Каталог Stellram токарный инструмент - страница 202

Навигация

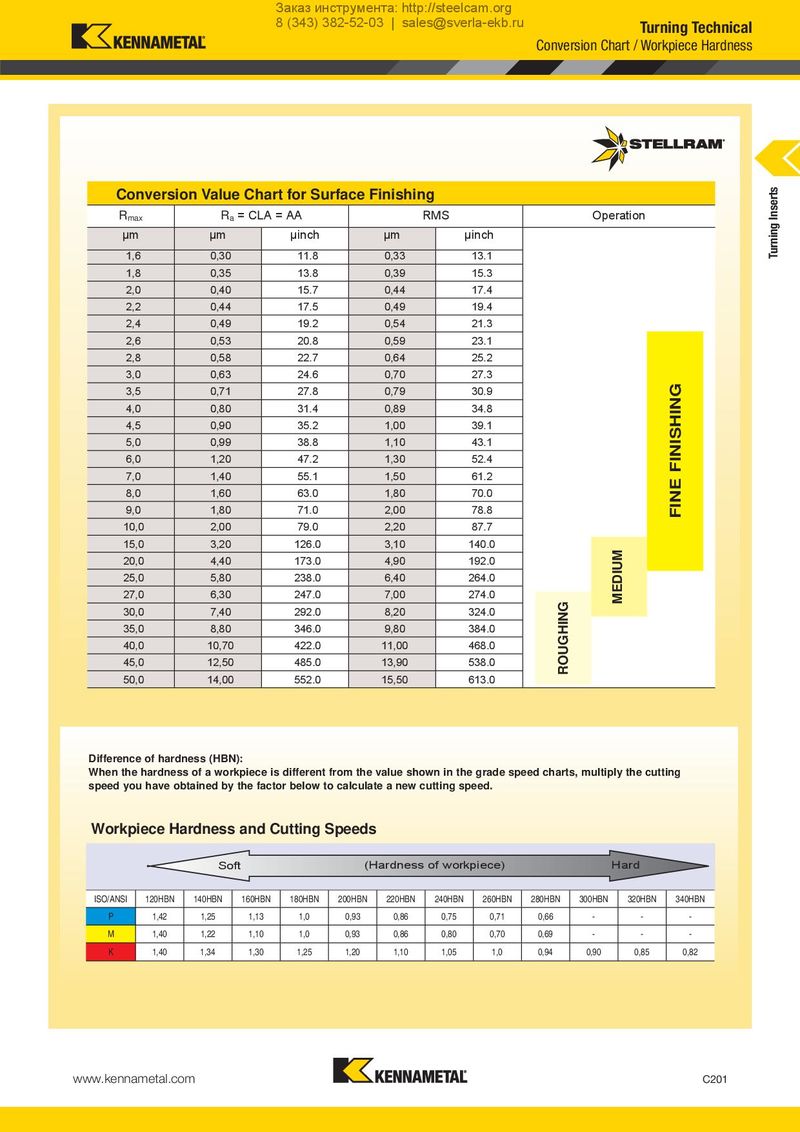

Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru Turning Technical Conversion Chart / Workpiece Hardness Conversion Value Chart for Surface Finishing Turning Inserts Rmax Ra = CLA = AA RMS Operation µm µm µinch µm µinch 1,6 0,30 11.8 0,33 13.1 1,8 0,35 13.8 0,39 15.3 2,0 0,40 15.7 0,44 17.4 2,2 0,44 17.5 0,49 19.4 2,4 0,49 19.2 0,54 21.3 2,6 0,53 20.8 0,59 23.1 2,8 0,58 22.7 0,64 25.2 3,0 0,63 24.6 0,70 27.3 3,5 0,71 27.8 0,79 30.9 FINE FINISHING 4,0 0,80 31.4 0,89 34.8 4,5 0,90 35.2 1,00 39.1 5,0 0,99 38.8 1,10 43.1 6,0 1,20 47.2 1,30 52.4 7,0 1,40 55.1 1,50 61.2 8,0 1,60 63.0 1,80 70.0 9,0 1,80 71.0 2,00 78.8 10,0 2,00 79.0 2,20 87.7 15,0 3,20 126.0 3,10 140.0 MEDIUM 20,0 4,40 173.0 4,90 192.0 25,0 5,80 238.0 6,40 264.0 27,0 6,30 247.0 7,00 274.0 ROUGHING 30,0 7,40 292.0 8,20 324.0 35,0 8,80 346.0 9,80 384.0 40,0 10,70 422.0 11,00 468.0 45,0 12,50 485.0 13,90 538.0 50,0 14,00 552.0 15,50 613.0 Difference of hardness (HBN): When the hardness of a workpiece is different from the value shown in the grade speed charts, multiply the cutting speed you have obtained by the factor below to calculate a new cutting speed. Workpiece Hardness and Cutting Speeds Soft (Hardness of workpiece) Hard ISO/ANSI 120HBN 140HBN 160HBN 180HBN 200HBN 220HBN 240HBN 260HBN 280HBN 300HBN 320HBN 340HBN P 1,42 1,25 1,13 1,0 0,93 0,86 0,75 0,71 0,66 - - - M 1,40 1,22 1,10 1,0 0,93 0,86 0,80 0,70 0,69 - - - K 1,40 1,34 1,30 1,25 1,20 1,10 1,05 1,0 0,94 0,90 0,85 0,82 www.kennametal.com C201

Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами