 1. If the machine cannot achieve the standard spindle speed, please use the maximum spindle speed available. 2. If cutting noise and vibration occur, please reduce the cutting conditions accordingly. ae DC Side Milling and Groove Milling Work Material Low Carbon Steel Medium Hardened Steel Hardened Steel Hardened Steel Hardened Steel Hardened Steel Cutting Carbon Steel, Alloy Steel Pre-hardened Steel, Die Steel SKD61 SKD11 SKH51 SKH55 Conditions (Up to 35HRC) (35 to 45HRC) (45 to 55HRC) (55 to 60HRC) (60 to 65HRC) (65 to 70HRC) DC (mm) Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) 16.0 2,800 2,500 2,500 1,800 1,950 1,220 1,530 760 1,400 630 980 440 20.0 2,250 2,100 2,000 1,540 1,550 1,050 1,230 650 1,100 540 780 380 Side ap 1 to 1.5DCMillingae0.1DC0.05DC 0.02DDCC Groove Mil ing ap 0.1DC 0.05DC Up to 0.05DC Max. 0.5mm Side Milling (High Speed Machining Centre) Work Material Low Carbon Steel Medium Hardened Steel Hardened Steel Hardened Steel Hardened Steel Cutting Carbon Steel, Alloy Steel Pre-hardened Steel, Die Steel SKD61 SKD11 SKH51 Conditions (Up to 35HRC) (35 to 45HRC) (45 to 55HRC) (55 to 60HRC) (60 to 65HRC) DC (mm) Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate Spindle Speed Feed Rate (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) (min-1) (mm/min) 16.0 6,000 5,400 6,000 5,400 6,000 5,400 4,500 3,000 3,000 1,900 20.0 4,800 4,600 4,800 4,600 4,800 4,600 3,600 2,580 2,400 1,600 Standard ap 1 to 1.5DC Depth of Cut ae 0.1DC 0.05DC 0.05DC 0.02DC 0.01DC I123

Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Общий каталог Sumitomo 2018 - 2019

Общий каталог Sumitomo 2018 - 2019