Каталог Sumitomo модульные системы для револьверных головок токарных станков - страница 9

Навигация

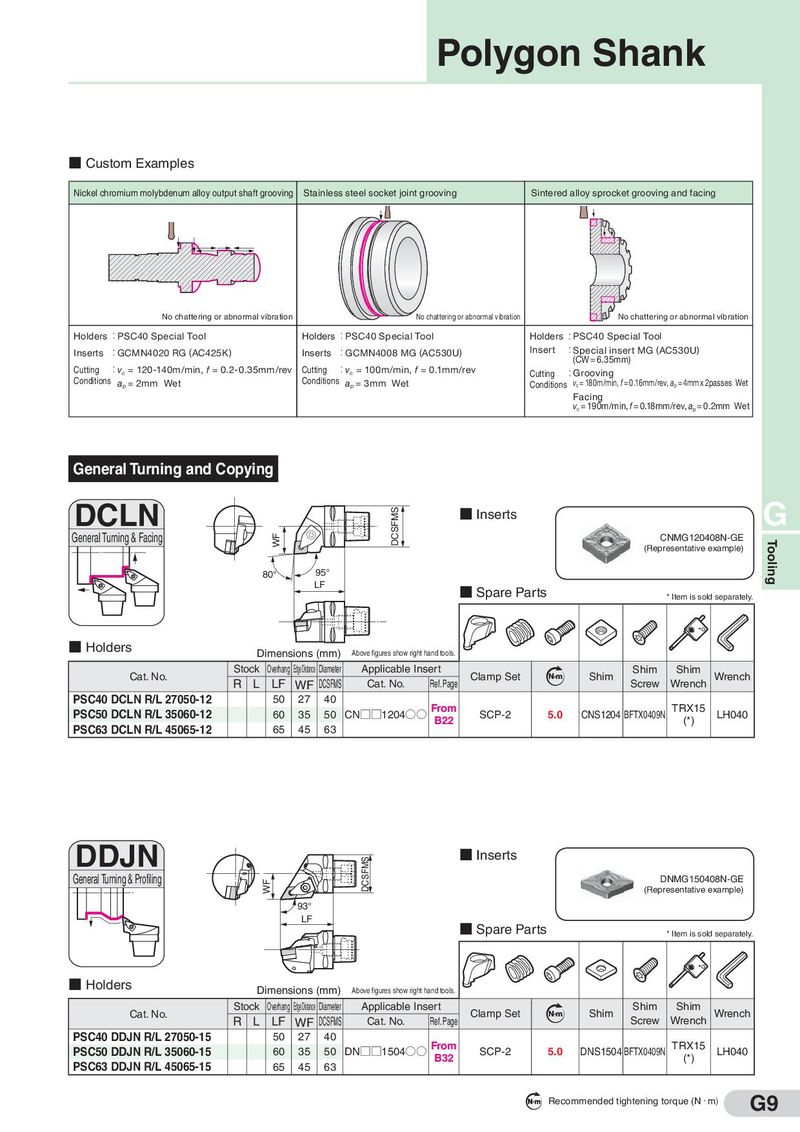

Polygon Shank ■ Custom Examples Nickel chromium molybdenum alloy output shaft grooving Stainless steel socket joint grooving Sintered alloy sprocket grooving and facing No chattering or abnormal vibration No chattering or abnormal vibration No chattering or abnormal vibration Holders :PSC40 Special Tool Holders :PSC40 Special Tool Holders : PSC40 Special Tool Inserts :GCMN4020 RG (AC425K) Inserts :GCMN4008 MG (AC530U) Insert :Special insert MG (AC530U) (CW = 6.35mm) Cutting :vc = 120-140m/min, f = 0.2-0.35mm/rev Cutting :vc = 100m/min, f = 0.1mm/rev Cutting :Grooving Conditions ap = 2mm Wet Conditions ap = 3mm Wet Conditions vc = 180m/min, f = 0.16mm/rev, ap = 4mm x 2passes Wet Facing vc = 190m/min, f = 0.18mm/rev, ap = 0.2mm Wet General Turning and Copying DCLN DCSFMS ■ Inserts G General Turning & Facing WF CNMG120408N-GE Tooling (Representative example) 80° 95° LF ■ Spare Parts * Item is sold separately. ■ Holders Dimensions (mm) Above figures show right hand tools. Cat. No. Stock Overhang EdgeDistance Diameter Applicable Insert Clamp Set Nm Shim Shim Shim Wrench R L LF WF DCSFMS Cat. No. Ref. Page Screw Wrench PSC40 DCLN R/L 27050-12 50 27 40 From TRX15 PSC50 DCLN R/L 35060-12 60 35 50 CN□□1204○○ B22 SCP-2 5.0 CNS1204 BFTX0409N (*) LH040 PSC63 DCLN R/L 45065-12 65 45 63 DDJN DCSFMS ■ Inserts General Turning & Profiling WF DNMG150408N-GE (Representative example) 93° LF ■ Spare Parts * Item is sold separately. ■ Holders Dimensions (mm) Above figures show right hand tools. Cat. No. Stock Overhang EdgeDistance Diameter Applicable Insert Clamp Set Nm Shim Shim Shim Wrench R L LF WF DCSFMS Cat. No. Ref. Page Screw Wrench PSC40 DDJN R/L 27050-15 50 27 40 From TRX15 PSC50 DDJN R/L 35060-15 60 35 50 DN□□1504○○ B32 SCP-2 5.0 DNS1504 BFTX0409N (*) LH040 PSC63 DDJN R/L 45065-15 65 45 63 Recommended tightening torque (N・m) G9

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012