Каталог Sumitomo модульные системы для револьверных головок токарных станков - страница 2

Навигация

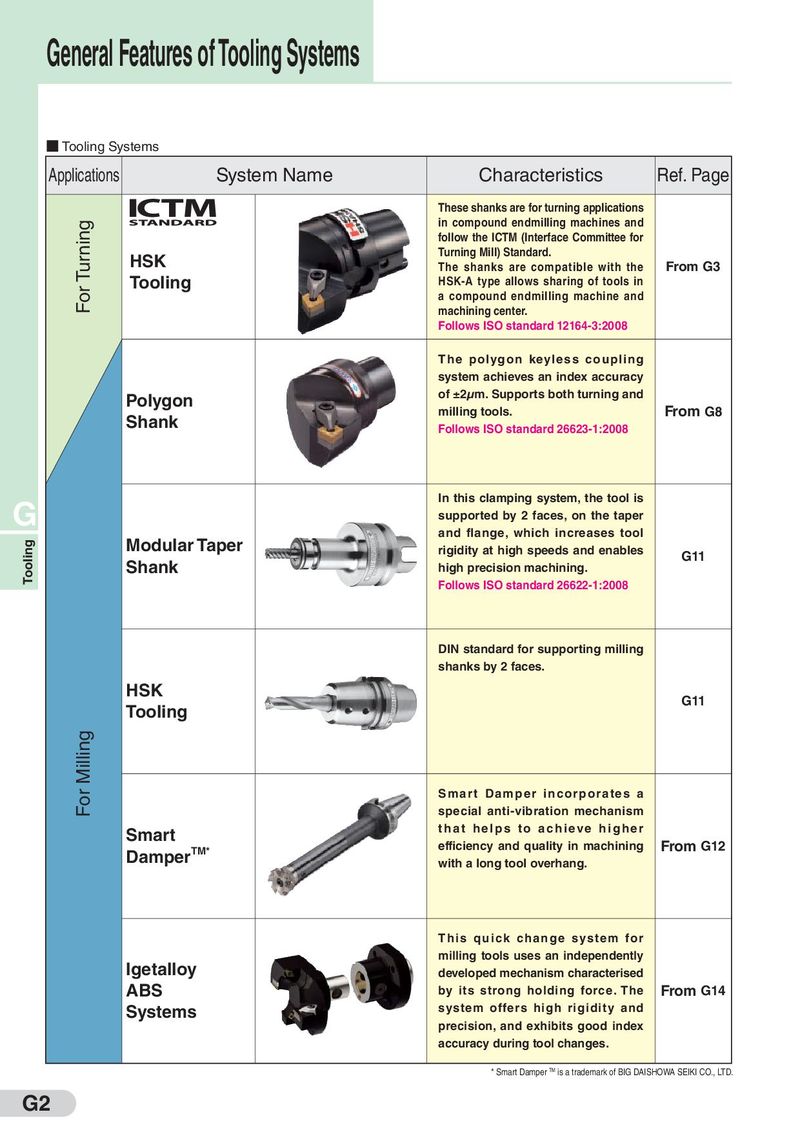

General Features of Tooling Systems ■ Tooling Systems Applications System Name Characteristics Ref. Page These shanks are for turning applications For Turning in compound endmilling machines and follow the ICTM (Interface Committee for HSK Turning Mill) Standard. The shanks are compatible with the From G3 Tooling HSK-A type allows sharing of tools in a compound endmilling machine and machining center. Follows ISO standard 12164-3:2008 The polygon keyless coupling system achieves an index accuracy Polygon of ±2μm. Supports both turning and Shank milling tools. From G8 Follows ISO standard 26623-1:2008 G In this clamping system, the tool is supported by 2 faces, on the taper Modular Taper and flange, which increases tool Tooling rigidity at high speeds and enables G11 Shank high precision machining. Follows ISO standard 26622-1:2008 DIN standard for supporting milling shanks by 2 faces. HSK G11 Tooling For Milling Smart Damper incorporates a special anti-vibration mechanism Smart that helps to achieve higher DamperTM* efficiency and quality in machining From G12 with a long tool overhang. This quick change system for milling tools uses an independently Igetalloy developed mechanism characterised ABS by its strong holding force. The From G14 Systems system offers high rigidity and precision, and exhibits good index accuracy during tool changes. * Smart Damper TM is a trademark of BIG DAISHOWA SEIKI CO., LTD. G2

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012