Каталог Sumitomo модульные системы для револьверных головок токарных станков - страница 11

Навигация

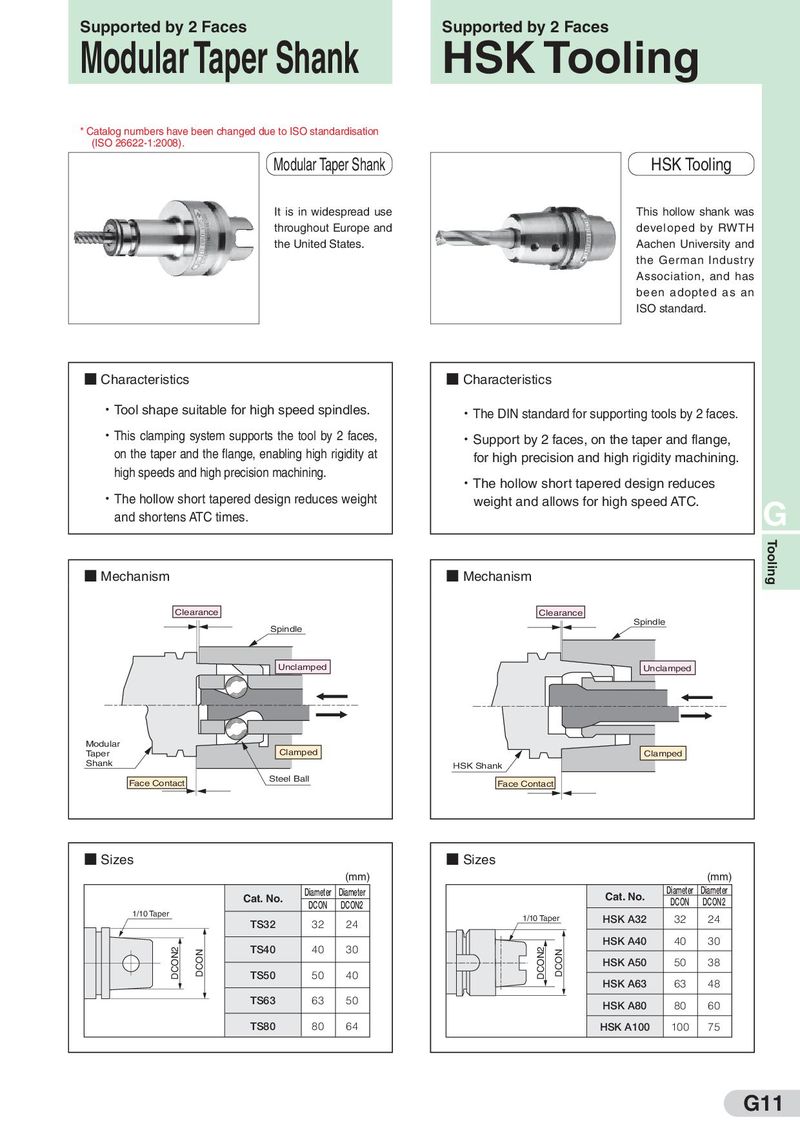

Supported by 2 Faces Supported by 2 Faces Modular Taper Shank HSK Tooling * Catalog numbers have been changed due to ISO standardisation (ISO 26622-1:2008). Modular Taper Shank HSK Tooling It is in widespread use This hollow shank was throughout Europe and developed by RWTH the United States. Aachen University and the German Industry Association, and has been adopted as an ISO standard. ■ Characteristics ■ Characteristics ・Tool shape suitable for high speed spindles. ・The DIN standard for supporting tools by 2 faces. ・This clamping system supports the tool by 2 faces, ・Support by 2 faces, on the taper and flange, on the taper and the flange, enabling high rigidity at for high precision and high rigidity machining. high speeds and high precision machining. ・The hollow short tapered design reduces ・The hollow short tapered design reduces weight weight and allows for high speed ATC. G and shortens ATC times. ■ Mechanism ■ Mechanism Tooling Clearance Clearance Spindle Spindle Unclamped Unclamped Modular Taper Clamped Clamped Shank HSK Shank Face Contact Steel Ball Face Contact ■ Sizes ■ Sizes (mm) (mm) Diameter Diameter Cat. No. Diameter Diameter Cat. No. DCON DCON2 DCON DCON2 1/10 Taper 1/10 Taper HSK A32 32 24 TS32 32 24 HSK A40 40 30 DCON2 DCON TS40 40 30 DCON2 DCON HSK A50 50 38 TS50 50 40 HSK A63 63 48 TS63 63 50 HSK A80 80 60 TS80 80 64 HSK A100 100 75 G11

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron

Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron Каталог Sumitomo специальные торцевые фрезы

Каталог Sumitomo специальные торцевые фрезы Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сплавы и режимы

Каталог Sumitomo сплавы и режимы Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012